Three-dimensional toilet seat cushions and manufacturing method thereof

A manufacturing method and technology of a toilet seat, applied in the three-dimensional toilet seat cushion and its manufacturing field, to achieve the effect of avoiding cold touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described based on the drawings.

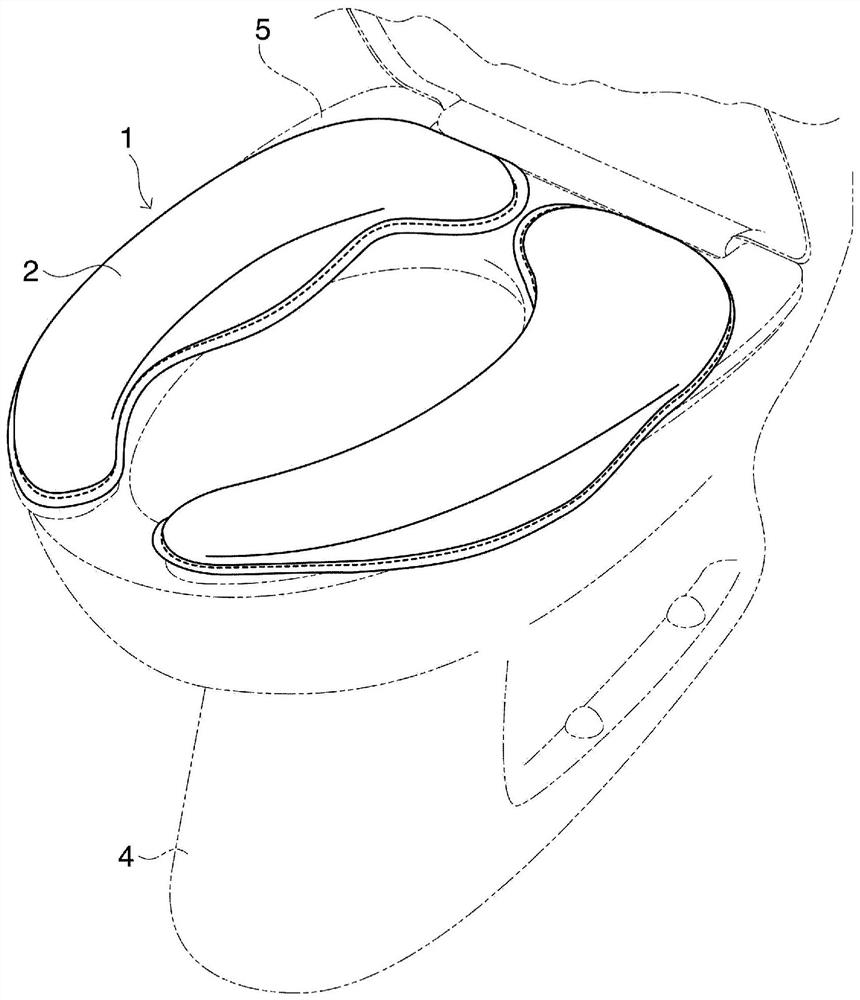

[0049] Such as figure 1 As shown, the toilet seat 1 is symmetrically formed as a pair, mounted on the toilet seat 5 at the upper end of the toilet 4 for use, and arranged so as not to interfere with the operation of the cleaning nozzle (not shown).

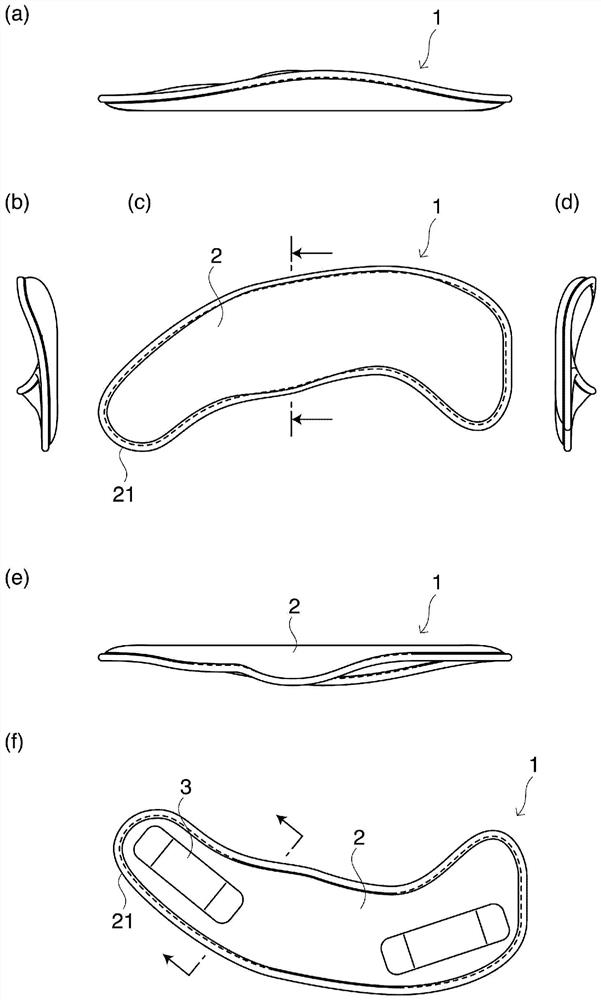

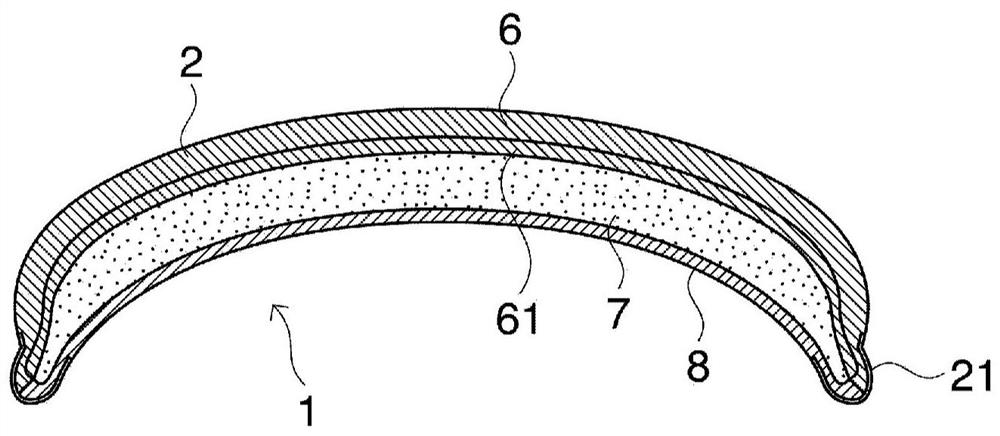

[0050] Such as Figure 2 to Figure 5 As shown, the toilet seat cushion 1 includes a deformed crescent-shaped main body 2 and a fixing part 3 for assembling on the toilet seat. as from figure 2 As clearly seen in each figure of , the toilet seat 1 is three-dimensional, and is attached to the toilet seat 5 so as to cover and follow the three-dimensional shape of the toilet seat 5 .

[0051] Regarding the size of body 2, such as Figure 6 As shown, when measured on a flat surface, H is 380 mm to 450 mm, W is 170 mm to 210 mm, W1 is 100 mm to 140 mm, W2 is 110 mm to 140 mm, and W3 is 100 mm to 130 mm. Here, H is the longitudinal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com