Double-station weighing intelligent metering special machine

A dual-station, weighing technology, applied in the direction of weighing, automatic feeding/discharging weighing equipment, measuring devices, etc., can solve the problems of single-function metering and weighing machines, low material metering efficiency, etc., and achieve lightening Work difficulty, increase feeding speed, and meet the effect of rapid production demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

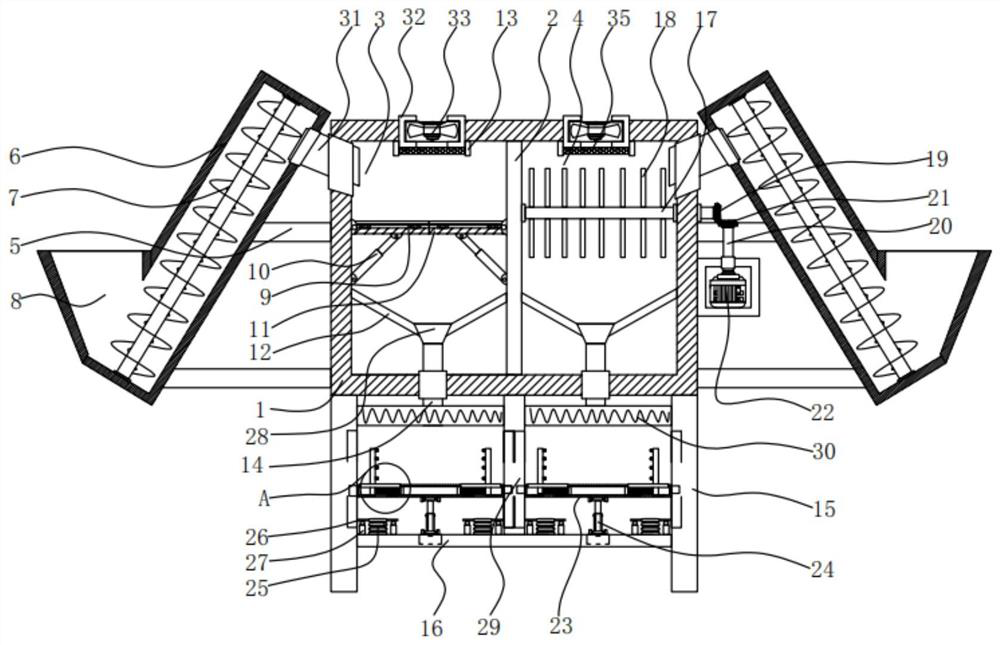

[0023] The following is attached Figure 1-3 The present invention is described in further detail.

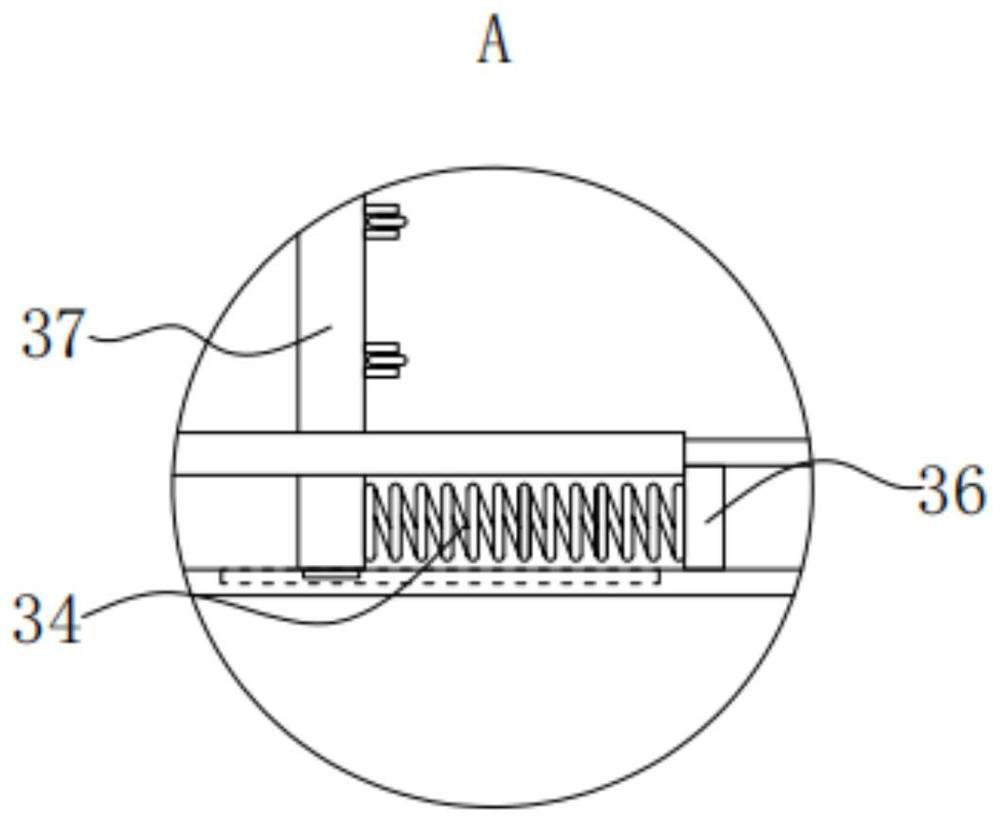

[0024] A dual-station weighing intelligent metering machine, such as Figure 1-3 As shown, including the box body 1, the middle part of the box body 1 inner cavity is vertically provided with a riser 2 that divides the box body 1 into the first cavity 3 and the second cavity 4, and the outer wall of the box body 1 is provided with a Support plate 5, the outer end of support plate 5 is all inclined to be provided with a feeding box 6, and the inner cavity of feeding box 6 is rotatably parallel to the screw shaft 7 of feeding box 6, and the top of feeding box 6 bottoms is provided with a top that is open. The top of the material storage box 8 and the feeding box 6 are all provided with a feed pipe 31 extending to the top of the first inner cavity 3 and the second inner cavity 4, and the inner side wall of the first cavity 3 can be rotatably provided with a rotating plate 11 A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com