Tabletting type vacuum high-temperature electric connector capable of being remotely operated

An electrical connector and remote operation technology, which is applied in the field of sheet-type vacuum high-temperature electrical connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the remote-operated chip-type vacuum high-temperature electrical connector of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

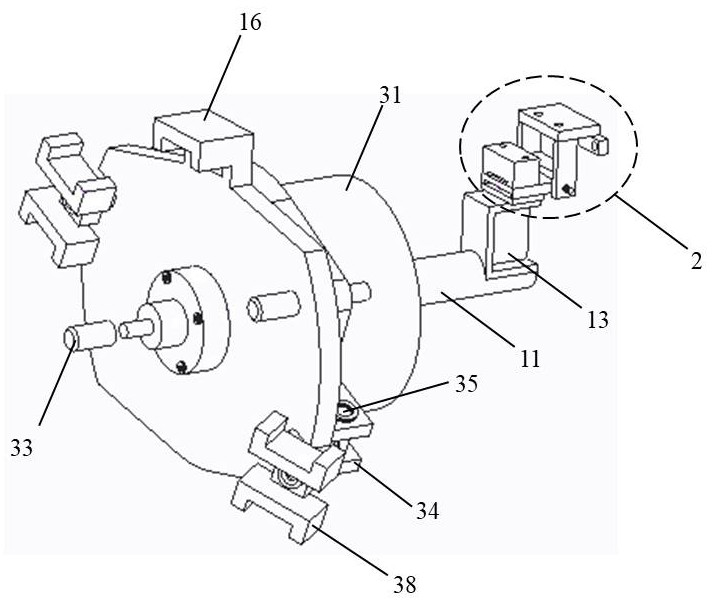

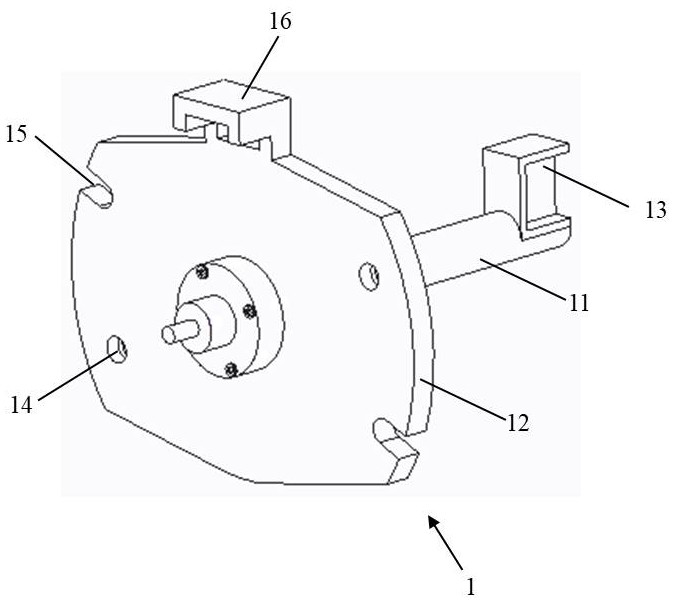

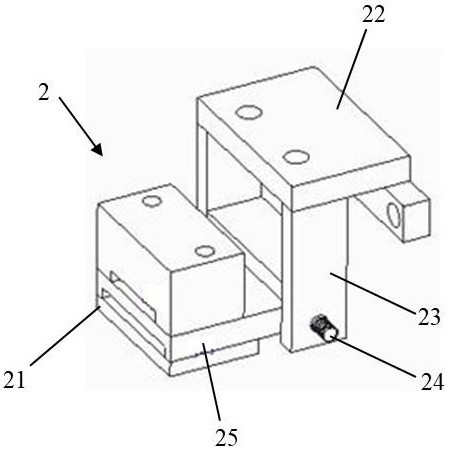

[0040] like figure 1 As shown in the figure, a tablet-type vacuum high-temperature electrical connector capable of remote operation includes a long-rod electrode mechanism 1, a tablet-press electrode mechanism 2, and a guide mechanism 3;

[0041] The long rod electrode mechanism 1 includes a long electrode rod 11 and a mounting plate 12, one end of the long electrode rod 11 passes through the mounting plate 12, and a connection structure 13 is provided at the other end; two guide holes 14 arranged diagonally are formed on the mounting plate 12, Its edge forms two rotating slots 15 arranged diagonally, and the guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com