A kind of composite machining method of high-volume aluminum-based silicon carbide threaded hole

An aluminum-based silicon carbide and composite processing technology, which is applied in the composite processing of aluminum-based silicon carbide threaded holes and the composite processing of high-volume aluminum-based silicon carbide threaded holes, can solve the problems of screw hole chipping, low processing efficiency, and screw hole chipping. Insufficient tooth strength and other problems, to achieve the effect of slowing down the contact state, ensuring the quality of the processed surface, improving the processing quality and the accuracy of the screw tooth shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below.

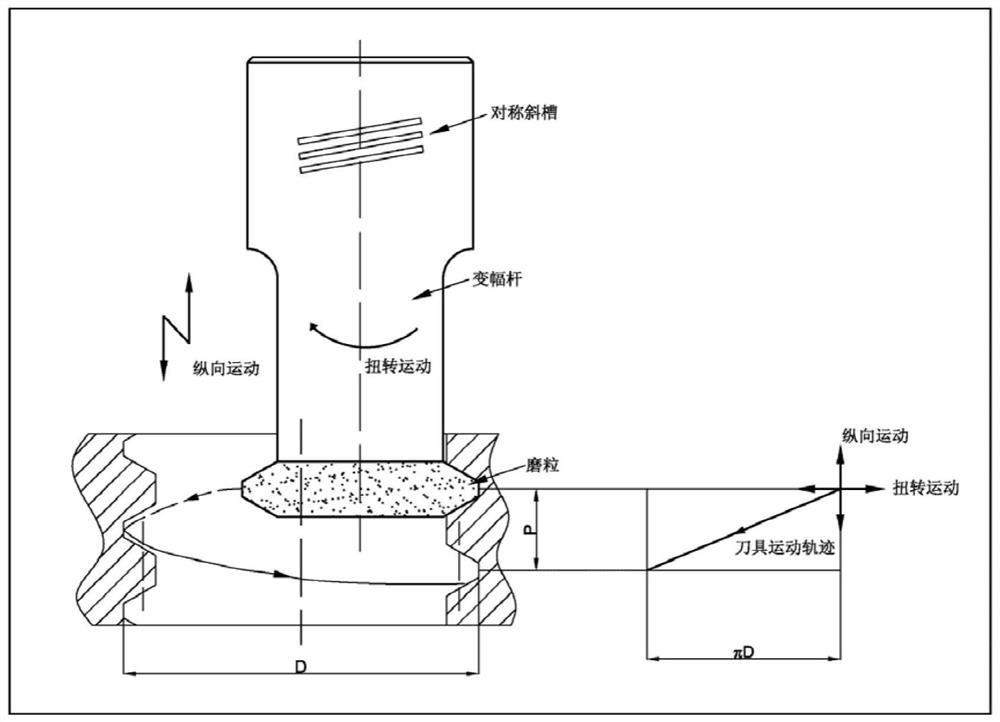

[0027] High-volume SiCp / Al materials have typical hard and brittle characteristics. In view of the problems of the current prior art, the phenomenon of serious chipping at the exit in small hole drilling, and the large area of surface defects caused by particles falling off in thread processing, the present invention provides a method. A milling-grinding-integrated composite machining method based on multi-dimensional ultrasonic vibration, through tool design and process parameter optimization, the unfavorable machining state is alleviated, and the thread machining quality and efficiency are improved.

[0028] The basic idea of the method of the invention is as follows: the threaded hole is processed on the multi-dimensional ultrasonic vibration machine tool by using a milling tool, the thread processing is completed by means of the tool path design of the milling process during the processing, and the micro-cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com