Magnetic core overturning and conveying system for large transformer

A conveying system and transformer technology, which can be used in inductor/transformer/magnet manufacturing, magnetic core manufacturing, conveyor objects, etc., and can solve the problems of low efficiency and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

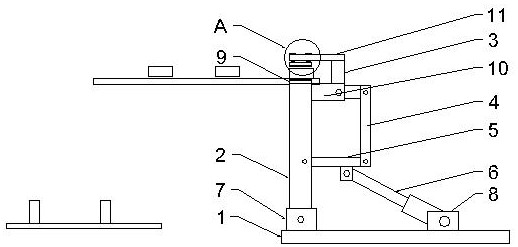

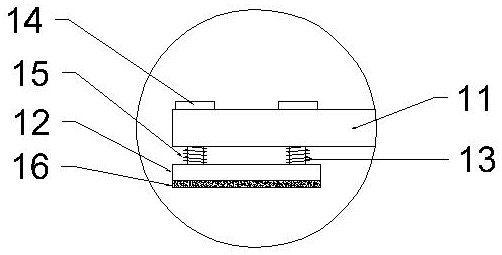

[0011] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , a large-scale transformer magnetic core flip conveying system described in this embodiment includes a base 1, which also includes a swing arm 2, a first hinge arm 3, a second hinge arm 4, a third hinge arm 5, and a push cylinder 6 , wherein a swing arm hinge seat 7 is installed on the top of one end of the base 1, a cylinder hinge seat 8 is installed on the top of the other end of the base 1, the bottom of the swing arm 2 is movably hinged on the swing arm hinge seat 7, and a lower splint 9 is installed on the top of the swing arm 2 The upper part of the swing arm 2 located on one side of the cylinder hinge seat 8 is equipped with a hinge arm hinge seat 10, and the middle part of the first hinge arm 3 is movably hinged on the hinge arm hinge seat 10. The first hinge arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com