Manufacturing device for preparing construction materials from construction waste

A technology of construction waste and building materials, which is applied in the direction of manufacturing tools, metal processing, presses, etc., can solve the problems of unfavorable reuse of construction waste and construction materials that cannot be pressed into blocks, and achieve the effect of improving the quality of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

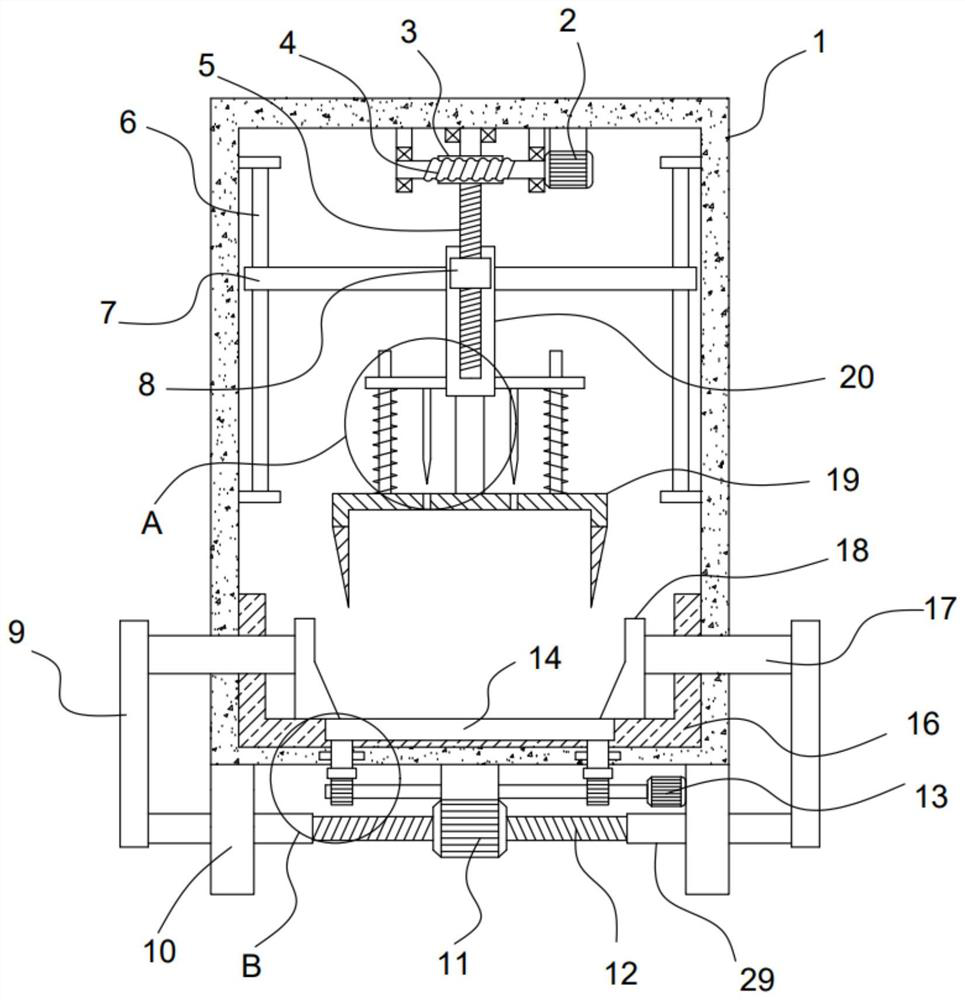

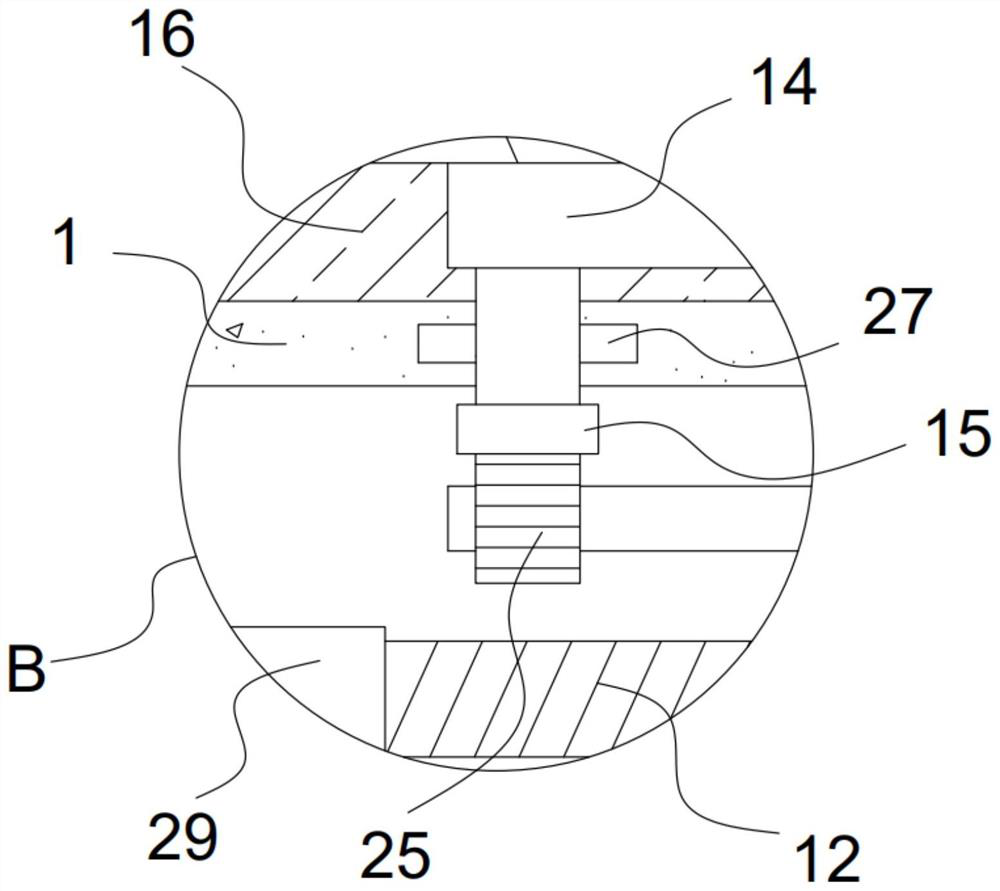

[0022] see Figure 1-4 , a production device for preparing building materials from construction waste, comprising a fixed frame 1, a support plate 10 is vertically fixed at the bottom of the fixed frame 1, a manufacturing groove 16 is fixed on the fixed frame 1, and a driving motor 2 is fixed on the top of the fixed frame 1 The driving motor 2 is driven and connected with a vertical lifting mechanism, and the vertical lifting mechanism is driven and connected with a vertically arranged sliding sleeve 20, and the sliding sleeve 20 is provided with a pressing mechanism for suppressing construction waste, The bottom of the fixed frame 1 is fixed with a biaxial motor 11, and the biaxial motor 11 is driven and connected with a pair of translation mechanisms. There is a sliding pallet 14, the sliding pallet 14 slides horizontally through the production groove 16, the upper surface of the sliding pallet 14 is flush with the inner bottom surface of the production groove 16, and the su...

Embodiment 2

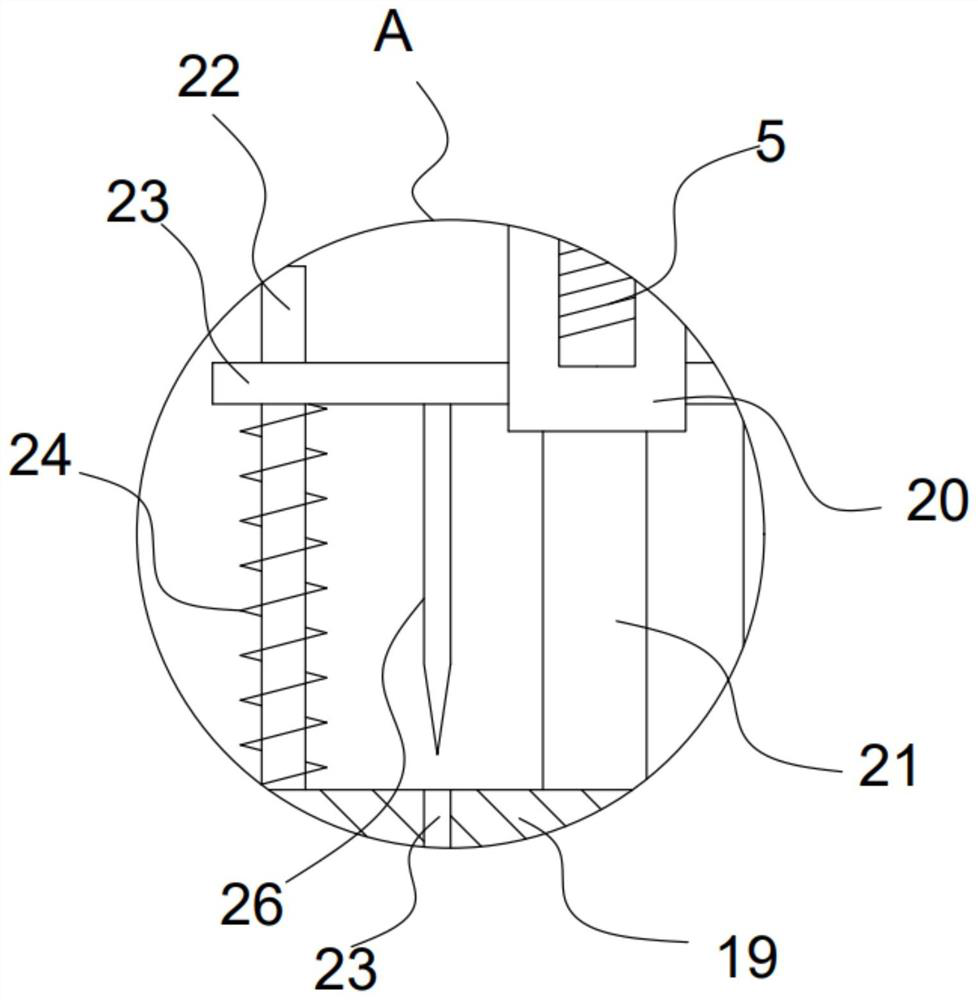

[0028] On the basis of Embodiment 1, in addition, the pressing groove plate 19 of the device is vertically penetrated with several extension holes 28 distributed at equal intervals, and each extension hole 28 is vertically corresponding to the bottom of the horizontal plate 23. The dividing blade 26.

[0029] After pressing the groove plate 19 to block the construction waste, the sliding sleeve 20 moves down under the guidance of the limit rod 22. At this time, the spring coil 24 elastically compresses, and at the same time, the partition blade 26 moves down vertically and penetrates the horizontal The plate 23 extends to the inside of the pressing groove plate 19 to realize the cutting and dividing of the pressed construction waste material into blocks to obtain several block construction materials of the same size.

[0030] Further, the translation mechanism of the device includes a sliding column 17 that slides through the fixed frame 1 and the side wall of the groove 16, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com