Three-layer composite fiber material and preparation method, device and application thereof

A fiber material and composite fiber technology, which is applied in the field of three-layer composite fiber material and its preparation, can solve the problems of poor deformation resistance, reduced contact area, poor three-dimensional retention, etc., and achieves good resilience and deformation resistance, and reduces contact. Area, good rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

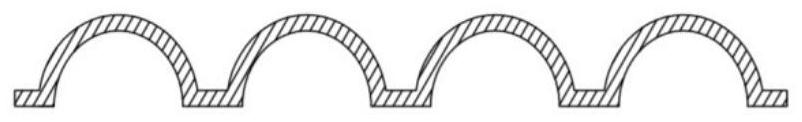

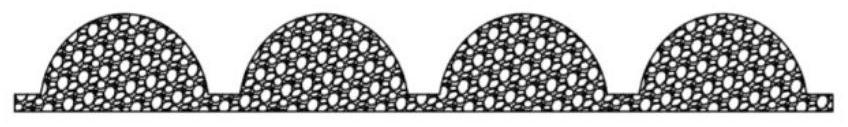

[0054] The three-layer composite fiber material provided by the present invention has a structure such as Figure 4 and 5 shown. Figure 4 is the front view of the three-layer composite fiber material, Figure 5 The cross-sectional view of the three-layer composite fiber material; Figure 5 shown Figure 4 The cross-sectional view at F-F, including the bottom layer 3 and the surface layer 1, and the filling layer 2 filled between the bottom layer 3 and the surface layer 1; the bottom layer 3, the filling layer 2 and the surface layer 1 are three-layer compounded through the bonding part 4, bonding The part 4 is distributed in the concave part 6; the surface layer 1 includes a 3D convex part 7 and a concave part 6; the surface layer and the filling layer have openings 5 in the 3D convex part, and the opening 5 is represented as a hole through the surface layer on the surface layer , the opening 5 is shown as a non-through hole on the filling layer, that is, the opening 5 ...

Embodiment 2

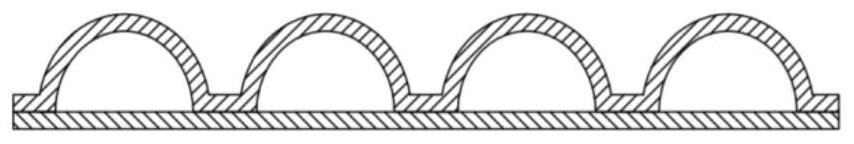

[0092] Such as Figure 12 front view shown and Figure 13 and Figure 14The section shown is an example, the surface layer is made of pure cotton spunlace cloth 40gsm, the filling layer is made of elastic fluffy air-through non-woven fabric 35gsm and the bottom layer is made of air-through non-woven fabric 16gsm, using 3D raised parts of different shapes, sizes and heights , the depth, size and number of openings at different positions to achieve and meet the diverse customer product needs; Figure 13 The cross-sectional view of shows the 3D convex parts with different heights, and the openings are all through-holes through the three-layer fiber material; Figure 14 The cross-sectional view of shows the 3D convex parts with different heights. The openings shown are from left to right the through holes penetrating through the three layers of fiber materials, the large openings penetrating the non-penetrating filling layer of the surface layer, and the openings penetrating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com