Device for loosening and tightening railway steel rail fastener bolts

An elastic device and bolt technology, applied in the field of railway engineering machinery, can solve problems such as low work efficiency, high labor intensity, and occupation of work time, and achieve the effects of improving work efficiency, reducing manpower, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, and the technical solutions in the embodiments of the present invention will be clearly and completely described.

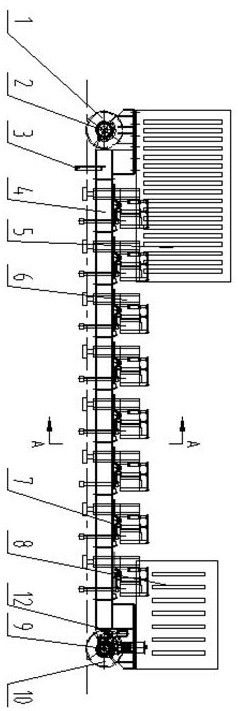

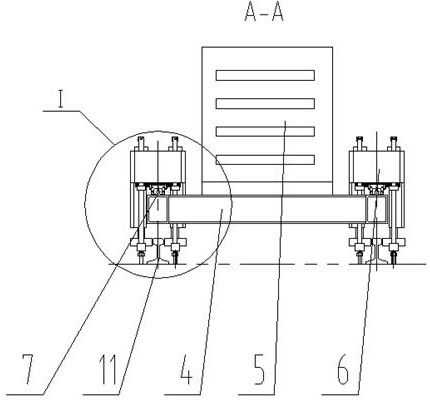

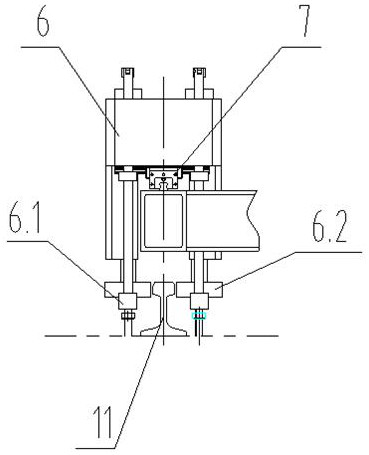

[0028] as attached figure 1 to attach Figure 6 As shown, a specific embodiment of a railway rail fastener bolt tightening device of the present invention is provided, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] as attached figure 1 As shown, a bolt tightening device for railway rail fasteners includes a base bracket 4, the base bracket 4 is connected with the driven traveling mechanism 1 and the active traveling mechanism 10; the traveling distance detection device 2 is connected with the driven traveling mechanism 1, three in one The reducer 9 is connected to the active traveling mechanism 10 through a locking disc; the bolt position detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com