Dry cleaning device

A technology for dry cleaning equipment and target objects, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as inability to handle small-sized PCB boards, achieve the possibility of avoiding oxidation, and enhance The effect of the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

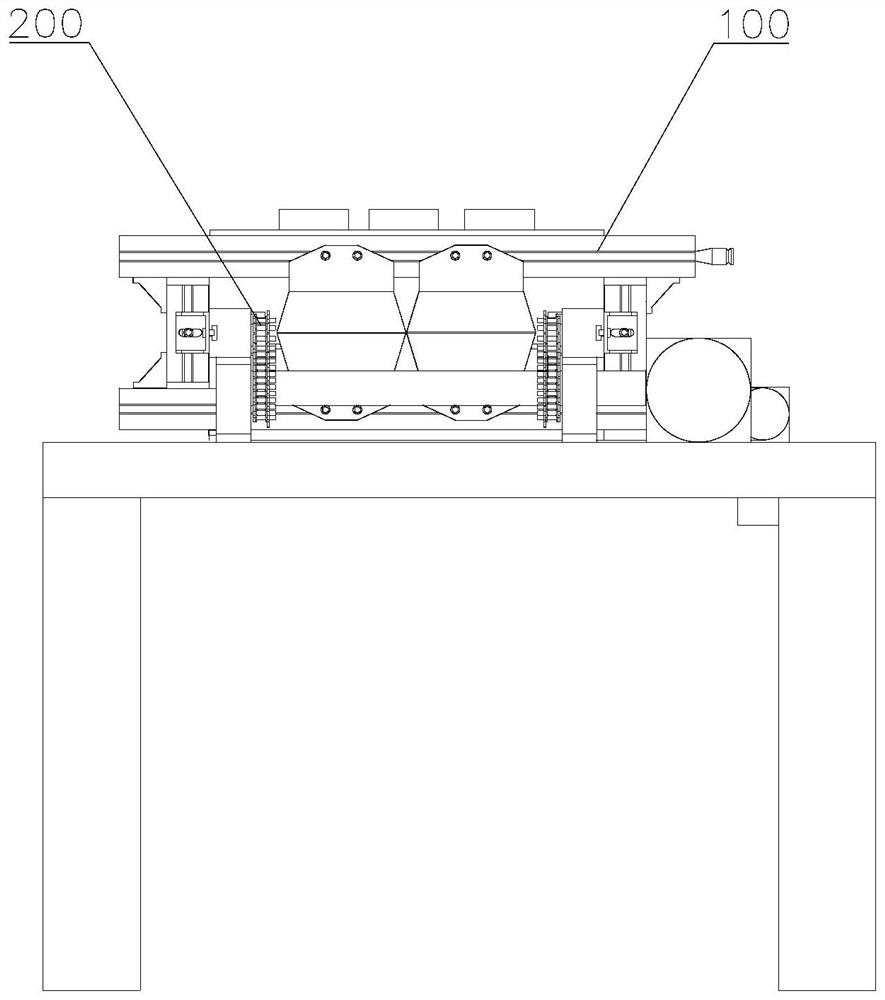

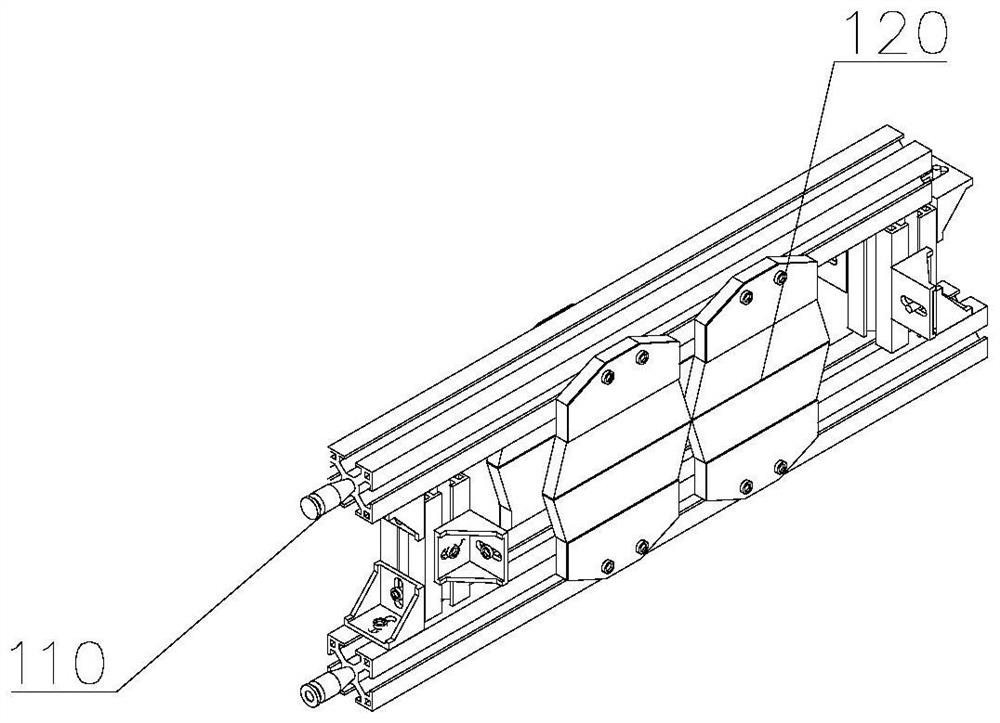

[0034] see figure 1 as well as figure 2 , figure 1 It is a view from a certain angle of view of the dry cleaning device in the first embodiment of the present invention; figure 2 It is a schematic view of the structure of the dust removal mechanism in the first embodiment of the present invention.

[0035] In this embodiment, a dry cleaning device is provided, including: a transmission mechanism 200 and a dust removal mechanism 100 disposed near the transmission mechanism 200;

[0036] The transmission mechanism 200 is used for transmitting the target object;

[0037] The dust removal mechanism 100 is used for outputting high-pressure airflow to the target object to clean the dust of the target object.

[0038] In the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com