Self-locking mechanism and self-locking joint planer

A self-locking and rotating sleeve technology, used in medical science, surgery, etc., can solve the problems of low tool disassembly and assembly, complex installation and fixation structure, etc., achieve high surgical efficiency and accuracy, simplify installation and fixation structure, and improve disassembly and assembly. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

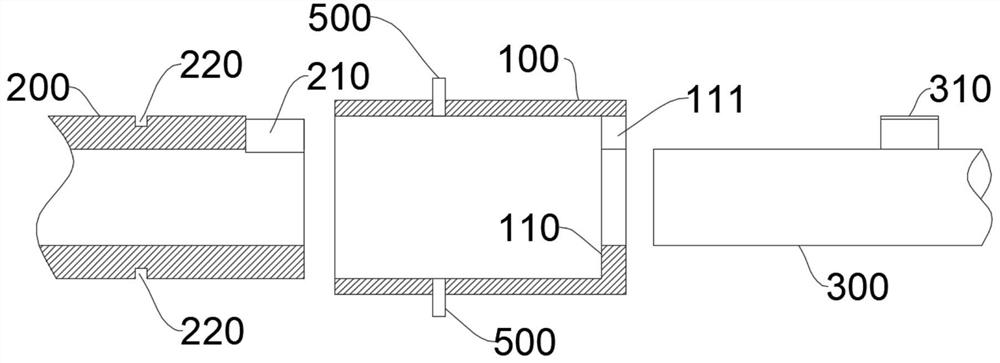

[0037] figure 1 It is a schematic exploded view of the structure of the self-locking mechanism provided by the first embodiment of the present invention; figure 2 An exploded cross-sectional view of the structure of the self-locking mechanism provided by the first embodiment of the present invention; image 3 It is a structural sectional view of the self-locking mechanism provided by the first embodiment of the present invention. Please refer to figure 1 , figure 2 , image 3 , the present embodiment provides a self-locking mechanism, which includes a rotating sleeve 100 , a connecting cylinder 200 and a connecting column 300 that are sequentially nested from outside to inside.

[0038] Wherein, the inner wall of the rotating sleeve 100 is provided with a limiting ring platform 110, and the first end face of the connecting cylinder 200 faces the limiting ring platform 110; the first end surface is provided with a first notch 210, and the limiting ring platform 110 is provi...

no. 2 example

[0049] Figure 4 It is a schematic exploded view of the structure of the self-locking mechanism provided by the second embodiment of the present invention; Figure 5 An exploded cross-sectional view of the structure of the self-locking mechanism provided by the second embodiment of the present invention; Image 6 It is a cross-sectional view of the relevant structure of the clockwork spring 420 in the self-locking mechanism provided by the second embodiment of the present invention. Please refer to Figure 4 , Figure 5 , Image 6 , the present embodiment provides a self-locking mechanism, which is substantially the same as the self-locking mechanism of the first embodiment, the difference between the two is that the elastic member in the self-locking mechanism of the present embodiment includes a clockwork spring 420; the clockwork spring 420 The inner end of the clockwork spring 420 is fixed on the connecting cylinder 200 , and the outer end of the clockwork spring 420 i...

no. 3 example

[0057] Figure 7 It is a sectional view of the structure of the self-locking joint planer provided by the third embodiment of the present invention. Please refer to Figure 7 , this embodiment provides a self-locking joint planer, which includes a handle 600, a cutter head 700 and the self-locking mechanism of any of the above embodiments, the connecting cylinder 200 is arranged on the handle 600, and the cutter head 700 is arranged on Connection column 300.

[0058] Further, as Figure 7 As shown, the axis of the cutter head 700 coincides with the axis of the connecting post 300 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap