Descending flue heating base of combustion furnace

A technology for heating bases and flues, applied in heating methods, lighting and heating equipment, combustion methods, etc., can solve problems such as loss and waste of heat energy, and achieve the effect of convenient operation and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

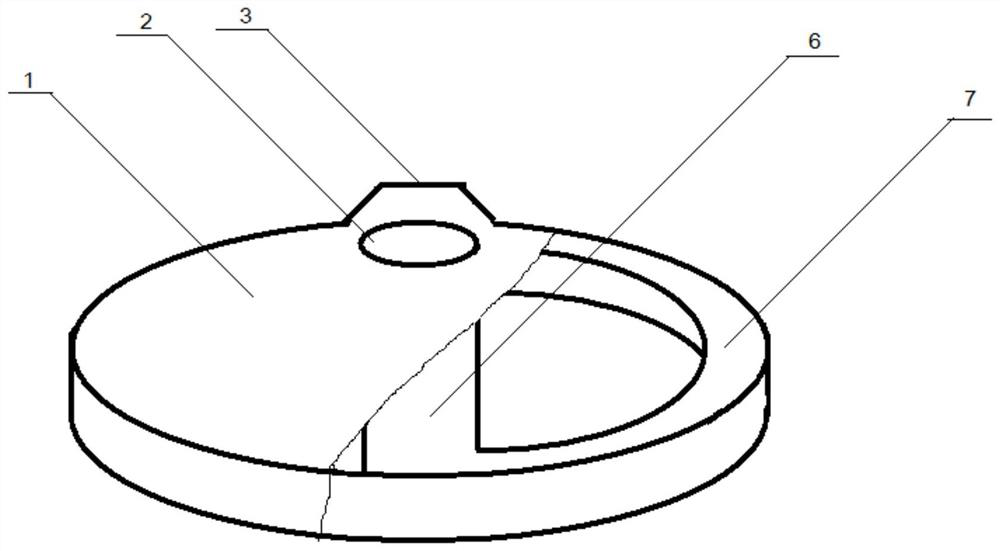

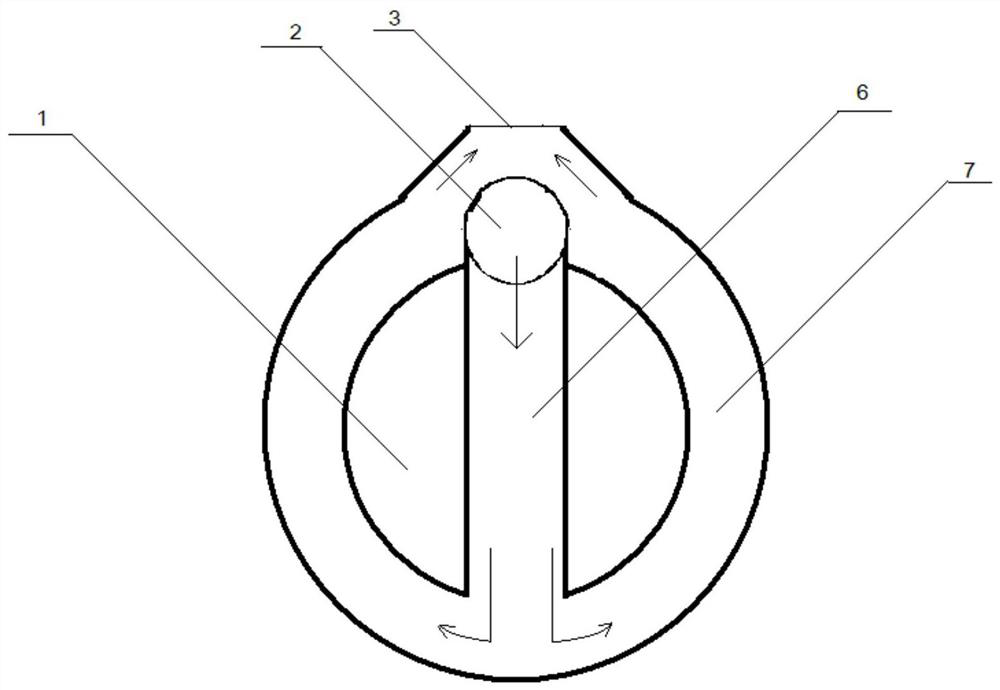

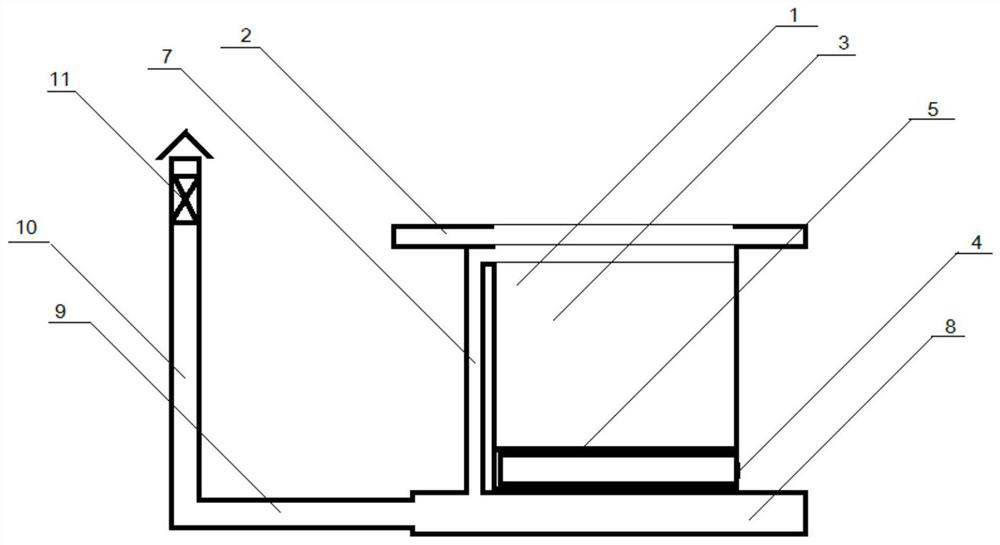

[0016] Embodiment 1: A heating base for the downflow flue of a combustion furnace. The base body 1 is a flat cylinder. The base body 1 is provided with a straight flue 6 that traverses the center point and an annular flue 7 surrounding it. The base The upper surface of the main body 1 is provided with a smoke inlet 2 connected to the downward flue, and the outer side of the smoke inlet 2 of the base body 1 is provided with an outwardly protruding smoke outlet 3; the two ends of the straight flue 6 are respectively connected to the On the smoke inlet 2 and the annular flue 7, the two ends of the annular flue 7 are respectively connected to the straight flue 6 and the smoke exhaust port 3, the flue gas of the burner enters the smoke inlet 2 from the downward flue, and the flue gas After entering the smoke inlet 2, it passes through the center of the base body 1 through the straight flue 6, and the smoke is divided into two parts at the rear of the straight flue 6 and enters the a...

Embodiment 2

[0017] Embodiment 2: A heating base for the downward flue of a combustion furnace. The base body 1 is a flat cylinder. The base body 1 is provided with a straight flue 6 that traverses the center point and an annular flue 7 surrounding it. The base The upper surface of the main body 1 is provided with a smoke inlet 2 connected to the downward flue, and the outer side of the smoke inlet 2 of the base body 1 is provided with an outwardly protruding smoke outlet 3; the two ends of the straight flue 6 are respectively connected to the On the smoke inlet 2 and the annular flue 7, the two ends of the annular flue 7 are respectively connected to the straight flue 6 and the smoke exhaust port 3, the flue gas of the burner enters the smoke inlet 2 from the downward flue, and the flue gas After entering the smoke inlet 2, it passes through the center of the base body 1 through the straight flue 6, and the smoke is divided into two parts at the rear of the straight flue 6 and enters the a...

Embodiment 3

[0018] Embodiment 3: A heating base for the downward flue of a combustion furnace. The base body 1 is a flat cylinder. The base body 1 is provided with a straight flue 6 across the center point and an annular flue 7 surrounding it. The base The upper surface of the main body 1 is provided with a smoke inlet 2 connected to the downward flue, and the outer side of the smoke inlet 2 of the base body 1 is provided with an outwardly protruding smoke outlet 3; the two ends of the straight flue 6 are respectively connected to the On the smoke inlet 2 and the annular flue 7, the two ends of the annular flue 7 are respectively connected to the straight flue 6 and the smoke exhaust port 3, the flue gas of the burner enters the smoke inlet 2 from the downward flue, and the flue gas After entering the smoke inlet 2, it passes through the center of the base body 1 through the straight flue 6, and the smoke is divided into two parts at the rear of the straight flue 6 and enters the annular f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com