Building mud head vehicle cleaning equipment

A technology for cleaning equipment and dump trucks, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of inability to clean mud blocks and low cleaning efficiency, and achieve the effects of reducing car washing costs, saving water and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

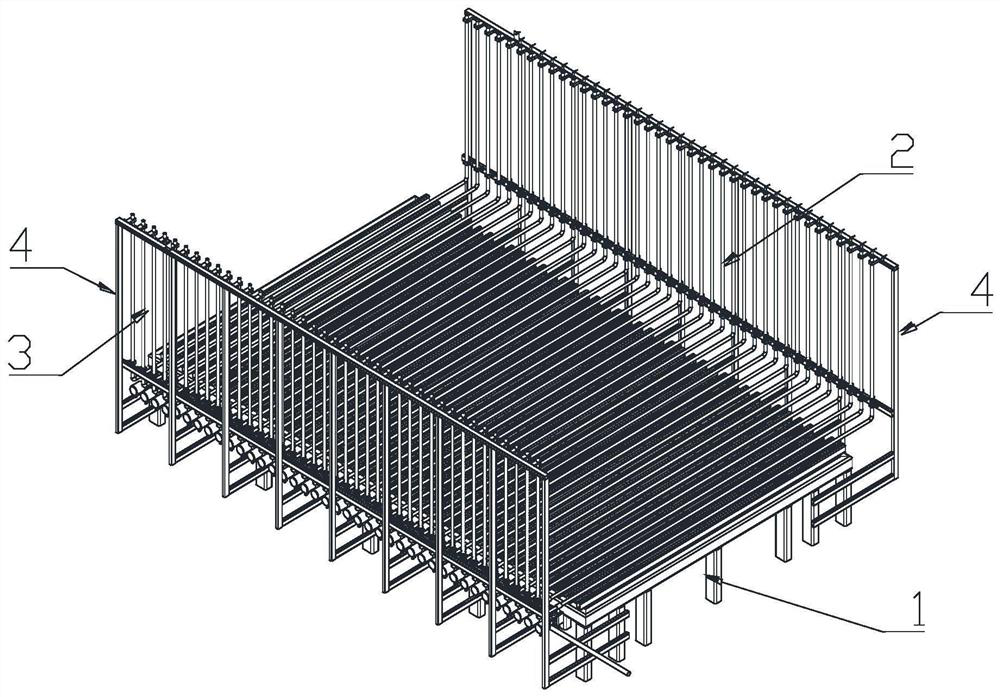

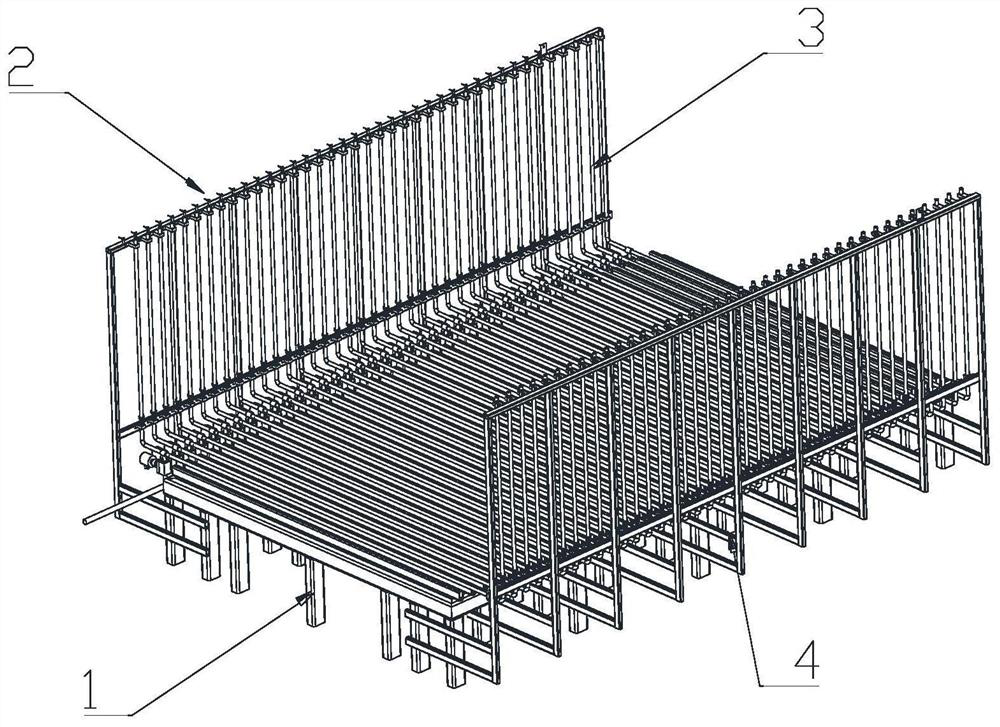

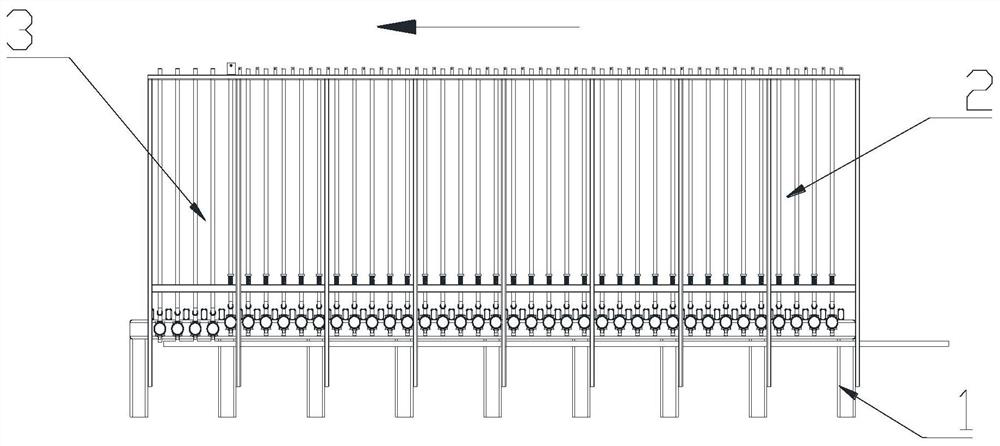

[0027] see Figure 1-Figure 7 , the construction dump truck cleaning equipment of the present invention includes a load-bearing frame 1, brackets 4 arranged on both sides of the load-bearing frame 1 and a first spray device 2 arranged on the bracket 4, wherein, the load-bearing frame 1 is provided with multiple Root load-bearing blocks 6, the plurality of load-bearing blocks 6 are arranged horizontally, and are arranged equidistantly along the length direction of the load-bearing frame 1; the first spray devices 2 are multiple groups, and multiple groups of first spray devices 2 Arranged sequentially along the length direction of the bracket 4, each group of first spraying devices 2 is located between two adjacent load-bearing blocks 6, including the spray bar 2-1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com