Automatic cleaning device for highway guardrail

A technology for automatic cleaning and highway guardrails, applied in road cleaning, cleaning methods, construction, etc., can solve problems such as low work efficiency and low safety, and achieve the effects of improving work efficiency, avoiding accidents, and facilitating the direction of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] A highway guardrail automatic cleaning device, such as figure 1 and figure 2 As shown, it includes a support plate 1, a push handle 101, a wheel 2, a movable assembly 3 and a cleaning assembly 4, a push handle 101 is provided on the rear side of the top of the support plate 1, a movable assembly 3 is provided on the front side of the top of the support plate 1, and the support plate Wheels 2 are provided on the rear side of the bottom and a part of the movable assembly 3, and a cleaning assembly 4 is provided in the middle of the top of the support plate 1.

[0085] When people need to clean the guardrail, push the push handle 101 forward, under the action of the wheels 2, the whole device can be pushed to the side of the guardrail, the direction of advancement can be controlled by the movable component 3, and then the cleaning component 4 cleans the guardrail .

Embodiment 2

[0087] On the basis of Example 1, such as image 3 , Figure 4 and Figure 5 As shown, the movable assembly 3 includes a first support frame 301, a first rotating block 302, a movable rod 303 and a second rotating block 304. The first rotating block 302 is arranged in the middle of the part, and the left and right sides of the first supporting frame 301 are rotatingly provided with a second rotating block 304. The bottom of the second rotating block 304 is connected with wheels 2, and the first supporting frame 301 The front sliding type is provided with a movable rod 303, and the movable rod 303 is connected with the first rotating block 302 and the second rotating block 304.

[0088] When people need to clean the guardrail, push the push handle 101 forward, under the action of the wheels 2, the whole device can be pushed to the side of the guardrail, and the second rotating block 304 is driven to rotate by the first support frame 301 and the movable rod 303, The second ro...

Embodiment 3

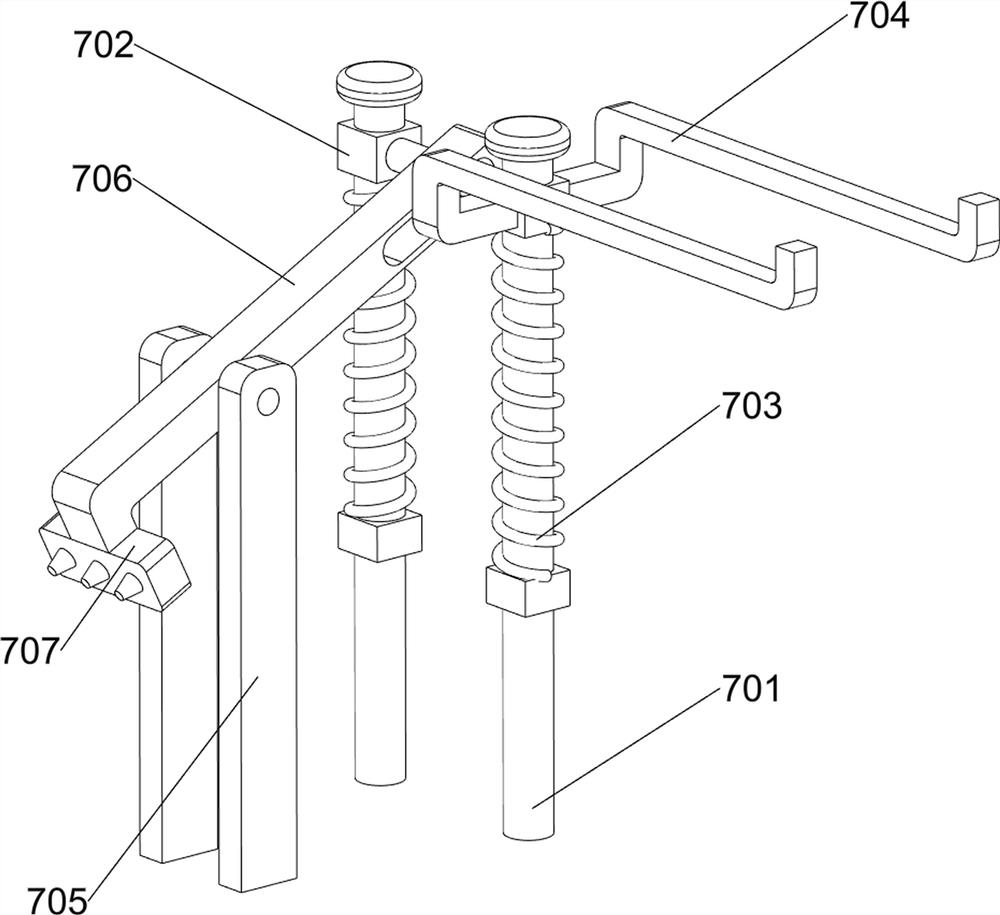

[0096] On the basis of Example 2, such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a sprinkler assembly 7 is also included, and the sprinkler assembly 7 includes a first guide rod 701, a first slider 702, a first spring 703, a pressing rod 704, a third support block 705, a first rotating rod 706 and a spray head 707 , the middle of the front side of the top of the support plate 1 is symmetrically provided with a first guide rod 701, the first slide block 702 is slidably arranged between the top of the first guide rod 701, and the bottom of the first guide rod 701 is connected to the bottom of the first slide block 702. A first spring 703 is arranged between them, and the first spring 703 is set on the outside of the first guide rod 701 on the same side. The left and right rear parts of the first slider 702 are symmetrically provided with pressing rods 704, and the pressing rods 704 and the first piston 505, the right part of the top front side of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com