Pork processing sausage stuffer

A sausage enema machine and pork technology, which is applied to sausage enema machines, meat processing equipment, processed meat, etc., can solve the problems of insufficient fixation of enema tubes, inconvenient pork processing, inconvenient cleaning, etc., to achieve firm fixation, labor saving, and convenience The effect of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

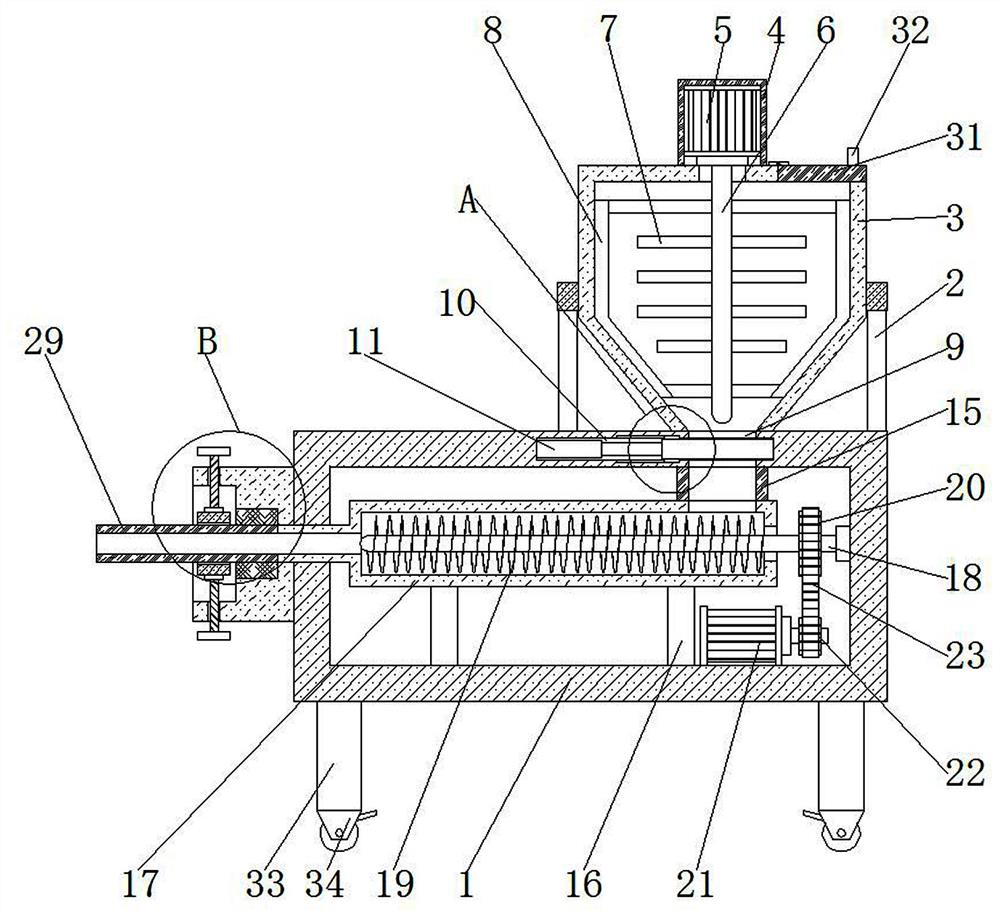

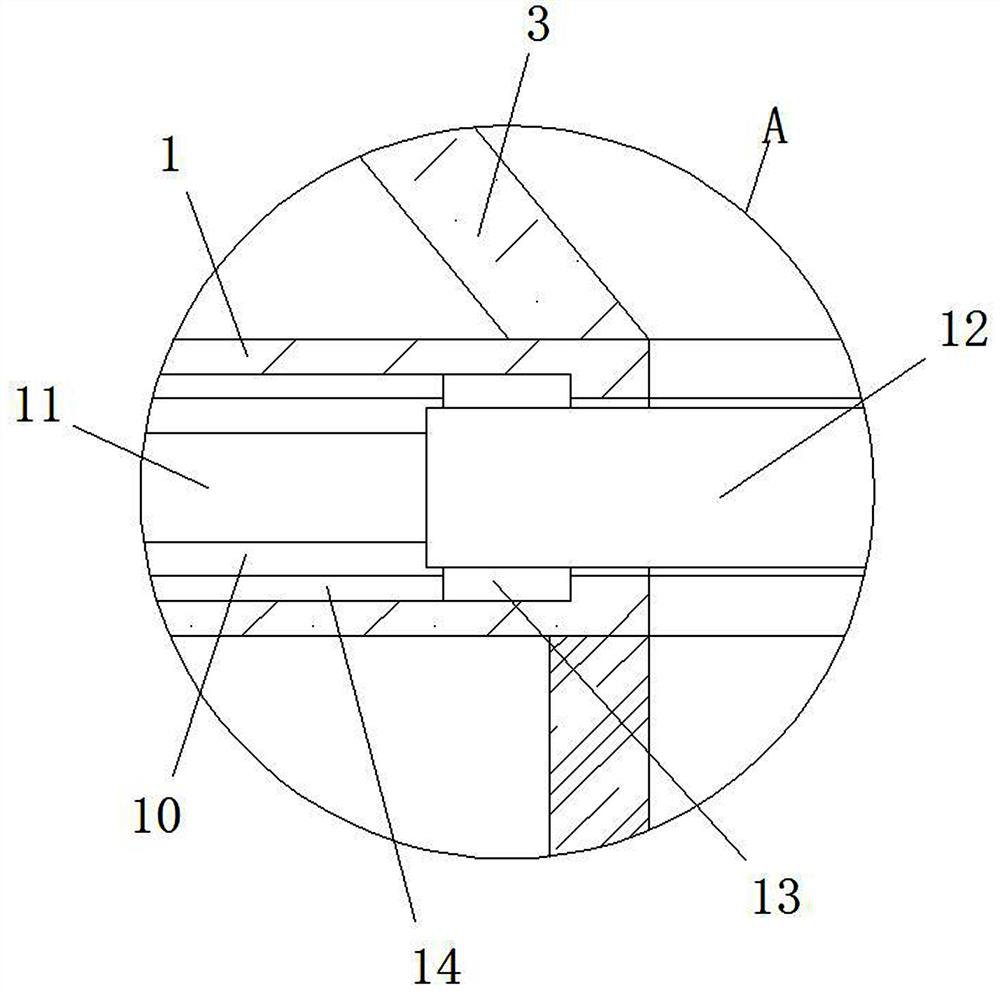

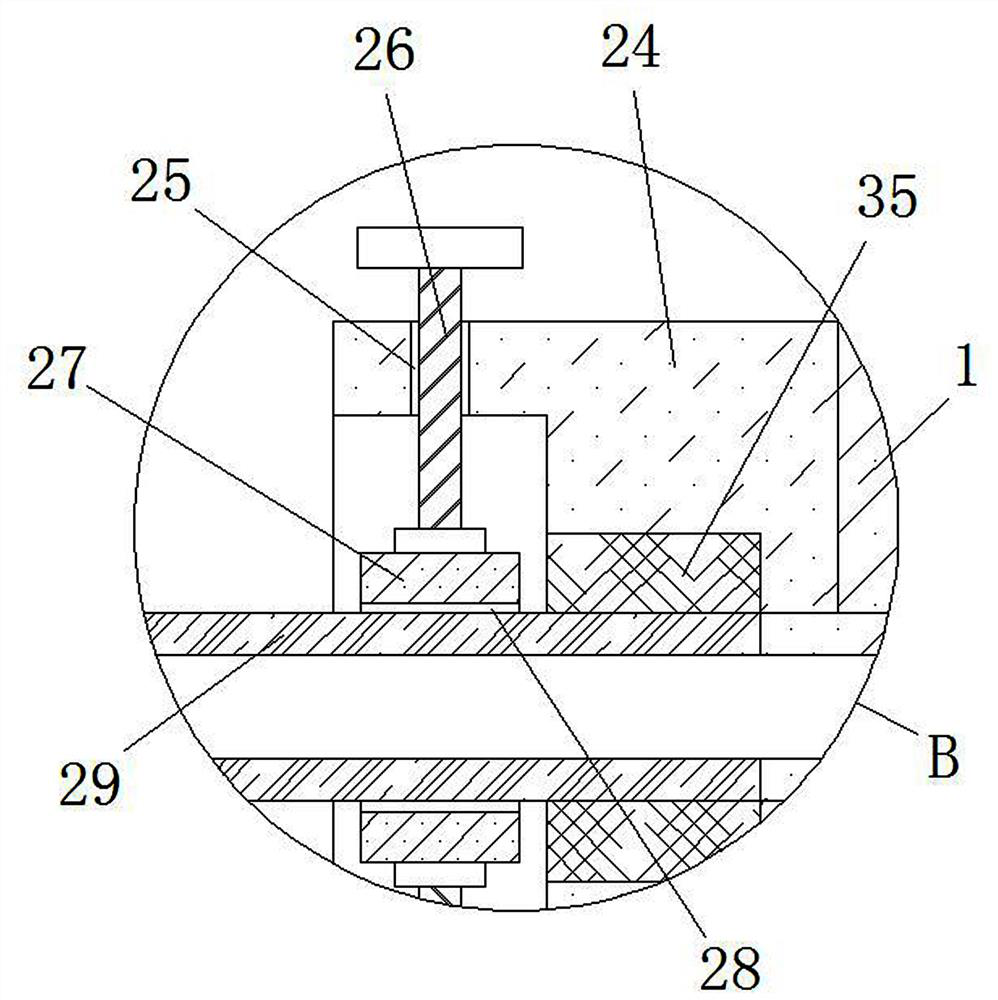

[0024] see Figure 1-5 , the present invention provides the following technical solutions: a pork sausage processing machine, comprising a housing 1, the top of the housing 1 is fixedly connected with a first support frame 2, the first support frame 2 is provided with a crushing shell 3, the crushing shell 3 The top is fixedly connected with a fixed shell 4, the interior of the fixed shell 4 is provided with a first motor 5, the output shaft of the first motor 5 is fixedly connected with a first rotating shaft 6, and the top of the crushing shell 3 is provided with a first round hole, and the second The inner wall of a round hole is fixedly connected with the first bearing, the first rotating shaft 6 is penetrated in the first bearing, the first rotating shaft 6 is provided with a crushing knife 7 and a scraper 8, and by setting the first motor 5, the first The motor 5 drives the pulverizer 7 to rotate, so that the pulverizer 7 stirs and pulverizes the pork, which is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com