A method of using a cement stone curing device

A cement stone and curing kettle technology, which is applied in the field of oil and gas well cementing, can solve the problems of reduced internal structural strength performance, unrepresentable cement stone, and long time spent on curing kettles, so as to improve efficiency, simplify structure, reduce manufacturing difficulty and The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

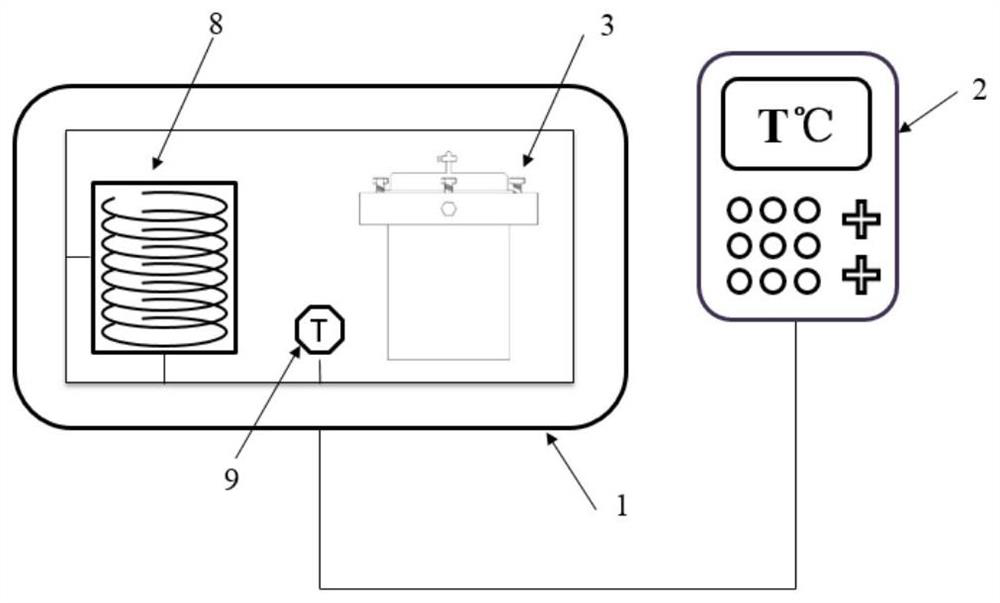

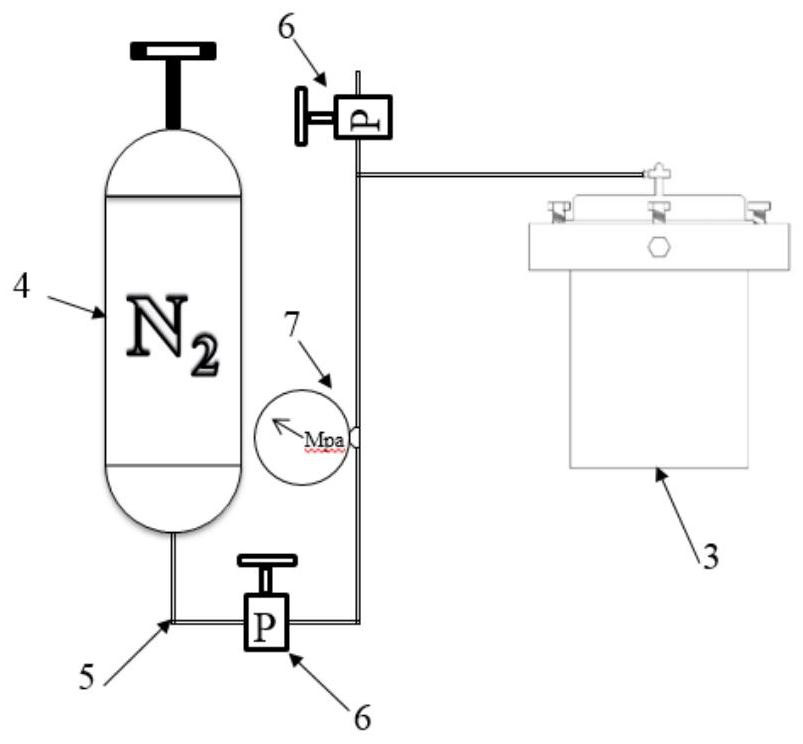

[0056] Such as figure 1 As shown, a cement stone curing device includes: a heating device and a pressurizing device;

[0057] The heating device includes: a constant temperature heating box 1, a temperature controller 2, and a curing kettle 3;

[0058] The inner or outer wall of the constant temperature heating box 1 is provided with a resistance heating wire 8 , and it can also be arranged on the outer wall of the constant temperature heating box 1 to realize heating of the whole box body. Simultaneously, the front of the constant temperature heating box 1 is provided with a box door, and the curing kettles 3 of different sizes can be put into the box for maintenance by opening the box door.

[0059] The outside of the constant temperature heating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com