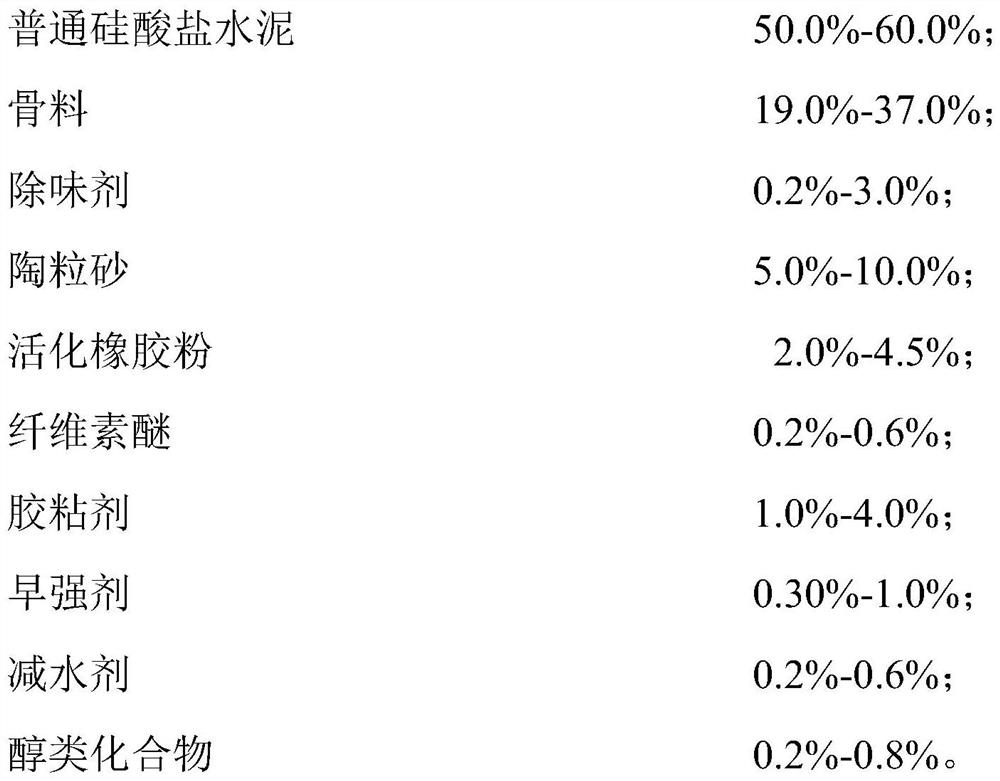

A kind of light-weight tile adhesive for realizing thick layer pasting and preparation method thereof

A tile adhesive, light-weight technology, applied in the field of chemical materials for construction, can solve the problems of high price, increased cost of tile adhesive, and direct thick layer pasting without explanation, etc., to achieve reduced elastic modulus, outstanding lateral deformation ability, and improved The effect of odor removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the present invention provides a method for preparing the light-weight tile adhesive for realizing thick layer sticking, the method comprising the following steps:

[0034] S1: stirring the activated rubber powder and the alcohol compound uniformly, then adding the deodorant, stirring uniformly to obtain component A;

[0035] S2: Stir the ordinary Portland cement, add the aggregate, adhesive, cellulose ether, water reducing agent and early strength agent to the ordinary Portland cement simultaneously, stir for 2-5 min, and then add the The ceramsite sand is stirred for 1-2 minutes, and finally the component A is added, and the mixture is stirred for 1-2 minutes to obtain the light-weight tile adhesive for thick-layer adhesion.

[0036] In the present invention, in step S2, the ordinary Portland cement is firstly added to the stirring vessel, and the aggregate, adhesive, cellulose ether, water reducing agent and early strength agent are added during the...

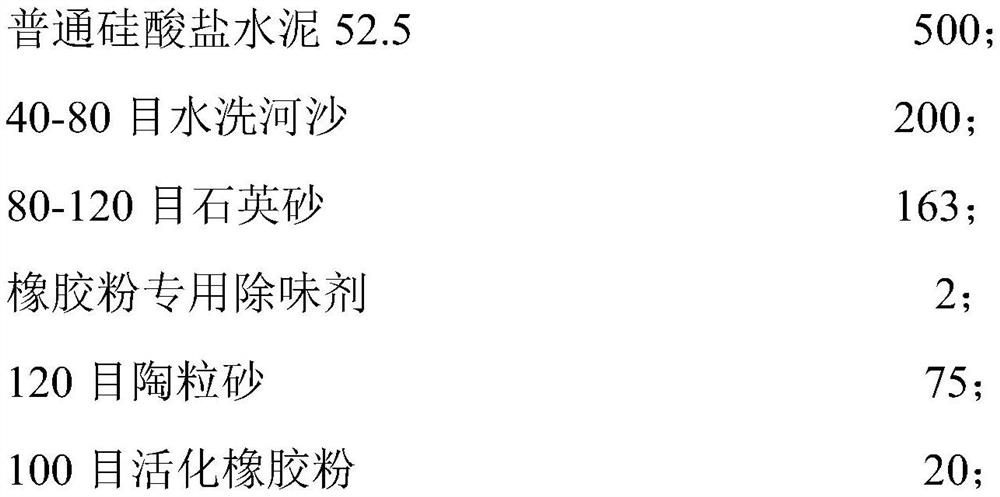

Embodiment 1

[0050] The present embodiment provides a lightweight tile adhesive that realizes thick-layer pasting, and the specific weight (KG) ratio of each component is as follows:

[0051]

[0052]

Embodiment 2

[0054] The present embodiment provides a lightweight tile adhesive that realizes thick-layer pasting, and the specific weight (KG) ratio of each component is as follows:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com