An auxiliary device for transporting large-scale drainage steel pipes for construction sites

An auxiliary device and steel pipe technology, which is applied in the direction of transportation and packaging, transportation objects, signal devices, etc., can solve the problem of unpredictability on the eve of collapse, and achieve the effect of avoiding swinging back and forth

Active Publication Date: 2022-06-03

安徽新红胜装饰工程有限公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the technical problem in the prior art that the rigid bolting in the process of transporting steel pipes leads to unpredictability on the eve of collapse, the present invention provides an auxiliary device for transporting large-scale drainage steel pipes for construction sites

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

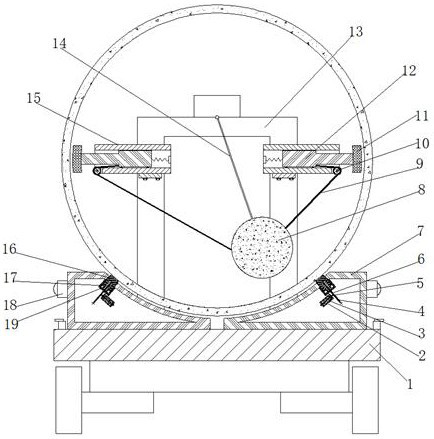

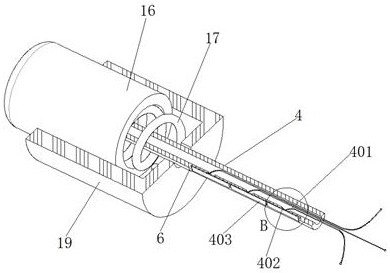

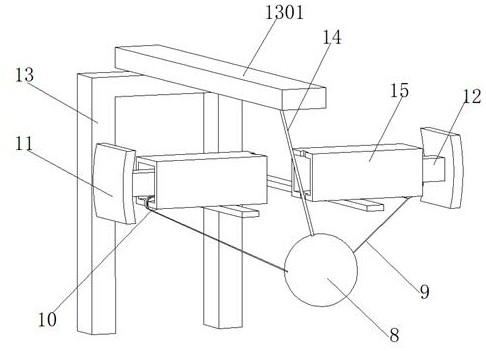

The invention belongs to the technical field of pipeline transportation, in particular to an auxiliary device for transportation of large-scale drainage steel pipes for construction sites. Aiming at the problem in the prior art that the steel pipes are rigidly bolted during the process of transporting steel pipes, the collapse can not be predicted before the collapse, the following proposals are proposed, including Two load-bearing boxes fixed on the upper surface of the flatbed car base are symmetrical to each other, and the upper surface of the two load-bearing boxes is reserved near the middle with an arc-shaped surface. The diameter of the arc-shaped surface is the same as the diameter of the steel pipe. There are round holes near the top. The present invention can be used when the steel pipe is deflected to one side too much during transportation, and the jacking column will drive the jacking pipe to slide upwards obliquely under the action of the return spring 2, and at this time, different metal sheets will be driven to match with each other in turn. The contact slide bar contacts to switch on different alarm circuits, thereby sending out different alarms.

Description

An auxiliary device for transporting large-scale drainage steel pipes for construction sites technical field The present invention relates to pipeline transportation technical field, relate in particular to a kind of auxiliary equipment for large-scale drainage steel pipe transportation for construction sites set. Background technique Existing steel pipe construction site is transferred to factory and transport in the hole, mostly adopts transport trailer or rented special vehicle to carry out, but When transporting large diameter and heavy steel pipes, there is a great risk. Generally, the width of transport vehicles is between 2 meters and 3 meters. Steel pipes with a diameter of more than 9 meters, such as steel pipes of more than 9 meters, are transported by conventional vehicles, and one end needs to be overhanging more than 3 meters, which can be transported on flat roads. If it needs to be transported under the conditions of steep slopes, many turns and uneven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60P3/40B60P7/16B60P7/135B60Q9/00

CPCB60P3/40B60P7/16B60P7/135B60Q9/00Y02A30/60

Inventor 葛欣悦丁倩文

Owner 安徽新红胜装饰工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com