Environment-friendly easily-degradable plastic film bag and production method

A technology for plastic film bags and production methods, which are applied in chemical instruments and methods, sacks, bag making operations, etc., can solve the problem that the structural strength and degradability of composite film bags cannot be combined, have no practicability, and have a small scope of application, etc. problem, to achieve the effect of complete photodegradability, complete biodegradability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

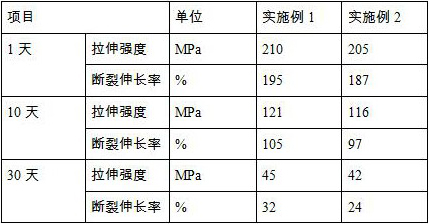

Embodiment 1

[0038] This embodiment provides a technical solution: an environment-friendly easily degradable plastic film bag and its production method. The plastic film bag includes an inner film and an outer mold.

[0039] The inner film includes the following raw materials by weight: 50 parts of PVC, 25 parts of plasticizer, 5 parts of deionized water, and 2 parts of photoinitiator.

[0040] The outer film comprises the following raw materials by weight: 50 parts of flax fiber, 30 parts of corn starch, 8 parts of plasticizer, and 8 parts of deionized water.

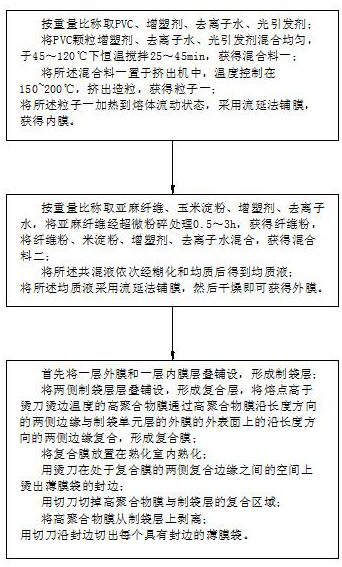

[0041] see figure 1 , and then prepare the film bag as follows:

[0042] S1. Weigh PVC, plasticizer, deionized water, and photoinitiator by weight.

[0043] Mix the PVC granule plasticizer, deionized water, and photoinitiator evenly, and stir at a constant temperature of 45-120° C. for 25-45 minutes to obtain a mixture one.

[0044] Put the mixture 1 in the extruder, control the temperature at 150-200°C, extrude and granulate to...

Embodiment 2

[0057] This embodiment provides a technical solution: an environment-friendly easily degradable plastic film bag and its production method. The plastic film bag includes an inner film and an outer mold.

[0058] The inner film includes the following raw materials by weight: 55 parts of PVC, 20 parts of plasticizer, 7 parts of deionized water, and 4 parts of photoinitiator.

[0059] The outer film comprises the following raw materials by weight: 40 parts of flax fiber, 25 parts of corn starch, 7 parts of plasticizer, and 7 parts of deionized water.

[0060] see figure 1 , and then prepare the film bag as follows:

[0061] S1. Weigh PVC, plasticizer, deionized water, and photoinitiator by weight.

[0062] Mix the PVC granule plasticizer, deionized water, and photoinitiator evenly, and stir at a constant temperature of 45-120° C. for 25-45 minutes to obtain a mixture one.

[0063] Put the mixture 1 in the extruder, control the temperature at 150-200°C, extrude and granulate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com