Cardanol sulfonate surfactant oil displacement agent and preparation method thereof

A technology of cardanol sulfonate and surface activity, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of ineffective recovery of moderately heavy oil reservoirs, large soil environment damage, and product Refractory degradation and other problems, to achieve the effect of shortening the reaction cycle, improving reaction efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

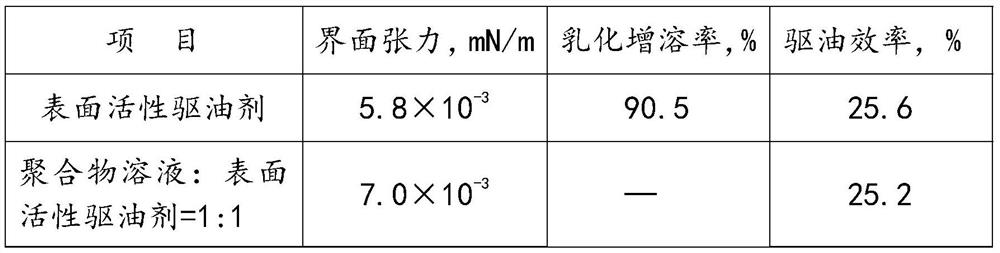

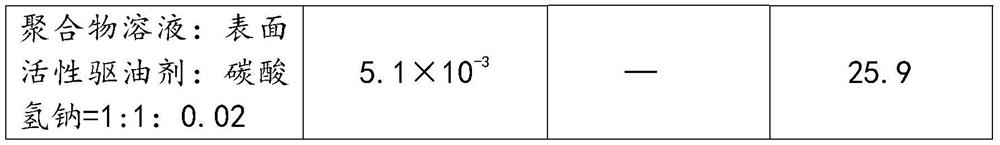

Examples

Embodiment 1

[0029] The embodiment of the present invention provides a kind of cardanol sulfonate surfactant oil displacement agent and preparation method thereof:

[0030] Add 50g of cardanol sulfonate in a 250mL beaker, add 15g of bis-quaternary ammonium salt and 8g of sodium secondary alkyl sulfonate, stir on a magnetic stirrer for 20min until uniform, then add 4g of coconut oil diethanolamide, 4g of Tween 80 and 1 g of triethanolamine, stirred on a magnetic stirrer for 30 min until uniform, then added 20 g of tap water and continued to stir for 10 min to obtain the finished product.

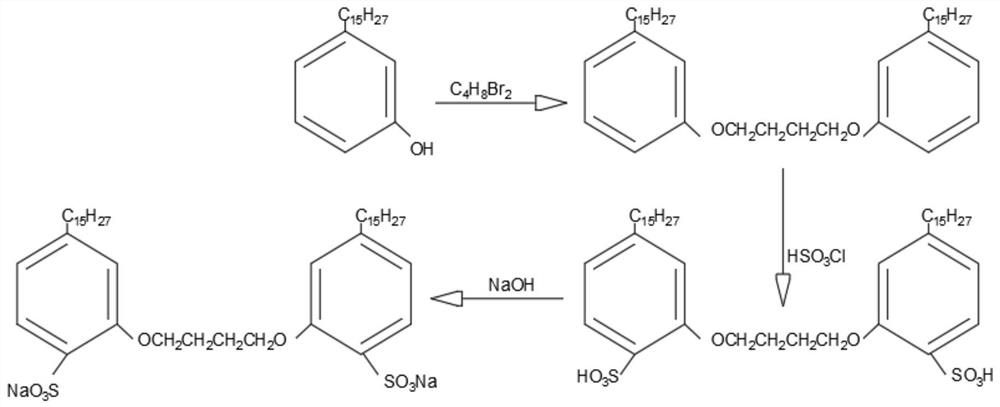

[0031] The preparation method of cardanol sulfonate surfactant is:

[0032] Step 1: etherification reaction; based on the total mass of 200g, measure 120g of cardanol and 60g of dibromobutane and add them to a four-necked flask equipped with a mechanical stirrer, a condenser, a dropping funnel, and a decompression device, and start stirring Mix evenly, connect the condensing device; measure 8g of catalys...

Embodiment 2

[0040] The embodiment of the present invention provides a kind of cardanol sulfonate surfactant oil displacement agent and preparation method thereof:

[0041] Add 50g of cardanol sulfonate in a 250mL beaker, add 15g of bis-quaternary ammonium salt and 8g of sodium secondary alkyl sulfonate, stir on a magnetic stirrer for 20min until uniform, then add 4g of coconut oil diethanolamide, 4g of Tween 80 and 1 g of triethanolamine, stirred on a magnetic stirrer for 30 min until uniform, then added 20 g of tap water and continued to stir for 10 min to obtain the finished product.

[0042] The preparation method of cardanol sulfonate surfactant is:

[0043] Step 1: etherification reaction. Based on the total mass of 200g, measure 130g of cardanol and 65g of dibromobutane and add them to a four-necked flask equipped with a mechanical stirrer, a condenser, a dropping funnel, and a decompression device, start stirring and mix evenly, and connect the condensing device; Measure 9g of ca...

Embodiment 3

[0050] The embodiment of the present invention provides a kind of cardanol sulfonate surfactant oil displacement agent and preparation method thereof:

[0051] Add 50g of cardanol sulfonate in a 250mL beaker, add 15g of bis-quaternary ammonium salt and 8g of sodium secondary alkyl sulfonate, stir on a magnetic stirrer for 20min until uniform, then add 4g of coconut oil diethanolamide, 4g of Tween 80 and 1 g of triethanolamine, stirred on a magnetic stirrer for 30 min until uniform, then added 20 g of tap water and continued to stir for 10 min to obtain the finished product.

[0052] The preparation method of cardanol sulfonate surfactant is:

[0053] Step 1: etherification reaction. Based on the total mass of 200g, measure 140g of cardanol and 70g of dibromobutane and add them to a four-necked flask equipped with a mechanical stirrer, a condenser, a dropping funnel, and a decompression device, start stirring and mix evenly, and connect the condensing device; Measure 10g of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com