Lawn trimmer for gardens

A lawn trimmer and gardening technology, applied in the field of garden machinery, can solve the problems of low pruning efficiency, large lawn area, and difficulty in keeping the lawn neat, etc., and achieve the effect of good pruning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

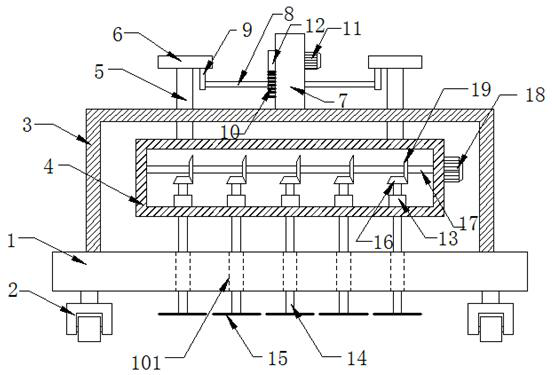

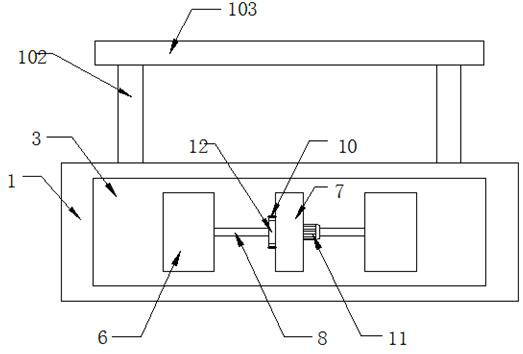

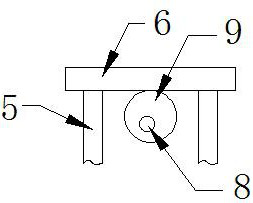

[0017] Such as Figure 1 ~ 3 As shown, the present invention discloses a garden lawn trimmer, including: base 1, universal wheel 2, hood 3, mounting tank 4, guide bar 5, fixed plate 6, fixed seat 7, rotating shaft 8, circular Packed 9, gear one 10, lift motor 11, gear two 12, bearing housing 13, vertical shaft 14, cutting tray 15, cone 1 16, horizontal axis 17, cutting motor 18, cone gear 2 19, the base 1 A universal wheel 2 is installed on the four top angles on the lower end surface, and a hood 3 is fixed at the end surface of the base 1, and the lower opening of the hood 3 is provided, and the interior level of the hood 3 is provided with a mount. Box 4, the four top angles on the upper surface of the mounting tank 4 are vertically secured to a guide bar 5, and the guide bar 5 passes through the top wall of the hood 3 and slides together, two of the left side. The top portion of the guide rod 5 and the top of the right two guide rods 5 are fixed to the upper end surface of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com