Glue sheet placement and lamination weighing and lifting device and control method thereof

A lifting device and lamination technology, applied in the field of tire rubber machinery, can solve the problems of increased construction difficulty, heavy workload of workers, operator danger, etc., and achieve the effects of increasing output devices, increasing lamination devices, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

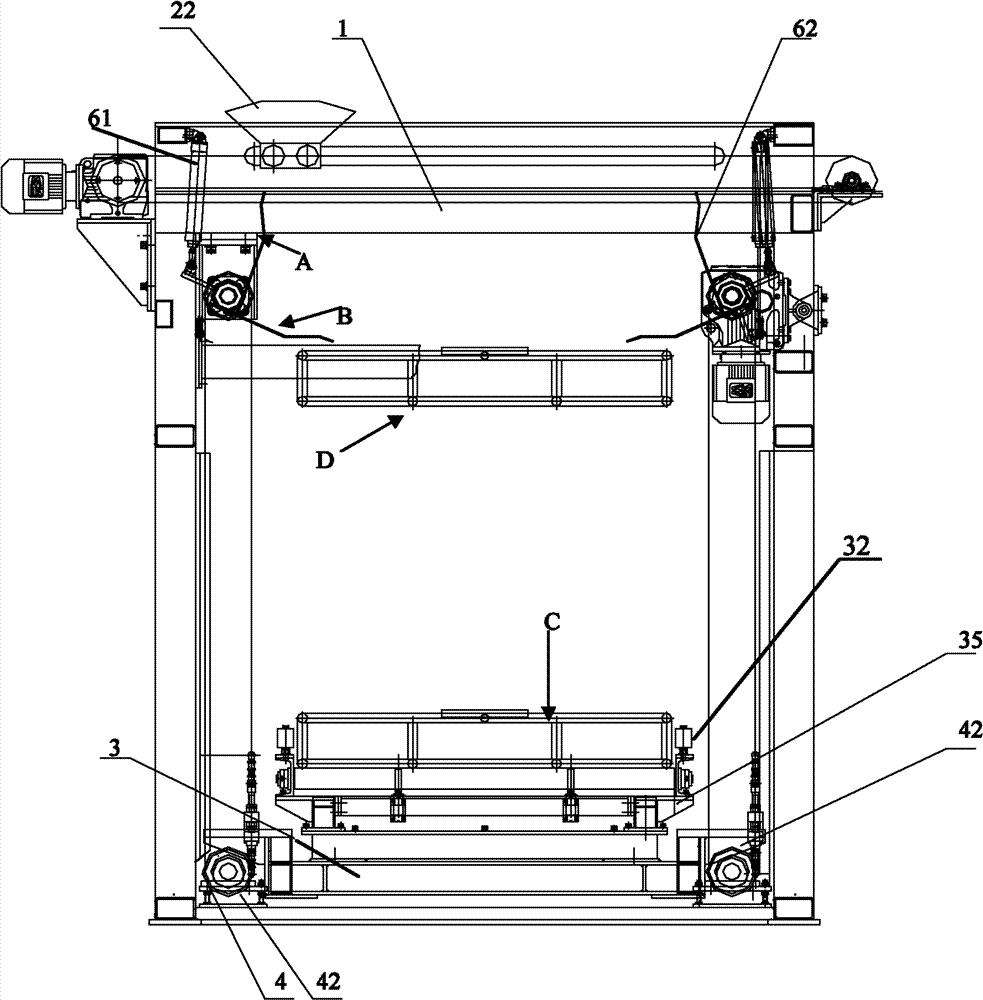

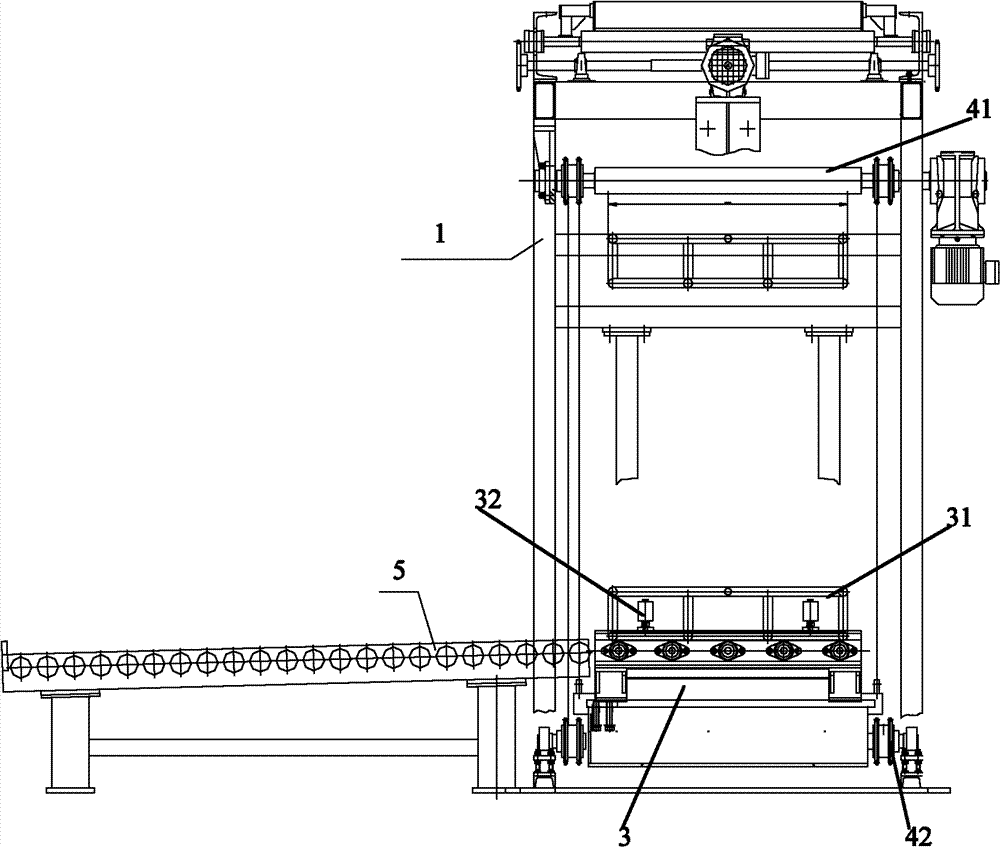

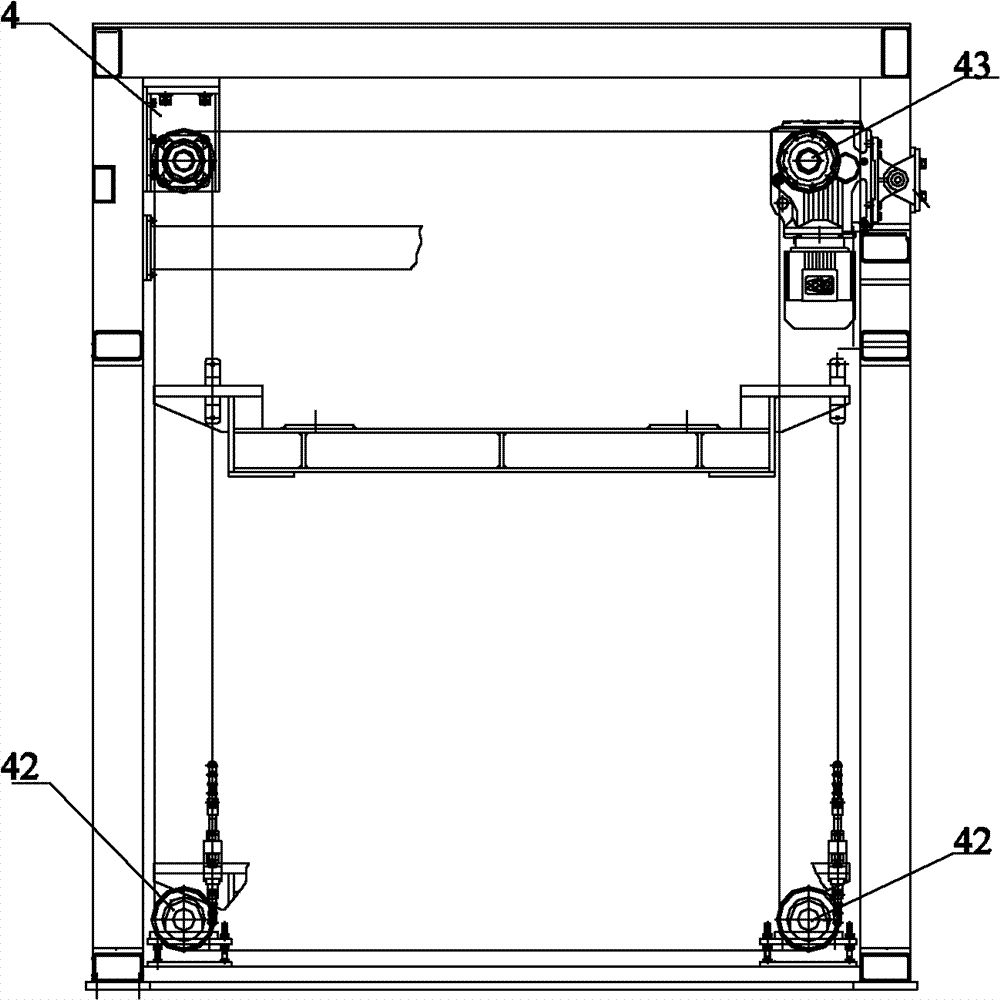

[0025] like Figure 1-4 As shown, the weighing and lifting device of the swing plate stack of the present invention includes a main frame 1 equipped with a lifting transmission device; a swing plate device installed on the top of the main frame 1; The lifting platform 3 that moves vertically up and down, the described lifting platform 3 is provided with an electronic scale, the material storage table is arranged on the electronic scale and the material storage table is placed with a material receiving tray 31, and the material receiving tray 31 output device 5.

[0026] The swing device includes a swing tube 22 that can swing left and right along the top track of the main frame 1 and its driving device. The drive device of the swing tube 22 includes a drive motor reducer fixed on the top side of the main frame 1 21, the chain 23 that can drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com