Infrared thermal image analysis method for nondestructive testing of defects of composite material

A technology of non-destructive testing and analysis methods, applied in the direction of material defect testing, radiation pyrometry, measuring devices, etc., which can solve the problems of limited defect information extraction, incomplete defect detection, and non-centralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

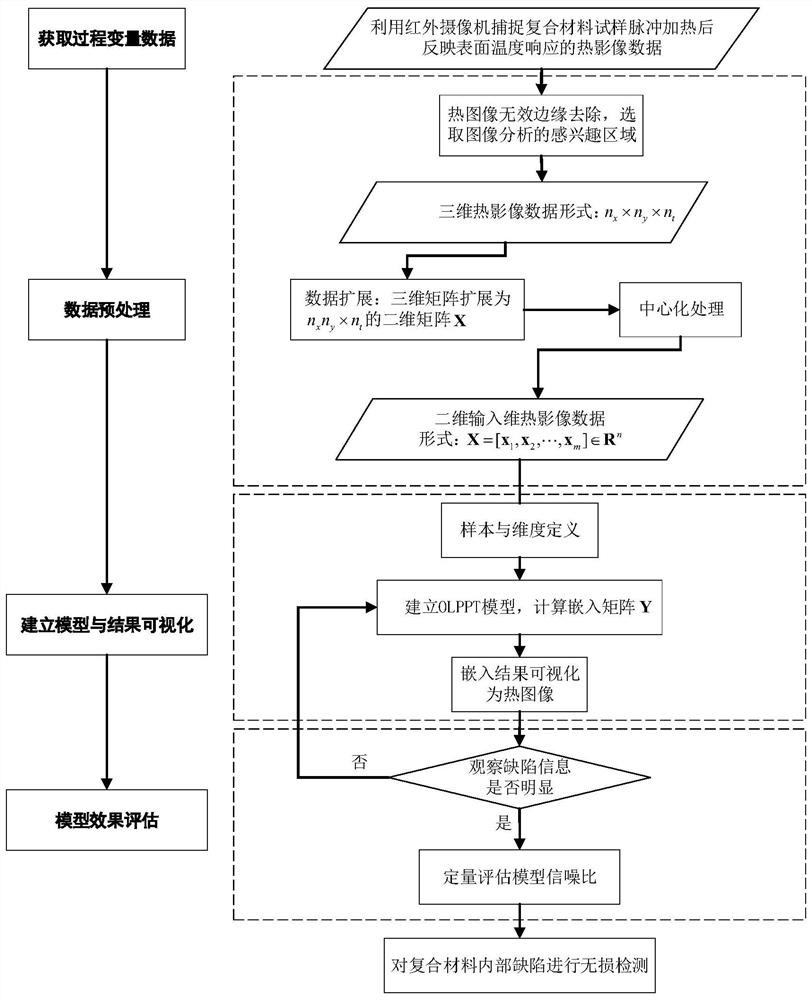

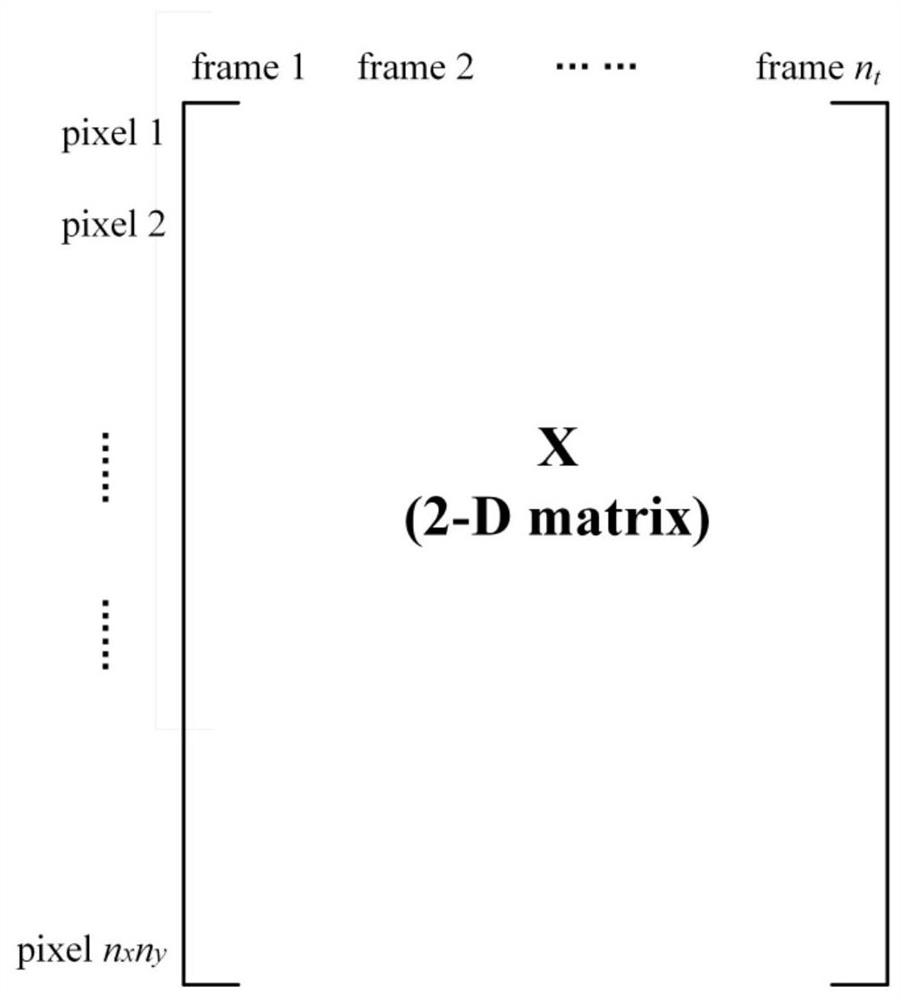

[0067] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

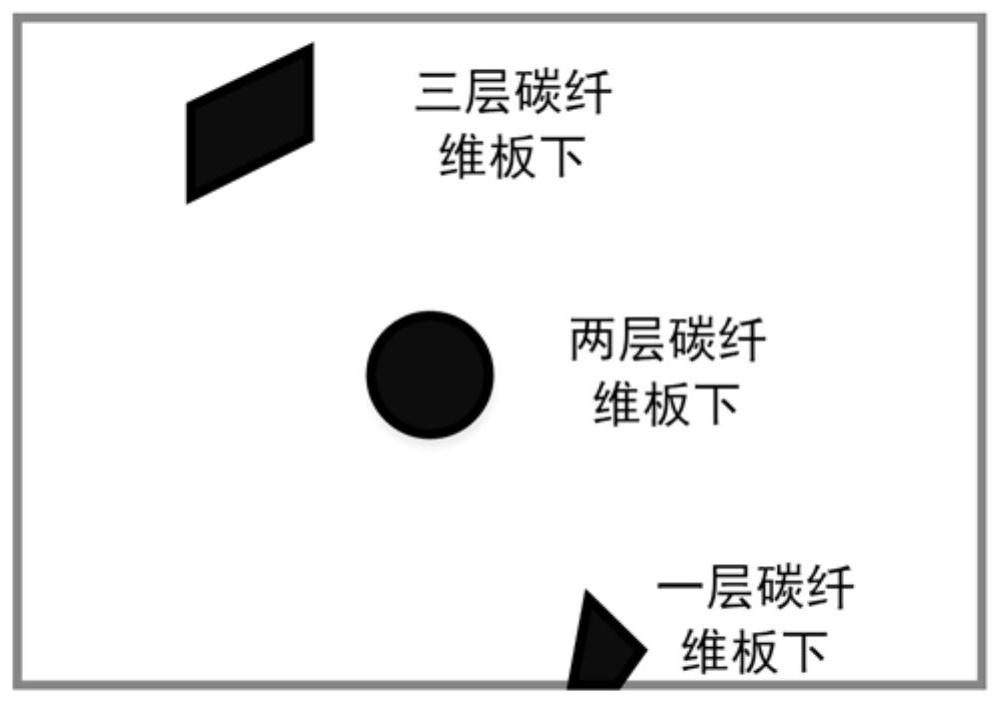

[0068] In order to effectively prove the effect of the OLPPT model proposed by the present invention, an artificially manufactured carbon fiber reinforced polymer (CFRP) sample is used as a defect detection object.

[0069] CFRP Defect Specimen Fabrication Process: In this CFRP specimen fabrication process, three flat-arranged Teflon strips with different shapes are inserted into the carbon fiber sheet during the step of performing lamination, purposefully producing different positions, Defects in shape and depth. The shallowest defect, located in the lower right quadrant, was created by inserting trapezoidal Teflon strips under the single-ply carbon fiber sheet to a depth of approximately 0.05 cm. In the middle part of the specimen, there is a circular defect under the two layers of carbon fiber plates, and its depth is about 0.10 cm. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com