Bread surface layer uniform material scattering device

A material spreading device and a uniform technology, which is applied in the fields of dough processing, baking, food science, etc., can solve problems such as recovery of unfixed auxiliary materials, easy falling off of slurry, and increase of surface area, so as to increase adhesion, improve production quality, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

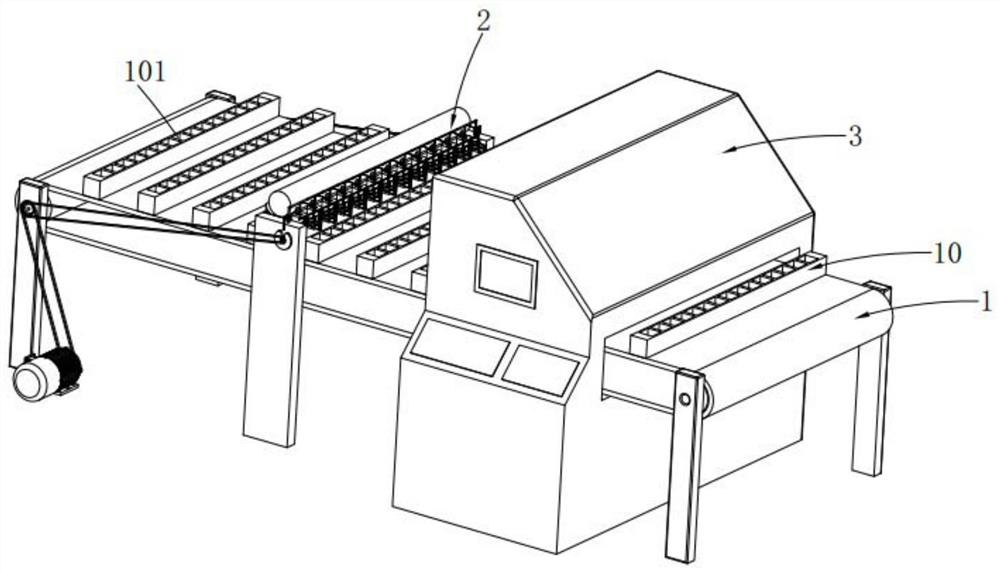

[0073] Such as figure 1 and 2 Shown, a kind of bread surface layer spreads material evenly device, it comprises:

[0074] The conveying mechanism 1, the conveying mechanism 1 uniformly conveys the carrier 10 along its conveying direction, the carrier 10 is evenly distributed along its length direction with a bearing section 101, and the bread 9 is carried in the bearing section 101;

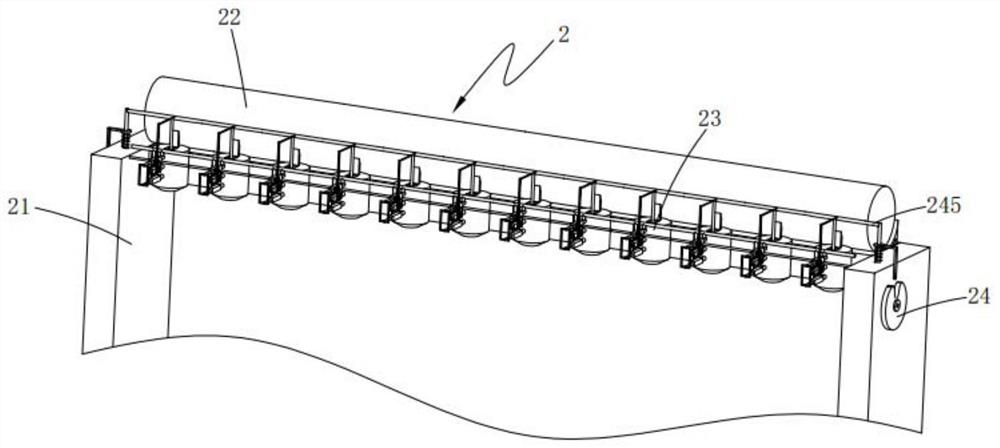

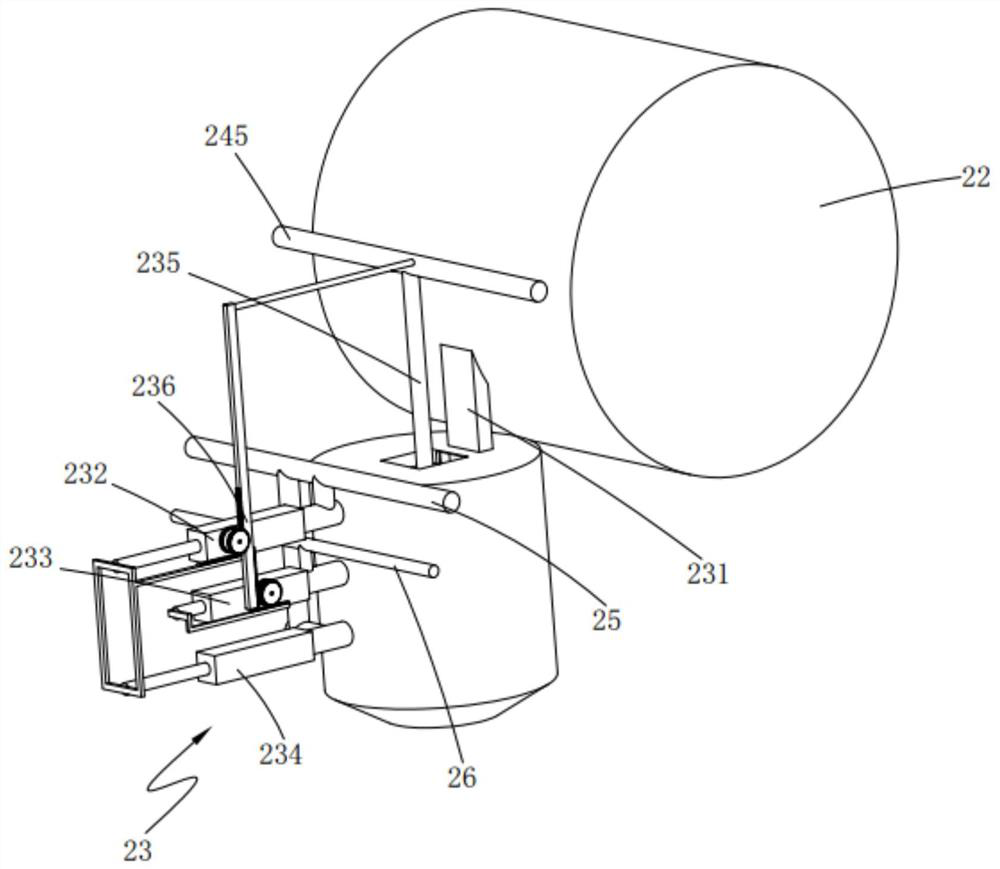

[0075] The material spreading mechanism 2, the material spreading mechanism 2 is arranged in the middle of the conveying mechanism 1, the material spreading mechanism 2 includes a base 21, a material storage cylinder 22, an oiling assembly 23 and a linkage assembly 24, the material storage cylinder 22 It is arranged on the base 21 along the width direction of the conveying mechanism 1; the oiling assembly 23 is arranged in an array along the length direction of the storage cylinder 22, and the oiling assembly 23 includes an oiling member 231, a first suction Air piece 232, powder blowing piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com