Textile machine with yarn roll reverse rotation driving device

A technology of textile machinery and driving device, which is applied to the field of textile machinery with a yarn roll reversing driving device, can solve the problems of manpower and material resources, complicated control, poor safety, etc., and achieves the effect of reducing learning cost and simple operation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

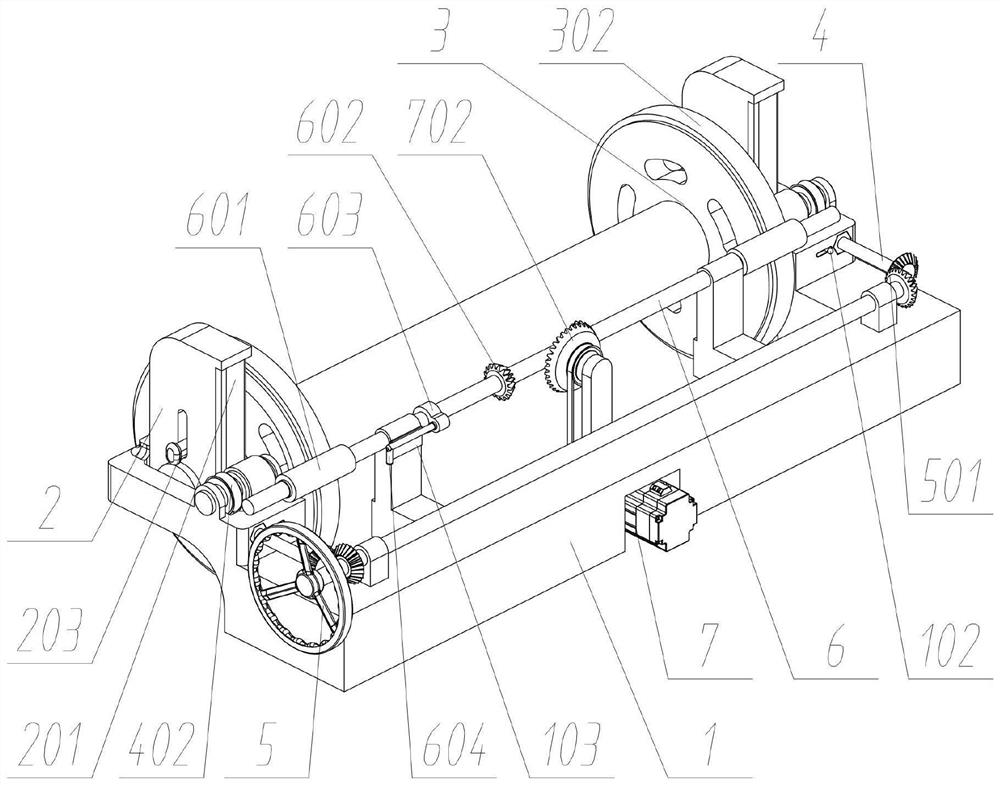

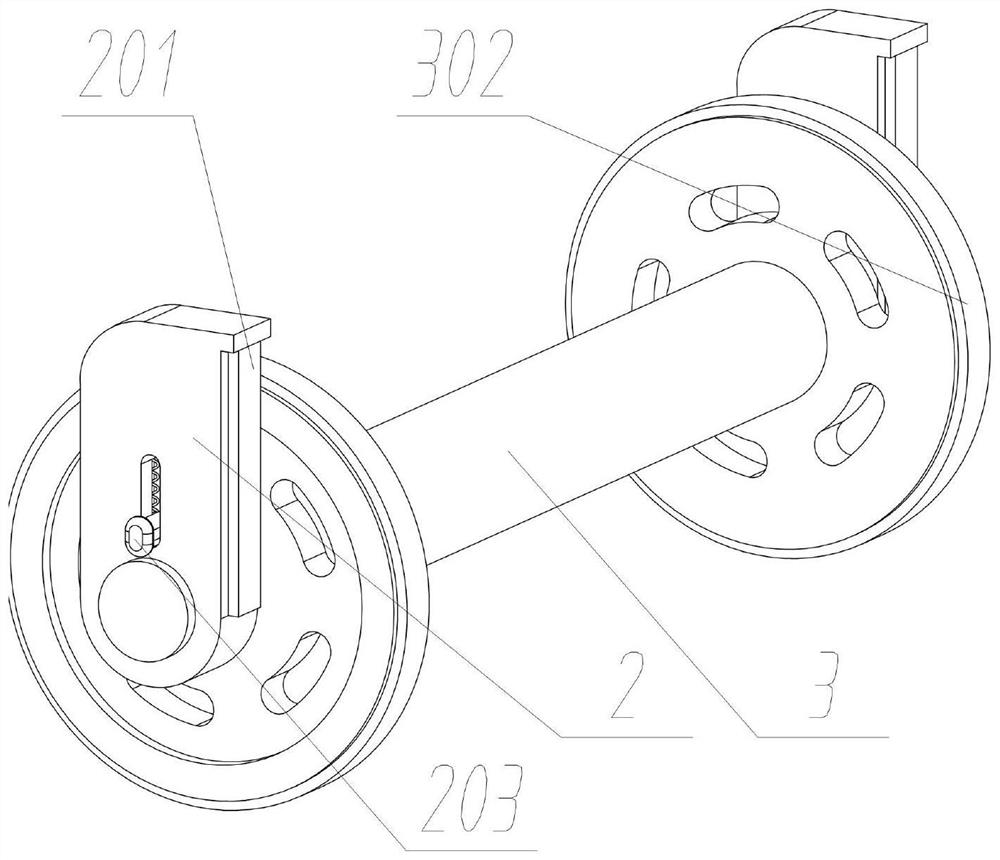

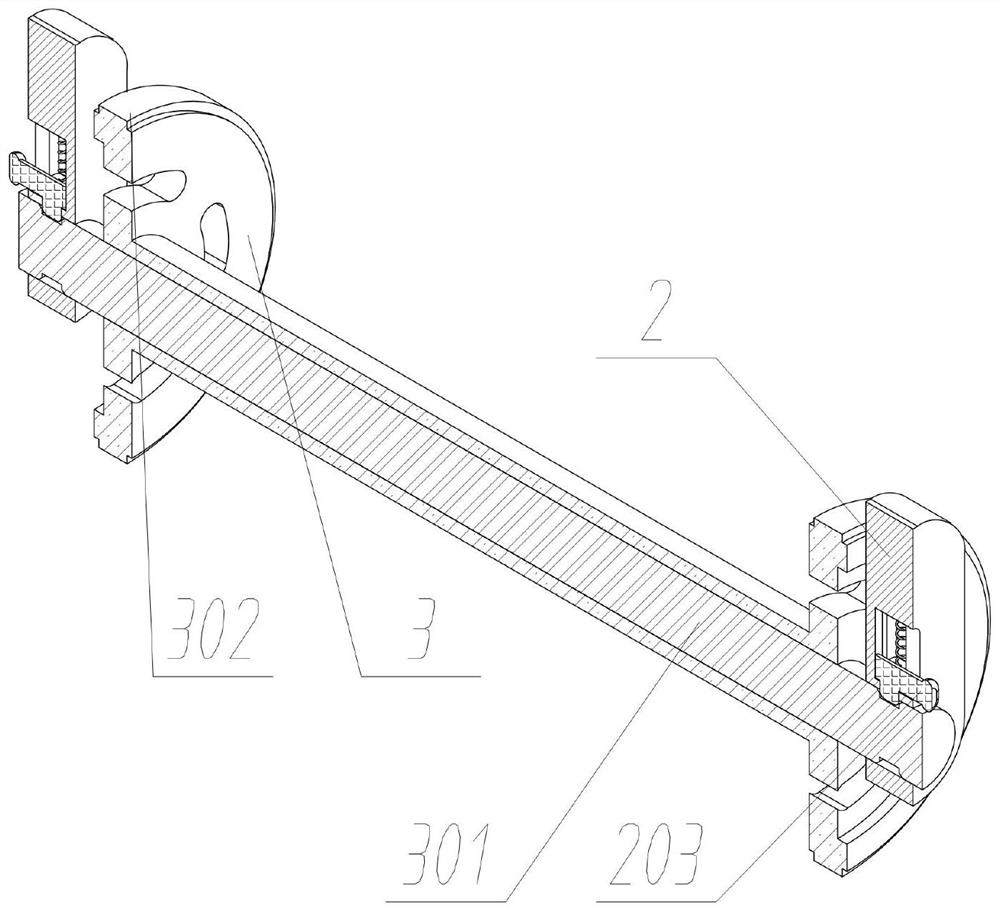

[0029] see Figure 1 to Figure 10 , an embodiment provided by the present invention: a textile machine with a yarn roll reversing drive device, including a yarn roll support 1; two sets of yarn roll lifters 2 are slidingly connected to the front of the yarn roll support 1, and each set of yarn rolls lifts A group of lifting rack racks 201 are fixedly connected to the rear of the frame 2; a group of yarn rolling rollers 3 are rotatably connected to the inside of the yarn rolling lifting frame 2, and a group of yarn rolling gears 302 are respectively fixedly connected to the outer ends of the yarn rolling rollers 3; The two sides of each set of elevator bevel gears 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com