Controllable converter electric-arc furnace

A converter and arc furnace technology, which is applied to electrical components, conversion devices for converting AC power input into AC power output and output power, etc., can solve the problem of high operating costs of electric arc furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

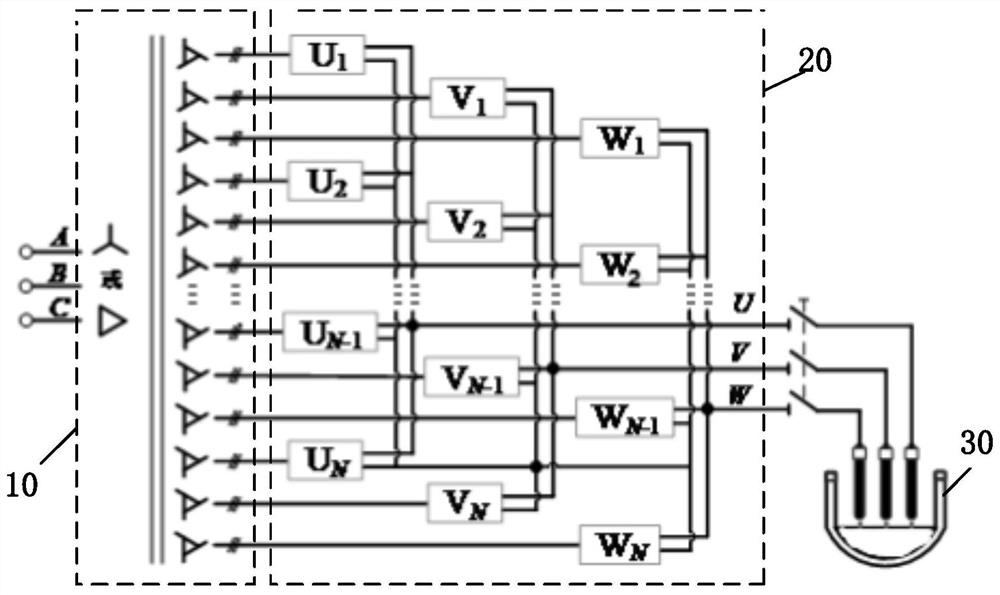

[0087] optional, please refer to figure 2 , as a specific implementation of the controllable variable-flow electric arc furnace provided in the embodiment of the present invention, the controllable variable-flow electric arc furnace also includes:

[0088] Multiple off-load disconnect switches.

[0089] The no-load isolating switch is connected between the output end of the three-phase converter and the power input end of the AC electric arc furnace.

[0090] In this embodiment, multiple off-load isolating switches are added to the controllable variable current electric arc furnace. In specific implementation, an unloaded isolating switch can be set at each output end of the three-phase converter, or an unloaded isolating switch can be set at the output end of each rectification and inverter unit in the three-phase converter , is not limited here.

[0091] In this embodiment, the fault protection of the controllable variable current electric arc furnace can be better reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com