Hot-press forming die for panel of large cabinet air conditioner

An air-conditioning cabinet machine and thermoforming technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low product yield, unable to mass-produce, imprints that cannot be hidden, and large-scale air-conditioning panels that cannot be mass-produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

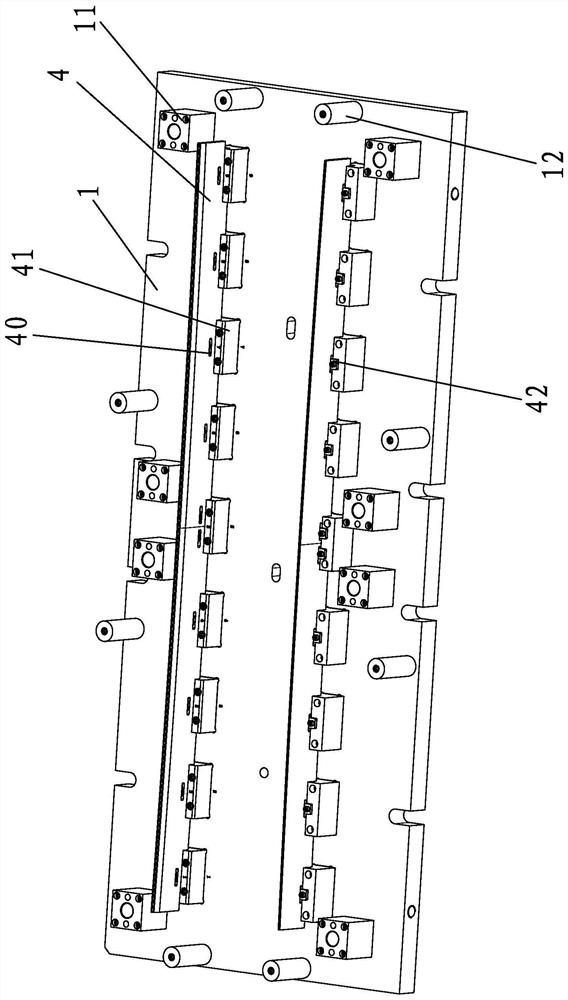

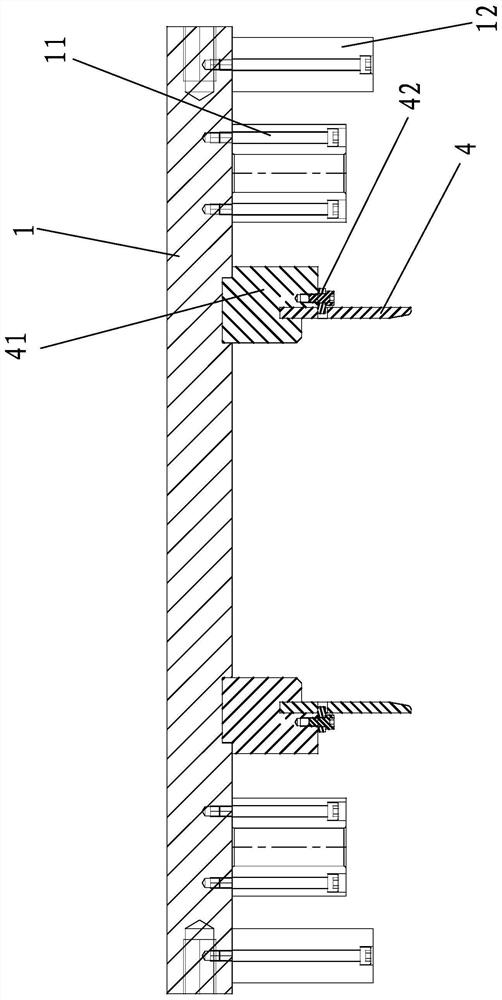

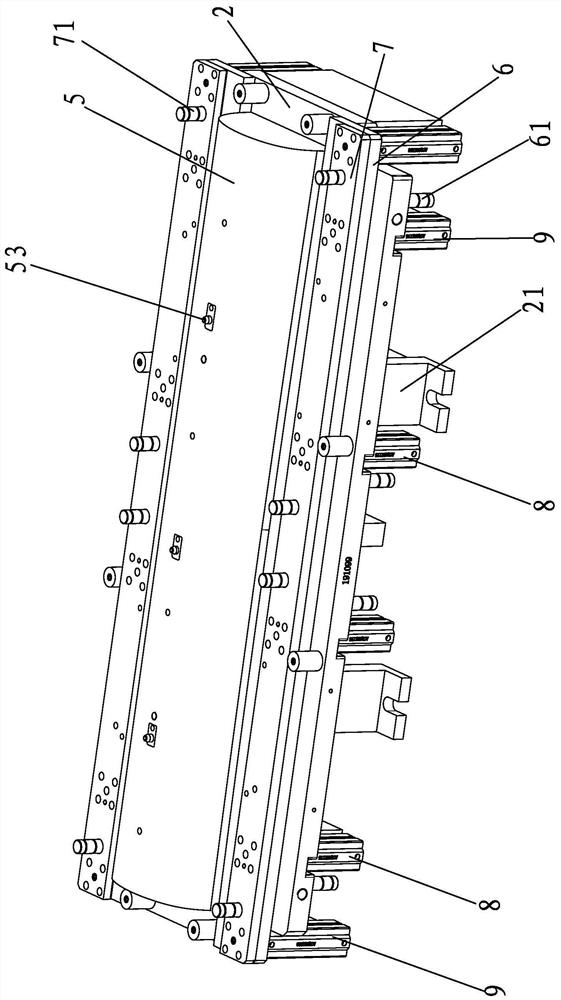

[0026] A kind of hot-press forming die of large-scale air-conditioning cabinet machine panel of the present invention, such as Figure 1-9 As shown, it includes an upper mold base 1 and a lower mold base 2. The upper mold base 1 and the lower mold base 2 are all strip structures extending along the length direction of the panel of the large air-conditioning cabinet. There is an external heating plate 3 that can move out of the space between the upper mold base and the lower mold base. This external heating plate 3 is a current product, which can adjust different heating temperatures and is set separately from the upper mold base and the lower mold base. , when in use, the manipulator is used to directly move in or out of the forming mold.

[0027] The length direction of the upper mold base 1 and the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com