A hydraulic punching coal water gas separator

A technology of water gas separator and hydraulic punching, which is applied in the direction of borehole/well parts, mining equipment, mining fluid, etc. It can solve the problems of turbulent flow of coal and water, and achieve the effect of easy processing, good effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

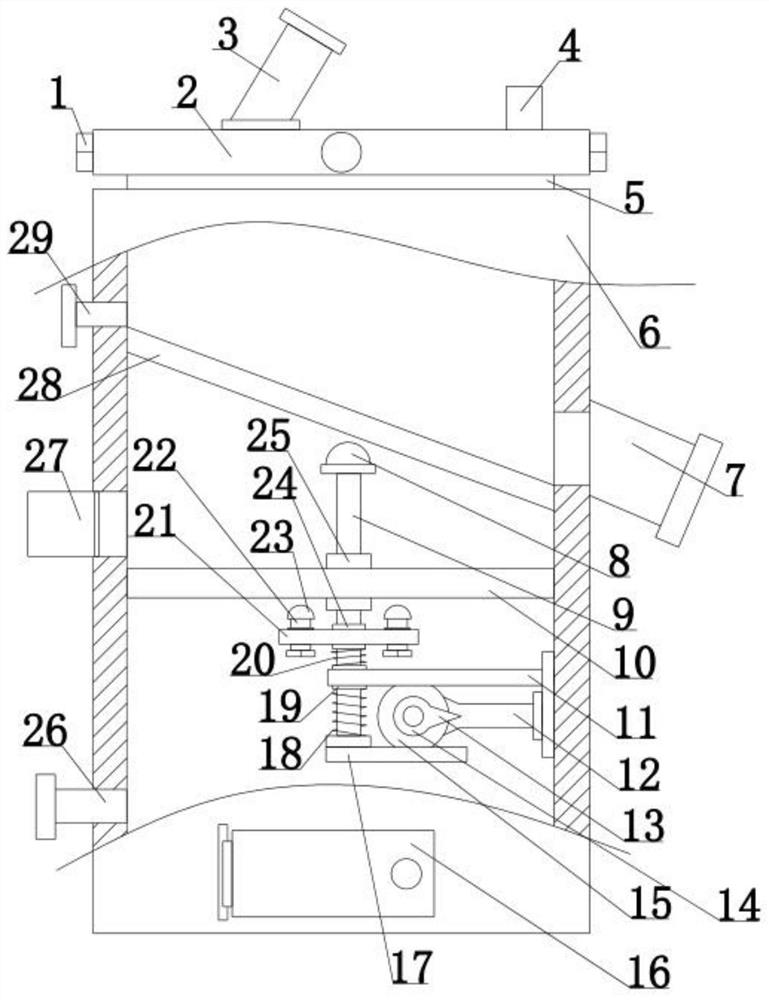

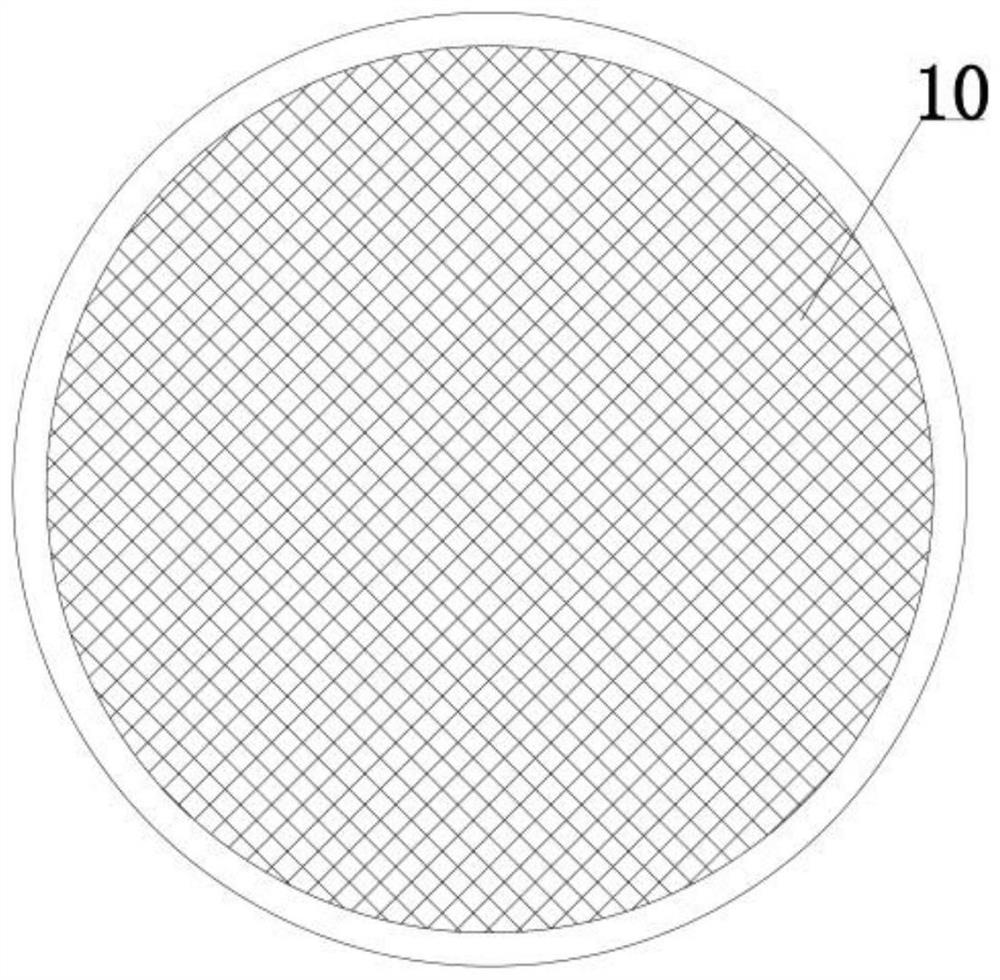

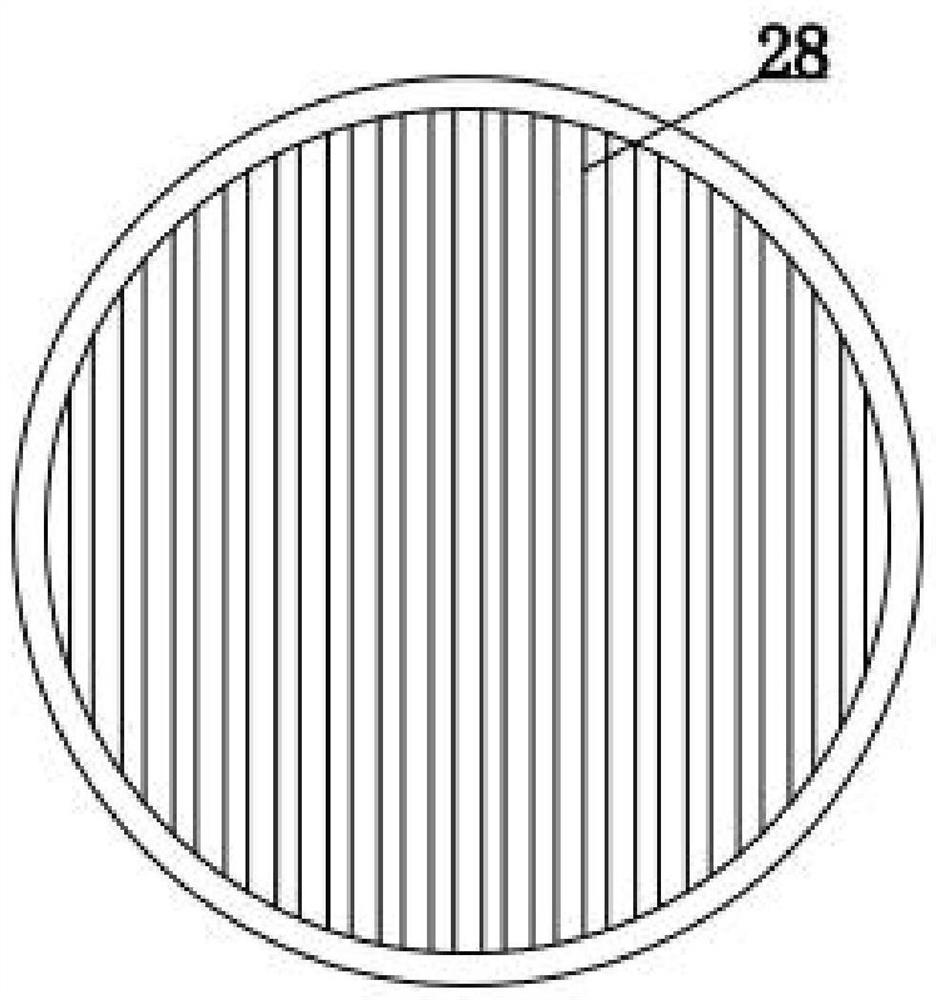

[0030] Such as Figure 1-3 As shown, the present embodiment provides an improved hydraulic punching coal-water gas separator, which mainly includes a separation barrel 6, a connection barrel 5 is fixedly installed on the upper side of the separation barrel 6, and a separation barrel cover 2 is installed on the top of the connection barrel 5. Between the barrel cover 2 and the connecting barrel 5, there are evenly installed barrel cover bolts 1, and the separation barrel cover 2 is fixedly installed with a water slag gas inlet 3 on the left side of the upper surface, and the gas outlet 4 is fixedly installed on the right side of the upper surface of the separation barrel cover 2. A water slag separation screen 28 is installed obliquely on the upper side of the bucket 6, and the left side of the water slag separation screen 28 is provided with an anti-blocking hole 29, and the right side of the water slag separation screen 28 is provided with a slag discharge port 7, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com