Conductive rotary table

A turntable and conductive layer technology, applied in the field of additive and subtractive material manufacturing, can solve the problems of wire winding on the workbench, overall electrification of components, and high cost, and achieve the effects of avoiding wire winding problems, good insulation effect, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

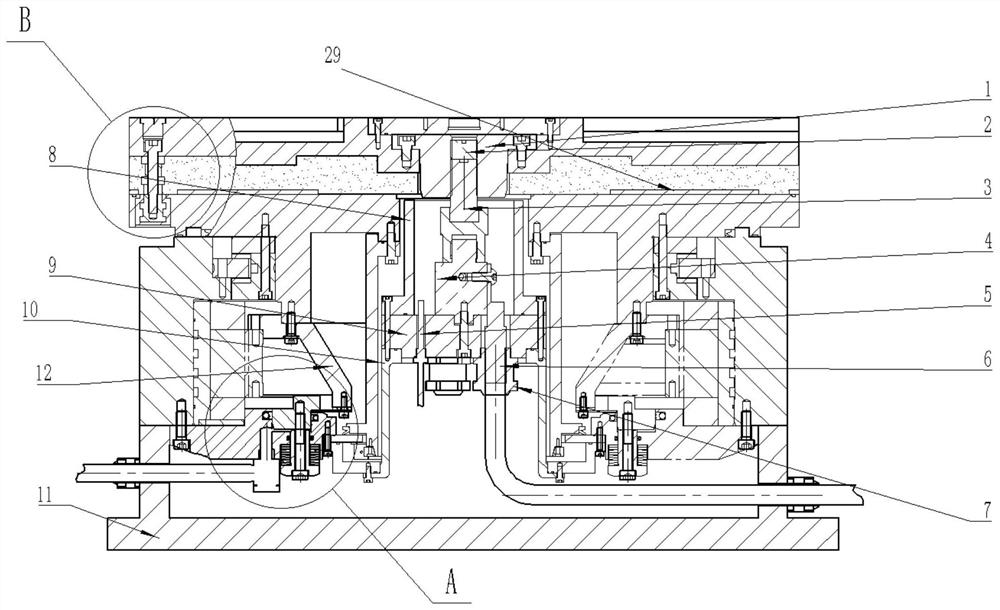

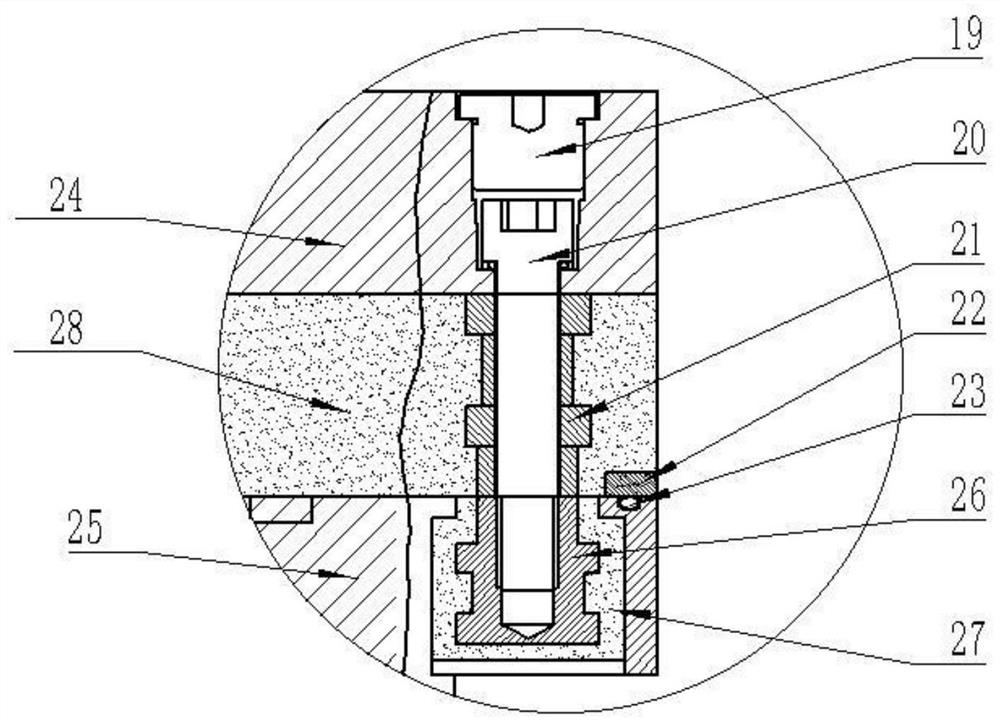

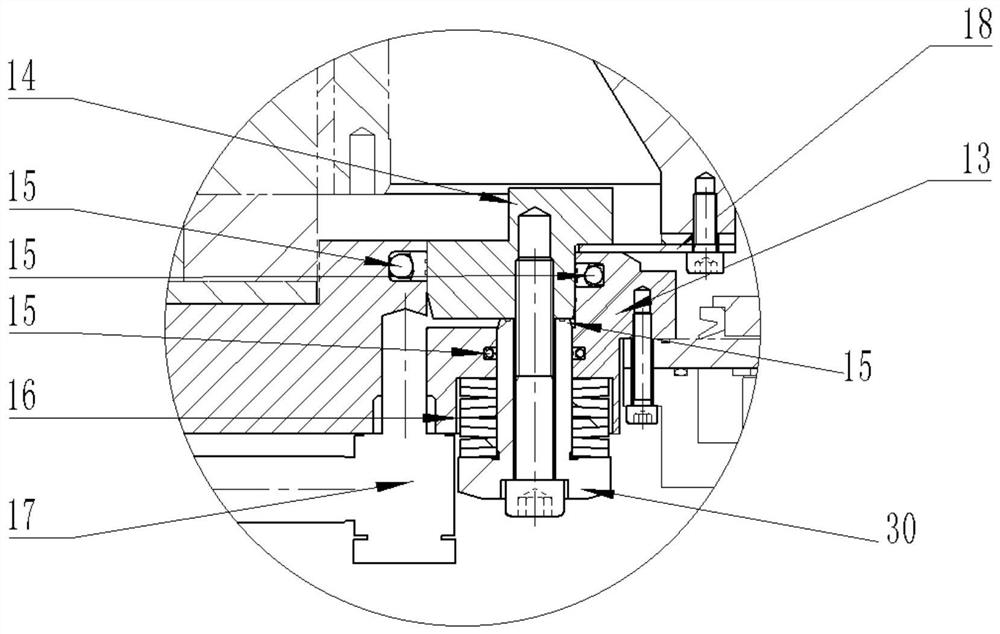

[0032] A conductive turntable, including a workbench, a mandrel 1, an electric slip ring 3, and a collector column 4; the electric slip ring 3 includes a rotating end and a fixed end, and the mandrel 1 is connected to the rotating end of the electric slip ring Connection; the fixed end of the electric slip ring 3 is connected to the collector column 4, the lower end of the collector column 4 is provided with a connecting plate 9, the lower end of the connecting plate 9 is provided with a bracket 10, and the bracket 10 is connected with the fixed plate 13 in the clamping mechanism , the connection plate 9 is provided with a temperature sensor 5 and an external cable 6; the upper plane of the connection plate 9 is provided with a protective plate 8, and the workbench includes a conductive layer 24, an insulating layer 28, and a lower workbench 25; the conductive layer 24, The insulating layer 28 and the lower workbench 25 are sequentially connected from top to bottom through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com