Welding device with automatic reversing function and application method thereof

A welding device and automatic reversing technology, applied in auxiliary devices, combination devices, separation methods, etc., can solve problems such as troublesome and low efficiency, and achieve the effects of expanding the scope of use, improving work efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

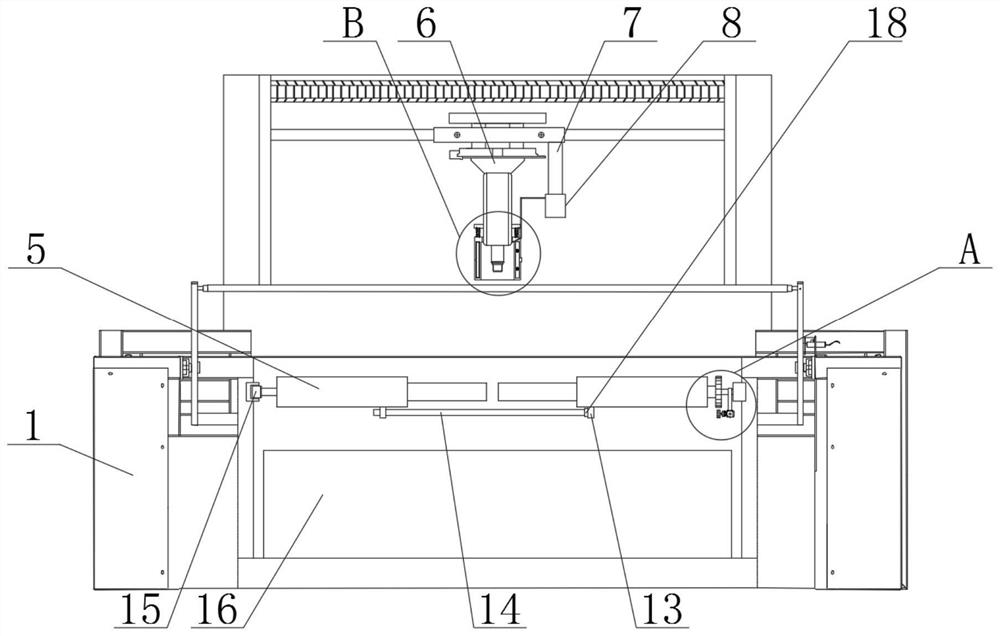

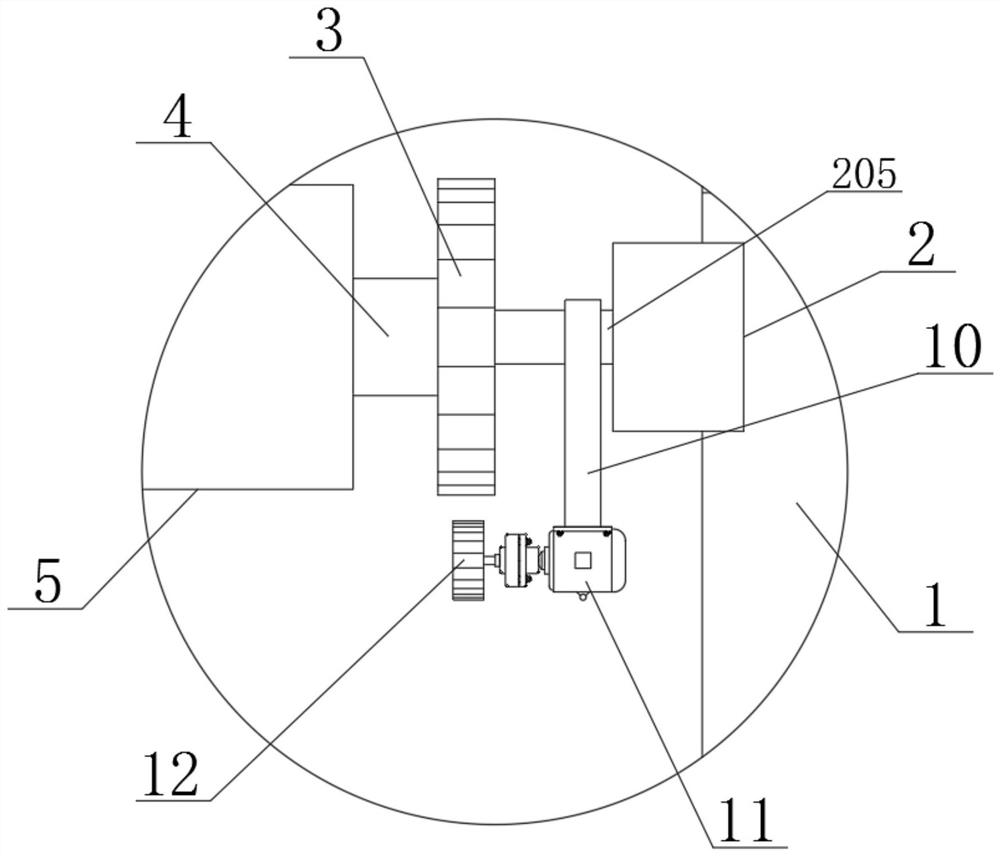

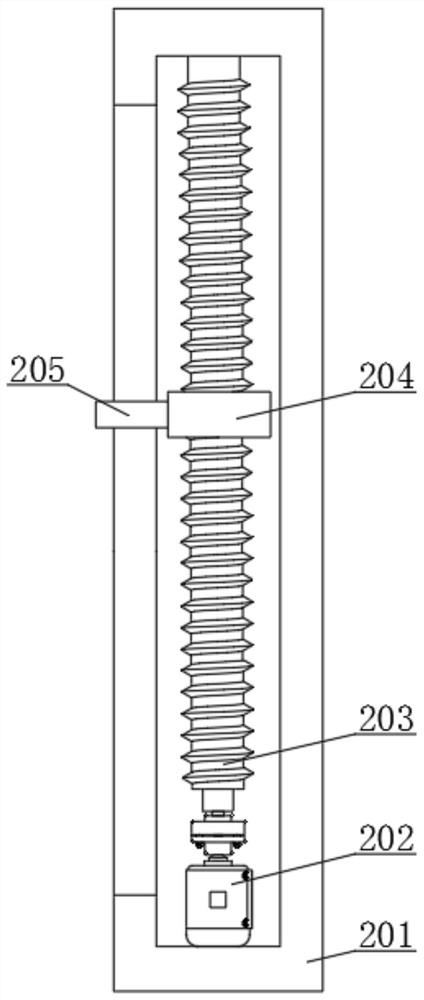

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 , the present invention provides a technical solution:

[0034]A welding device with an automatic reversing function and its use method, comprising welding equipment 1 and a moving mechanism 2, a welding torch 6 is fixedly connected to the upper surface of the welding equipment 1, and a protective mechanism 9 is fixedly connected to the outer side of the welding torch 6, and the protective mechanism 9 Including connecting ring 901 and guiding telescopic column 902, the inner side of connecting ring 901 is fixedly connected with welding torch 6, and the lower end surface of connecting ring 901 is fixedly connected with guiding telescopic column 902 distributed left and right, guiding telescopic column 902 ensures that protective frame 904 can move up and down The other ends of the guiding telescopic column 902 are fixedly connected with a protective frame...

Embodiment 2

[0042] In embodiment 2, the same part as embodiment 1 will not be repeated, the difference is that when the columnar part is welded, it is placed on the inside of the clamping block 507 at this time, and it is welded through the arc groove on the inside. Clamping work, at this time, the synchronous column 14 drives the magnetic block 18 to still engage with the limit cylinder 13. After adjusting the threaded handle 504, the welding gun 6 is then lowered to carry out the welding work. 11 make it drive the driving gear 12 to rotate, the driving gear 12 drives the driven gear 3 to rotate, and the driven gear 3 drives the connecting block 4 to rotate, thereby driving the clamping mechanism 5 to rotate 90°, then stop, and its magnetic block 18 and the limit The cylinder 13 is separated, and then the reversing motor 11 is started again to completely reverse the cylindrical part by 360° to ensure its welding quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com