Y-direction four-guide-rail structure

A technology of four guide rails and guide rails, applied in the direction of removing smoke and dust, bearings, bearings of linear motion, etc., can solve the problems affecting the installation position of operating equipment, the stability of the operation range, and the inconvenience of installation and use of four guide rails, so as to reduce costs and maintain Difficulty, save fixed space, ensure neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

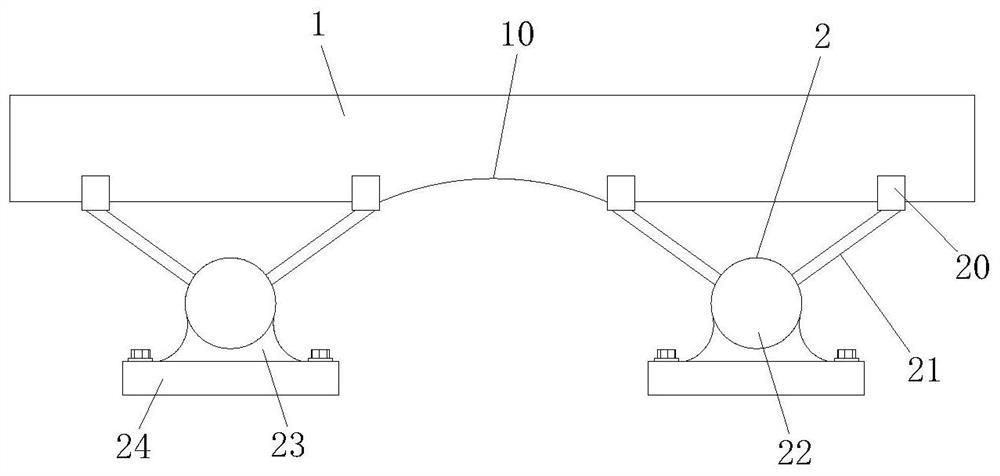

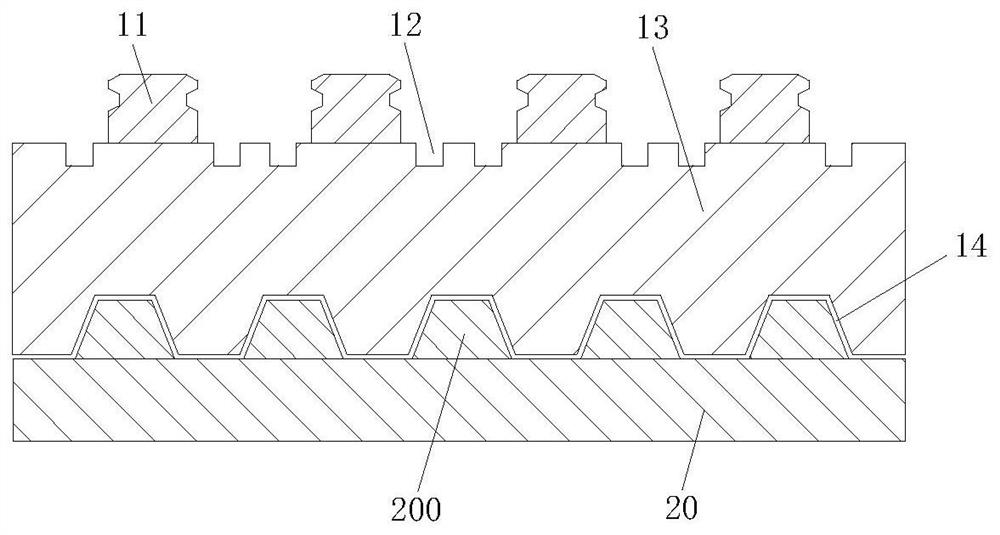

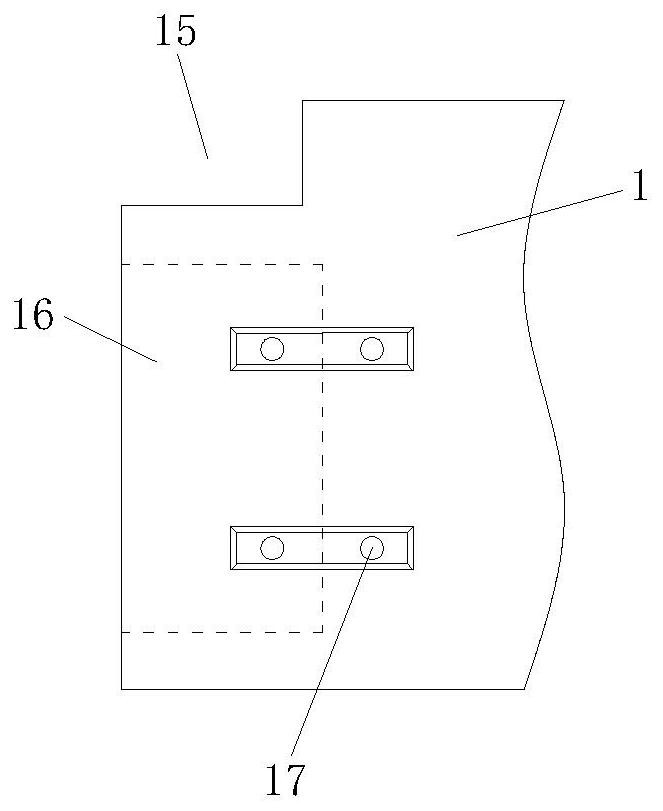

[0029] Example 1, please refer to Figure 1~2 And 5-6, a Y-direction four-way guide rail structure, including a guide rail body 1, a fixing frame 2 supporting the guide rail body 1, and a dust-proof dust sweeping mechanism 3 on the guide rail body 1;

[0030] Described guide rail body 1 comprises guide rail bar 11 and support base 13, and the quantity of guide rail bar 11 is four and is all fixed on the support base 13 by bolt, and the left and right sides positions of guide rail bar 11 on the support base 13 are preset with strips. Shaped grooves 12 and strip grooves 12 are used to temporarily store dust and other foreign objects to avoid affecting normal travel when the guide rail is in use. The dust in the strip grooves is cleaned regularly every day. The upper bottom of the support seat 13 is evenly preset with trapezoidal grooves 14 , an arched groove 10 is preset between the fixed frames 2 adjacent to the bottom of the guide rail body 1;

[0031] The fixed frame 2 inclu...

Embodiment 2

[0034] Example 2, please refer to Figure 1~6 , a Y-direction four guide rail structure, including a guide rail body 1, a fixing frame 2 supporting the guide rail body 1, and a dust sweeping mechanism 3 on the guide rail body 1 for dust prevention;

[0035] Described guide rail body 1 comprises guide rail bar 11 and support base 13, and the quantity of guide rail bar 11 is four and is all fixed on the support base 13 by bolt, and the left and right sides positions of guide rail bar 11 on the support base 13 are preset with strips. Shaped grooves 12 and strip grooves 12 are used to temporarily store dust and other foreign objects to avoid affecting normal travel when the guide rail is in use. The dust in the strip grooves is cleaned regularly every day. The upper bottom of the support seat 13 is evenly preset with trapezoidal grooves 14 , an arched groove 10 is preset between the fixed frames 2 adjacent to the bottom of the guide rail body 1;

[0036]The top position of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com