A surface cleaning device for auto parts

A surface cleaning device and auto parts technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problem of cleaning equipment damage on parts with protruding parts, irregular surface cleaning, and gaps in parts Difficult to clean and other problems to achieve the effect of ensuring ring cleaning and avoiding slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

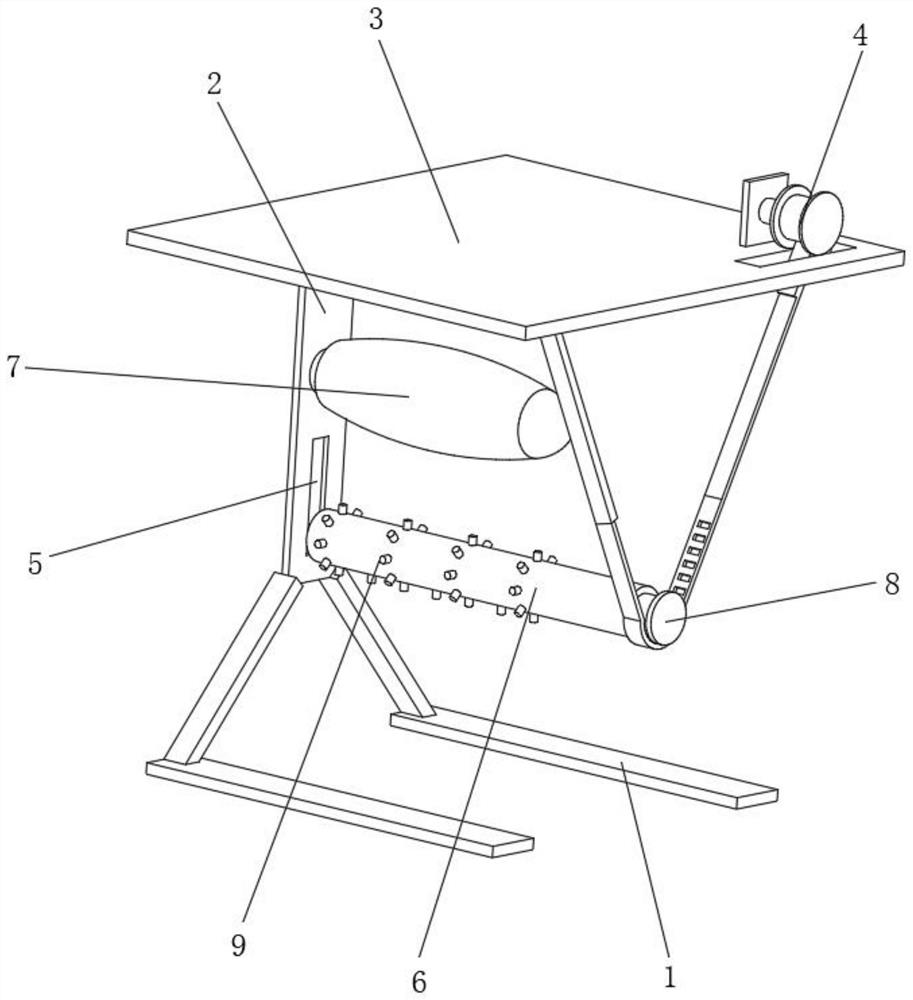

[0035] like figure 1 As shown, the present invention provides a technical solution: a surface cleaning device for auto parts, comprising a processing base 1, a restriction side frame 2 is fixedly connected to the top of the left side of the processing base 1, and a loading top plate is fixedly connected to the top of the restriction side frame 2 3. The top of the top plate 3 and the position close to the right side are fixedly connected with the drive winding wheel 4, and the right side of the side frame 2 and the position close to the bottom are fixedly connected with the moving chute 5, and the vertical position inside the moving chute 5 A driving wheel rod 6 is slidably connected, and a damping sleeve mechanism 7 is fixedly connected to the right side of the side frame 2 and close to the upper position. The damping sleeve mechanism 7 is parallel and corresponding to the driving wheel rod 6 , and the right side of the driving wheel rod 6 An adjustment drive mechanism 8 is fi...

Embodiment 2

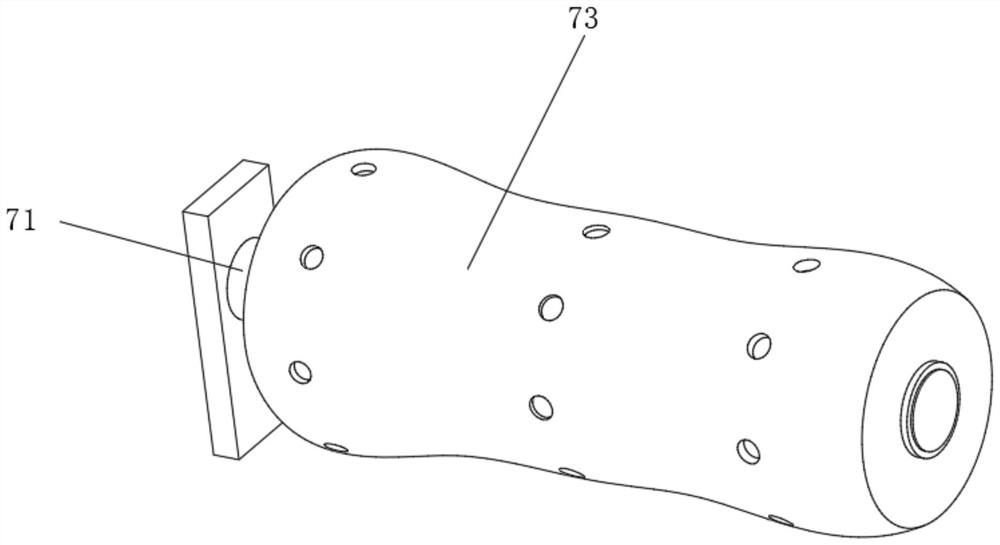

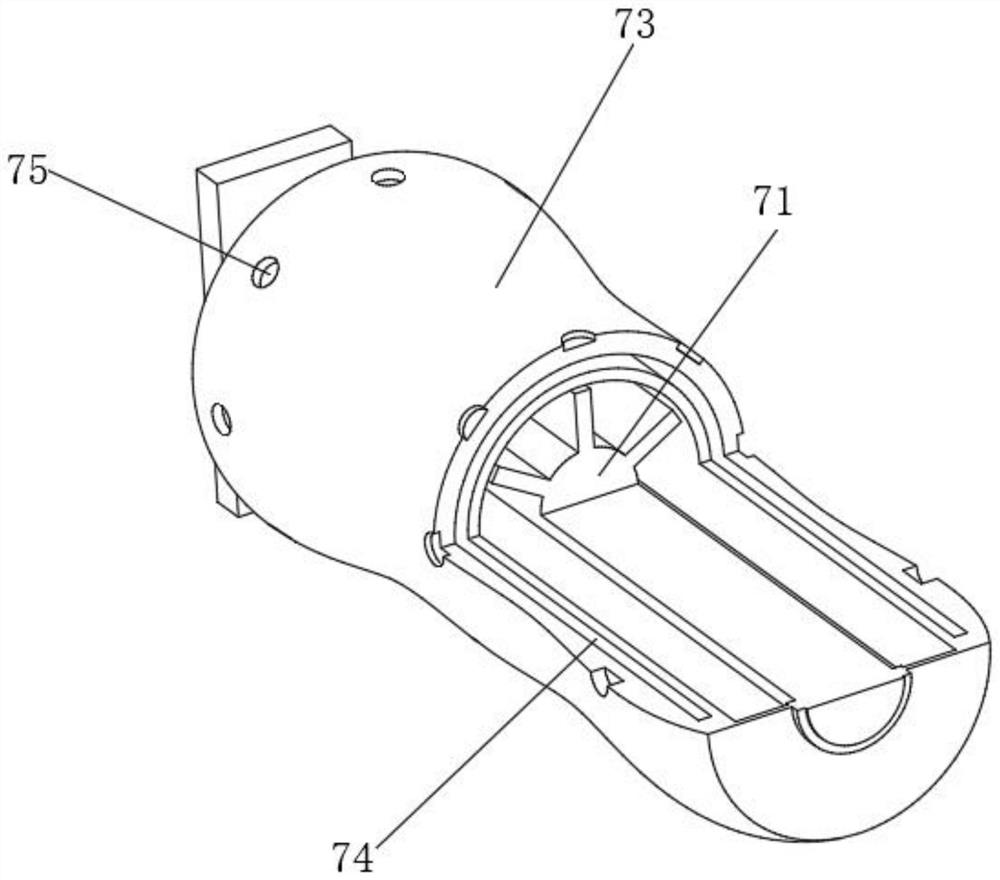

[0037] like Figure 2-4 As shown, on the basis of the first embodiment, the present invention provides a technical solution: a surface cleaning device for auto parts, the damping sleeve mechanism 7 includes a support connecting shaft 71, the left side of the support connecting shaft 71 and the limiting side frame 2 For fixed connection, a receiving inner groove 72 is sleeved on the outside of the support shaft 71 , and a rubber ring 73 is rotatably connected to the outside of the receiving inner groove 72 . The friction support strength of the contact position between the damping sleeve mechanism 7 and the tubular fitting is ensured, and at the same time, the matching groove 75 can be connected with the convex surface of the tubular fitting to further enhance the support friction.

[0038] A constant pressure air groove 74 is provided at the position between the lamination rubber ring 73 and the receiving inner groove 72 , and a matching connecting groove 75 is uniformly provi...

Embodiment 3

[0041] like Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a surface cleaning device for auto parts. It is fixedly connected with the driving wheel rod 6 , and the bottom surface of the anastomotic guide wheel 81 is rollingly connected with an elastic pulling belt 82 , and the end of the elastic pulling belt 82 away from the anastomotic guiding wheel 81 is wrapped around the outer surface of the driving winding wheel 4 .

[0042] One end of the elastic pulling belt 82 away from the driving rewinding wheel 4 is fixedly connected with a supporting pulling belt 83, and the supporting pulling belt 83 is fixedly connected with one side of the front of the top. The rotary drive for cleaning accessories is realized, and the ring cleaning of accessories is ensured.

[0043] Deformation resistance increasing grooves 84 are evenly and equally spaced on the inner surface of the elastic pulling belt 82 close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com