Automatic cleaning machine for automobile parts

A technology of auto parts and automatic cleaning machine, which is applied in the field of auto parts, can solve the problems of high cleaning labor intensity and unclean cleaning, and achieve the effect of low labor intensity, high cleaning efficiency and guaranteed cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

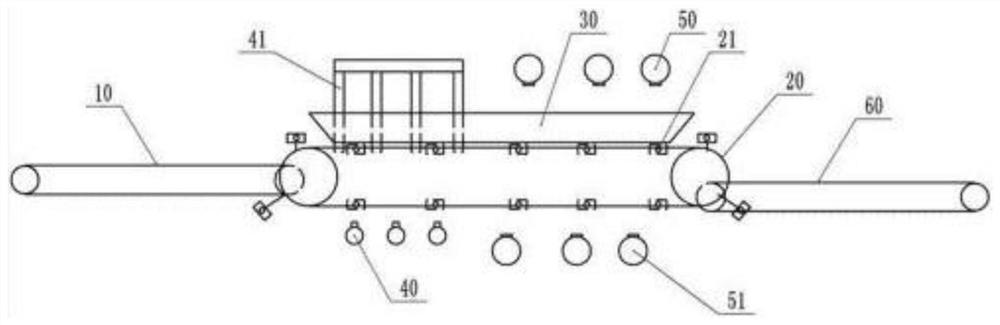

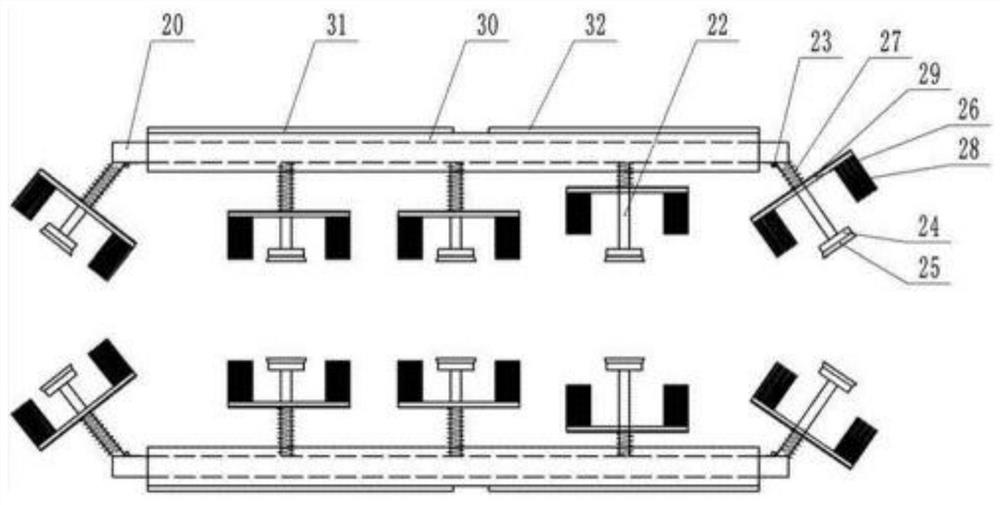

[0025] The reference signs in the accompanying drawings include: the first conveyor belt 10, the conveyor chain 20, the clamping unit 21, the clamping rod 22, the torsion spring 23, the rotary block 24, the suction cup 25, the horizontal block 26, the spring 27, the brush 28 , magnetic block 29, support plate 30, first magnetic strip 31, second magnetic strip 32, shower head 40, brush 41, upper air jet pipe 50, lower air jet pipe 51, second conveyor belt 60.

[0026] Such as figure 1 , figure 2 As shown, the auto parts automatic cleaning machine includes a first conveyor belt 10, a clamping transmission mechanism, a scrubbing mechanism, a drying mechanism and a second conveyor belt 60; the clamping transmission mechanism includes two oppositely arranged transmission chains 20, and the two transmission chains A plurality of clamping units 21 for clamping auto parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com