Quadrature oscillation simulation device and method for measuring anti-scouring performance of test piece

A technology of orthogonal oscillation and simulation devices, which is applied in the field of orthogonal oscillation simulation devices, can solve the problems of extensiveness, poor experiment reusability, and difficulty in truly reflecting the anti-scourability of materials, etc., to achieve easy manipulation, improved convenience, and improved intuitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

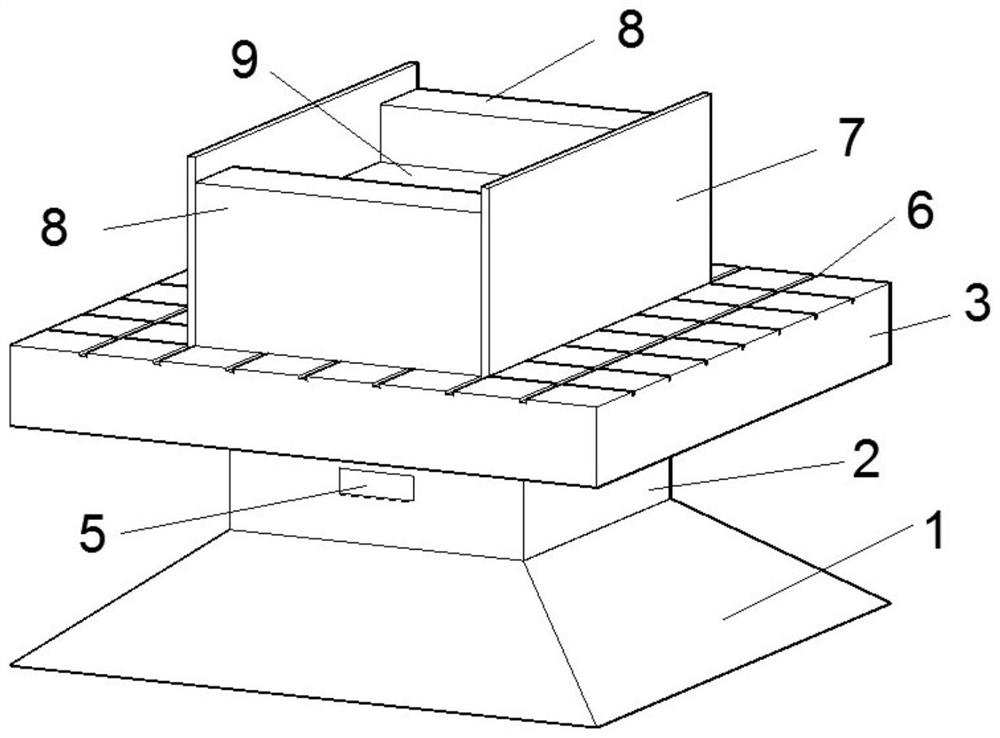

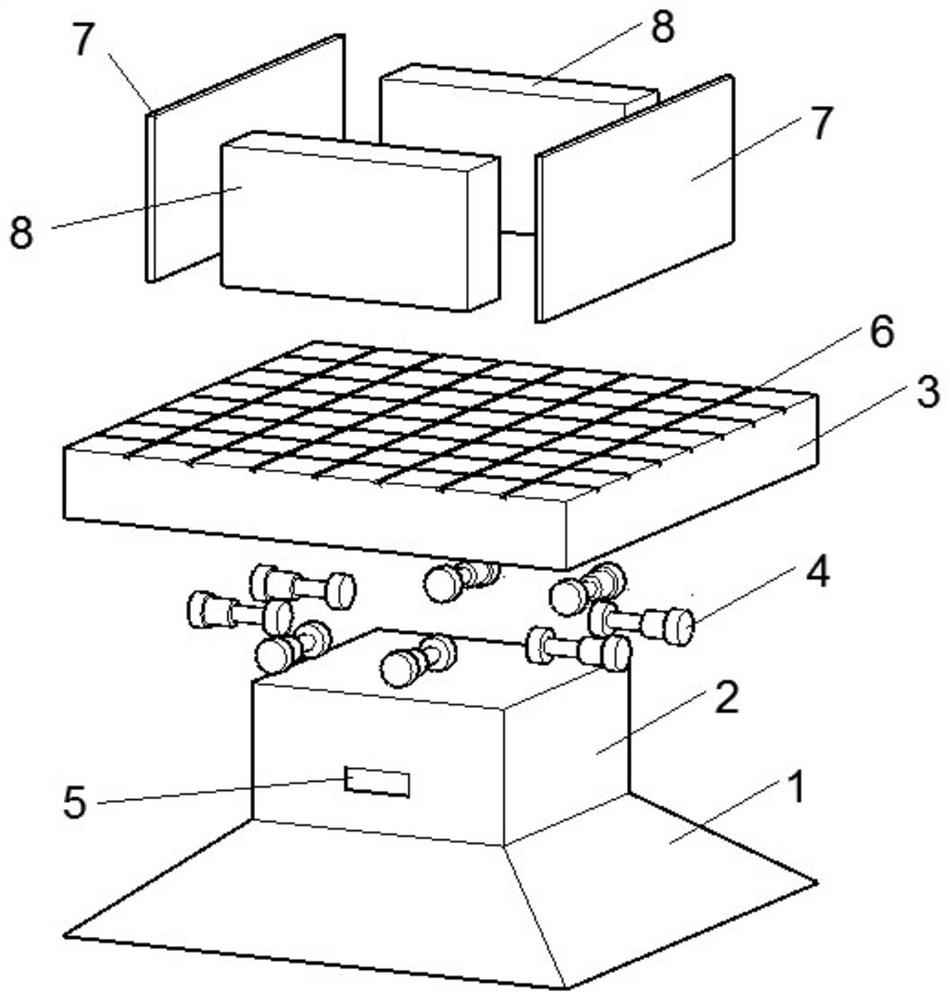

[0030] see figure 1 and figure 2 , a kind of orthogonal oscillation simulation device for measuring the anti-erosion performance of the test piece of the present invention comprises a horizontally arranged base 1, a base 2 is arranged on the base 1, a sliding bottom plate 3 is arranged on the base 2, and the sliding bottom plate 3 8 electric jacks 4 arranged horizontally are installed between the base 2, and the 8 electric jacks 4 are distributed along the orthogonal direction of the horizontal plane. A controller 5 is arranged on the top, and the controller 5 is electrically connected with the electric jack 4 to control the movement of the electric jack 4. The upper surface of the sliding bottom plate 3 is provided with a chute 6, and several chutes 6 are provided. The sliding bottom plate 3 is provided with The baffle 7, the baffle 7 is assembled with the sliding bottom plate 3 through the chute 6, there are 2 to 4 baffles 7, the baffle 7 and the test piece 8 are spliced ...

Embodiment 2

[0032] This embodiment is the same as Embodiment 1 except for the following content.

[0033] see figure 2 , the sliding bottom plate 3 is assembled with the baffle plate 7 to form a shock assembly, the test piece 8 is fixed by the baffle plate 7, the sliding bottom plate 3 is provided with multi-sized chute 6, and the corresponding baffle plate 7 is selected according to the size of the test piece, so that the baffle plate 7 is assembled with the sliding bottom plate 3 through the chute 6.

Embodiment 3

[0035] This embodiment is the same as Embodiment 1 except for the following content.

[0036] Base 1 and base 2 are rigidly connected and fixed on the experimental platform. Base 2 and sliding bottom plate 3 are connected by electric jack 4. One end of electric jack 4 is connected to base 2 and the other end is connected to sliding bottom plate 3. Orthogonal movement drives the oscillating component to generate horizontal oscillating movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com