An airborne camera back focus anti-loosening locking structure

A camera and lens technology, used in image communication, aircraft parts, televisions, etc., can solve the problems of inconvenient adjustment and complex structure of the focal length locking mechanism, reduce the difficulty of operation, facilitate electromagnetic compatibility, waterproof and good sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

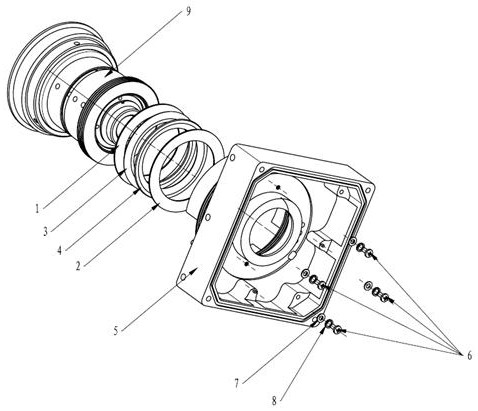

[0023] like figure 1 shown.

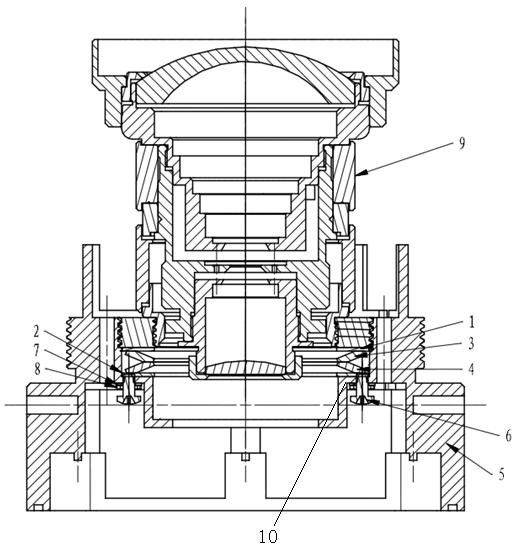

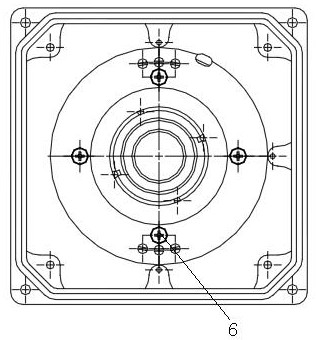

[0024] An airborne camera back focus locking structure, which includes a mesh flat pad 1, a flat pad 2, a first disc spring 3 and a second disc spring 4, such as figure 2 As shown, in the specific implementation, the first disc spring 3 and the second disc spring 4 can also be realized by similar springs or spring assemblies. 2, the mesh flat pad 1, the flat pad 2, the first disc spring 3 and the second disc spring 4 are coaxially installed in the lens mount 5, and the flat pad 2 and the three through the lens mount 5 above( image 3 There are four uniformly distributed cross symmetrical screws 6 against each other, and the cross symmetrical screws 6 are equipped with small flat washers 7 and small spring washers 8. After the cross symmetrical screws 6 pass through the small spring washers 8 and the small flat washers 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com