Small seed dual-purpose cone-embedded double-circular-truncated-cone annular air distribution mechanism

A gas distribution mechanism and dual-purpose technology, which is applied to the parts of the seeder, can solve the problems of unreasonable structure, affecting the consistency of seed discharge, air flow loss, etc., and achieve the goals of reducing loss, good consistency, and reducing air flow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

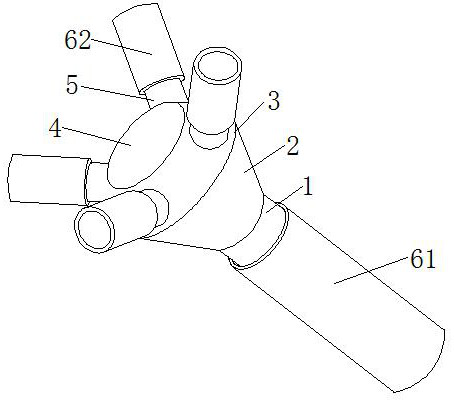

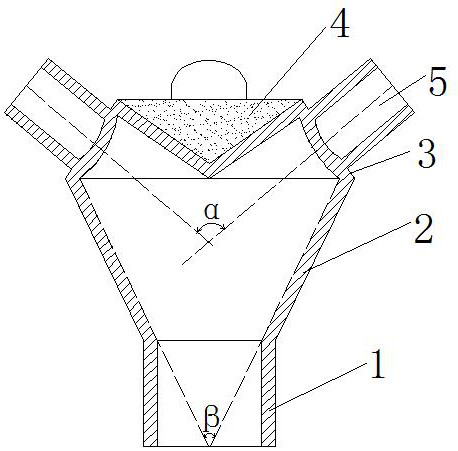

[0024] Such as Figure 1-3 As shown in , a small-seed double-purpose embedded cone-shaped double-circle ring-type air distribution mechanism includes an air flow access pipe 1, an air distribution mechanism housing and an air distribution pipe 5. The air distribution mechanism housing includes a high There are three parts: the circular platform 2, the short circular platform 3 and the inverted cone 4. The small circular platform side of the high circular platform 2 coincides with one end of the cylindrical airflow inlet pipe 1, and the large circular platform side of the high circular platform 2 and the short circular platform 3 The large circular platform side overlaps and penetrates, and the airflow access pipe 1, the high circular platform tube 2 and the short circular platform tube 3 form a special-shaped through-tube body with coincident axes; the small circular platform side of the short circular platform tube 3 is connected to the round surface of the inverted cone 4, an...

Embodiment 2

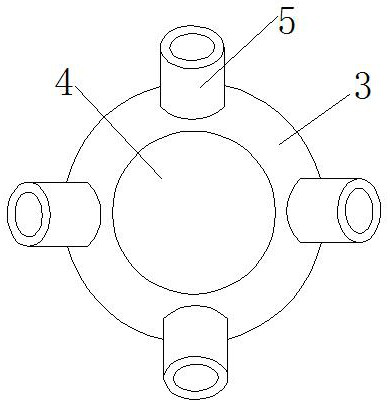

[0036] On the basis of Example 1, such as Figure 4 As shown, the number of air distribution pipes 5 is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com