Electrical comprehensive test bed for tobacco primary processing workshop

A comprehensive test bench and workshop technology, which is applied in the field of electrical comprehensive test benches in silk-making workshops, can solve the problems of cluttered front wiring, easy damage to the test bench, and low safety performance, and achieves easy operation, good reliability, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

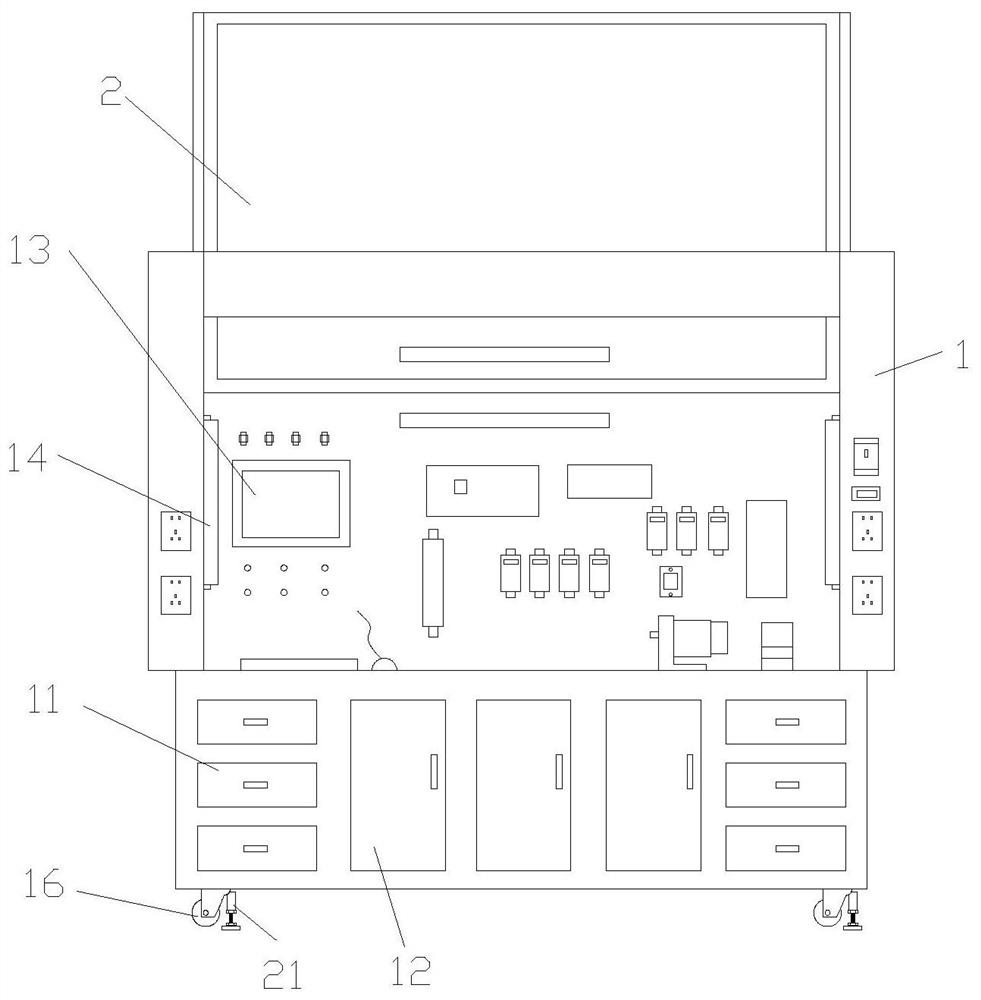

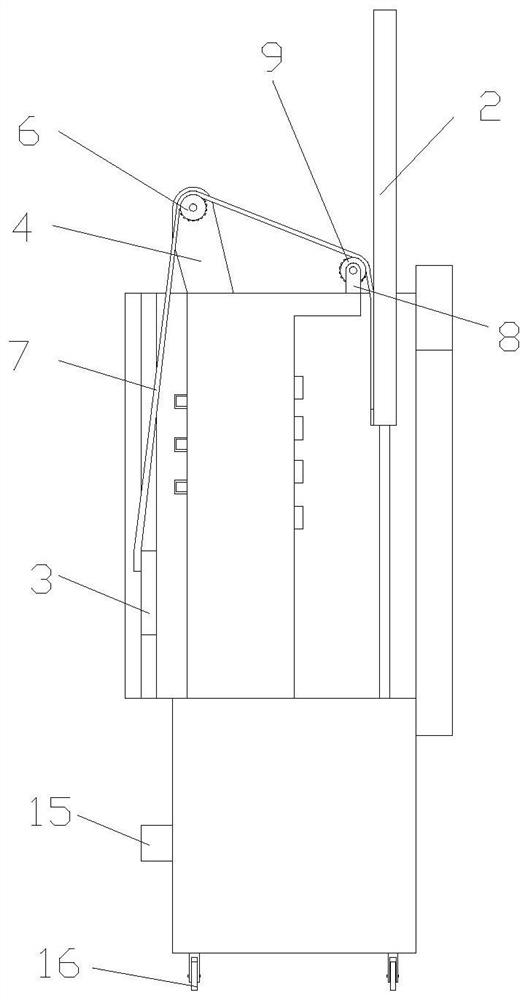

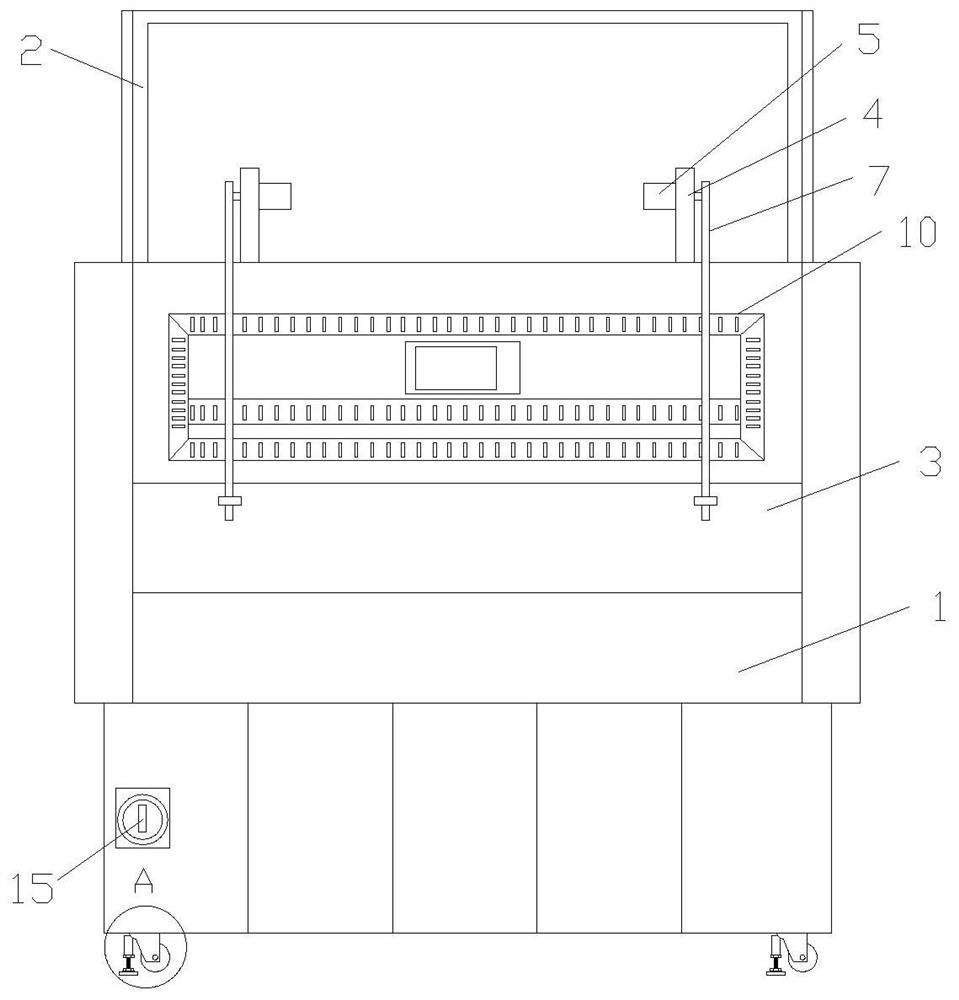

[0023] see Figure 1 to Figure 4 , this embodiment discloses a comprehensive electrical test bench for a silk workshop, comprising a bench body 1, the front side of the bench body 1 is slidably provided with a glass door 2 capable of sliding vertically, and the rear side of the table body 1 is slidably provided with a The counterweight plate 3 that slides vertically, the top of the table body 1 is provided with a first support base 4, a motor 5 is installed on the first support base 4, and a driving gear plate 6 is fixed on the output shaft of the motor 5, and the driving gear plate 6 is wound with a toothed belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com