Device for forming plastic shell of LED lamp and application method of device

A molding device and lamp plastic technology, which is applied in the field of LED lamp plastic shell molding device, can solve the problems of unfavorable use, lack of cooling mechanism, reducing the molding speed of LED lamp plastic shell, etc., and achieves improved molding processing efficiency, simple and convenient operation, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

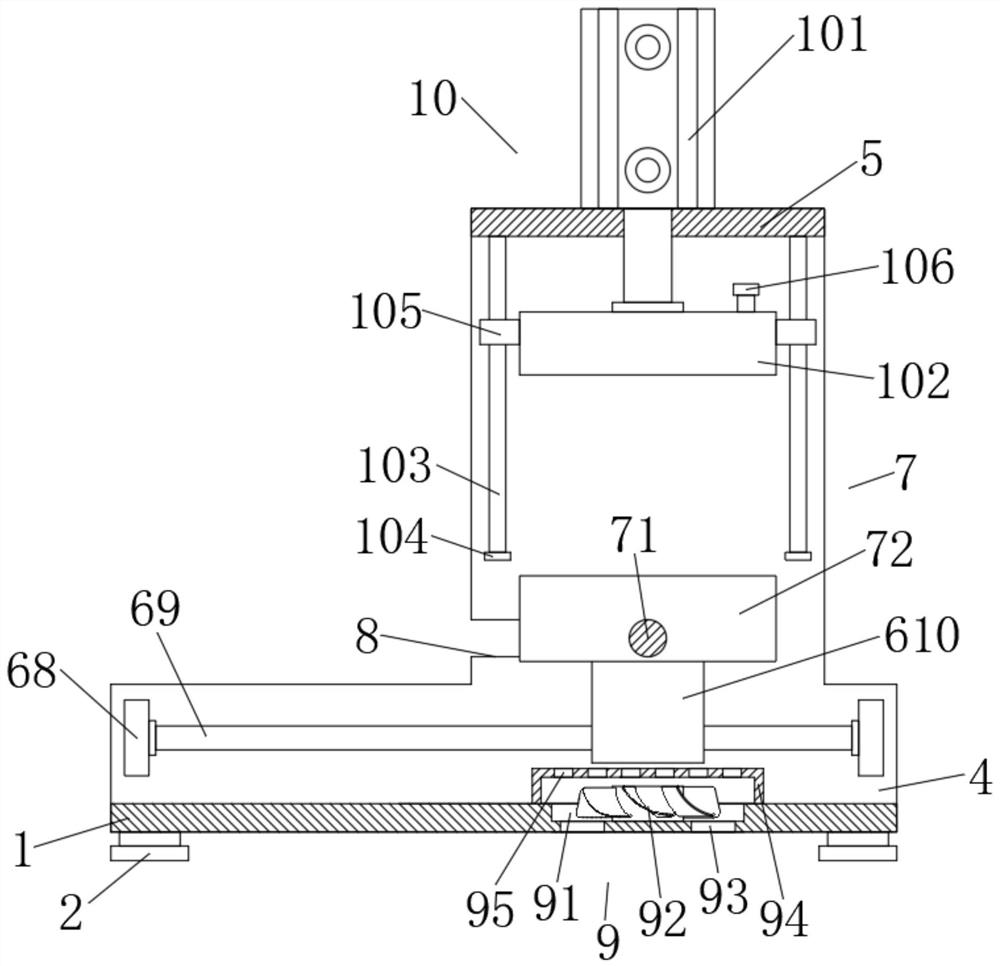

[0029] A LED lamp plastic shell molding device, comprising a bottom plate 1, the four corners of the bottom of the bottom plate 1 are fixedly connected with supporting feet 2, and the supporting feet 2 are used to facilitate the stable placement of the whole device; one end of the top of the bottom plate 1 Fixedly connected with a first fixed plate 3, the top of the bottom plate 1 away from the end of the first fixed plate 3 is fixedly connected with a second fixed plate 4, fixed between the first fixed plate 3 and the top of the second fixed plate 4 A fixed frame 5 with a U-shaped structure is connected, a moving mechanism 6 is arranged on the top of the bottom plate 1 between the first fixed plate 3 and the second fixed plate 4, and a turning mechanism 7 is arranged on the top of the moving mechanism 6, The top of the bottom plate 1 and the lower part of the moving mechanism 6 are provided with a cooling mechanism 9, and both sides of the bottom of the fixed frame 5 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com