Universal jig for detecting thickness of lens

A lens thickness and jig technology, applied in the mechanical field, can solve the problems of low application value and difficult to work with thickness measurement, and achieve the effect of saving reading time, reducing scratches on the workpiece surface, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the key problem of measuring the above-mentioned medium thickness, the inventor of this case conducted careful design and research, and designed a universal jig for detecting the thickness of the lens.

[0026] Embodiments are described below in conjunction with the accompanying drawings of the description

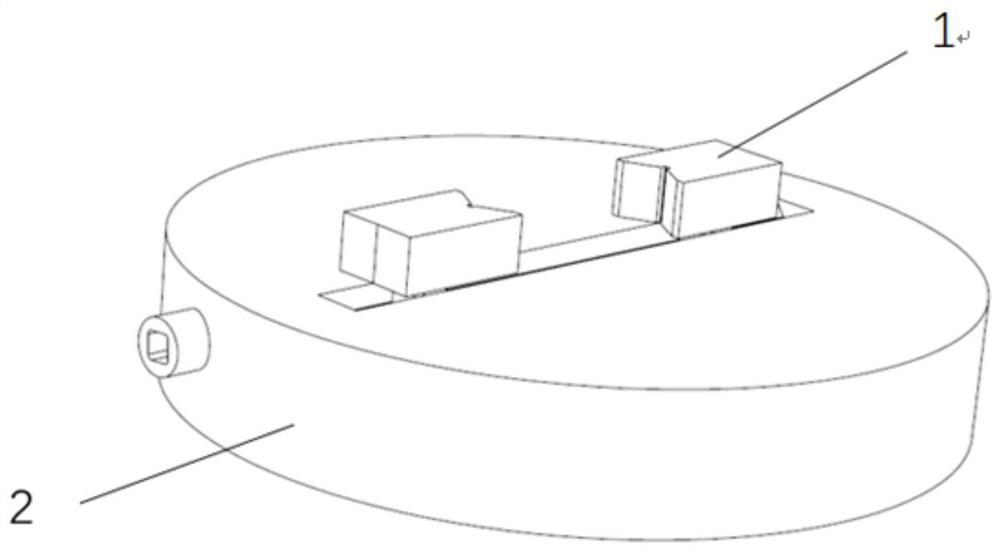

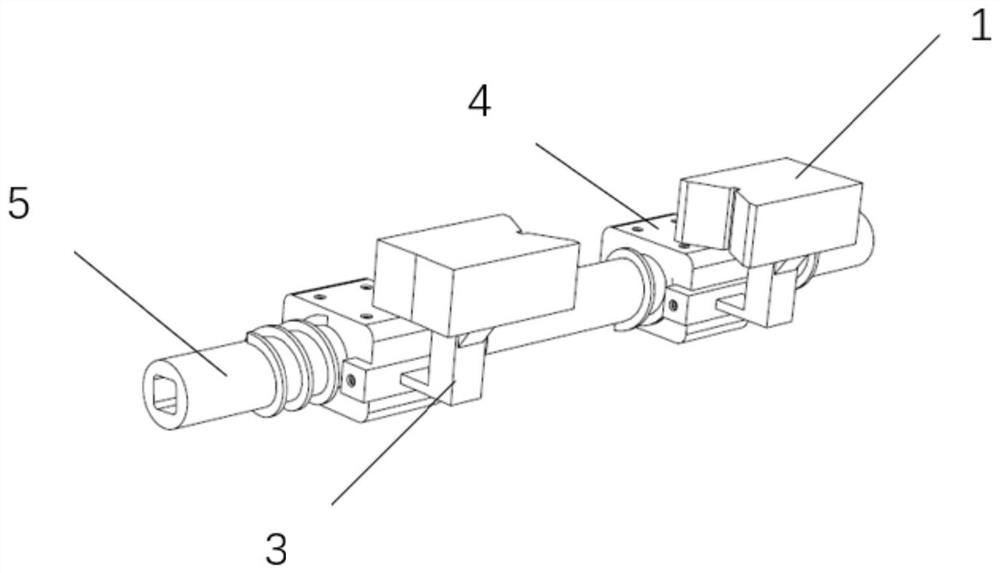

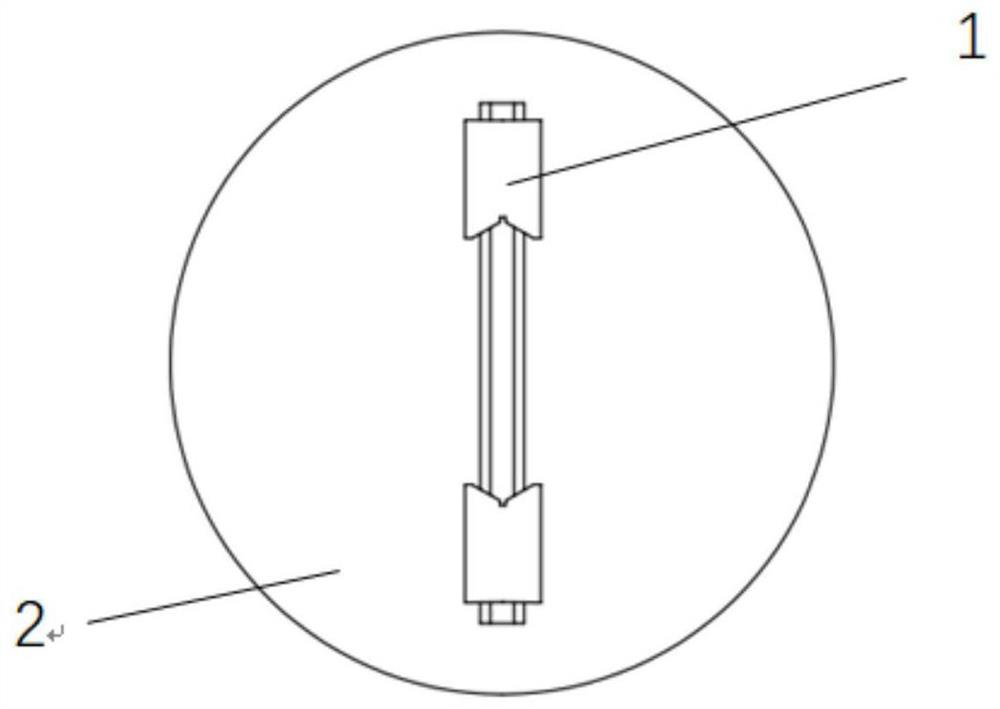

[0027] Such as figure 1 As shown, the universal fixture includes a fixture shell 2, a V-shaped block 1, a guide slider 4, a screw nut seat 3, a double-threaded screw 5, a V-shaped block 1, a guide slider 4, a screw nut seat 3, and a double-threaded screw. The threaded screw rod 5 forms the transmission part.

[0028] The jig shell 2 is a cylindrical shell, and its inner space is used to place internal transmission components, and its upper surface has a dovetail chute for placing the guide slider 4 . The lower surface is hollowed out, and the jig shell 2 is semi-enclosed to cover most of the parts below, which can effectively avoid dust and debri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com