An electric power inspection robot, system and obstacle crossing method

A robot system and power inspection technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of low efficiency of obstacle surmounting, hindering the walking of inspection robots, complex obstacle surmounting structure, etc., and achieve the effect of avoiding excessive clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

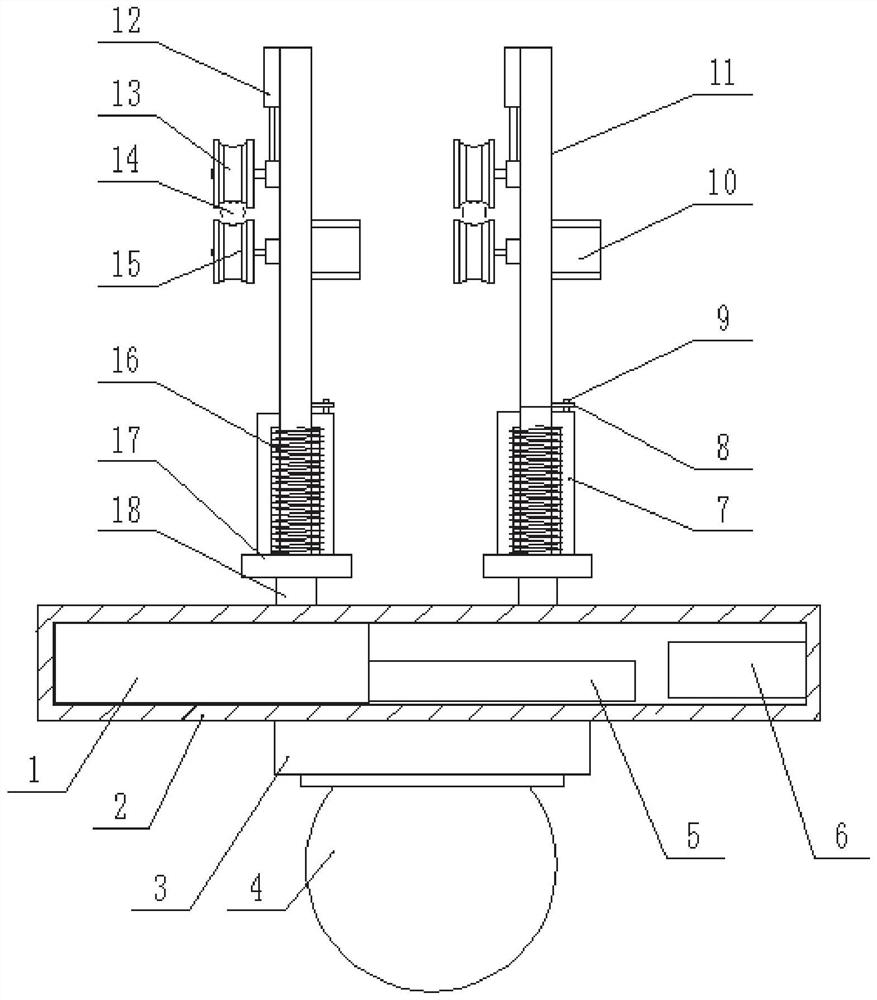

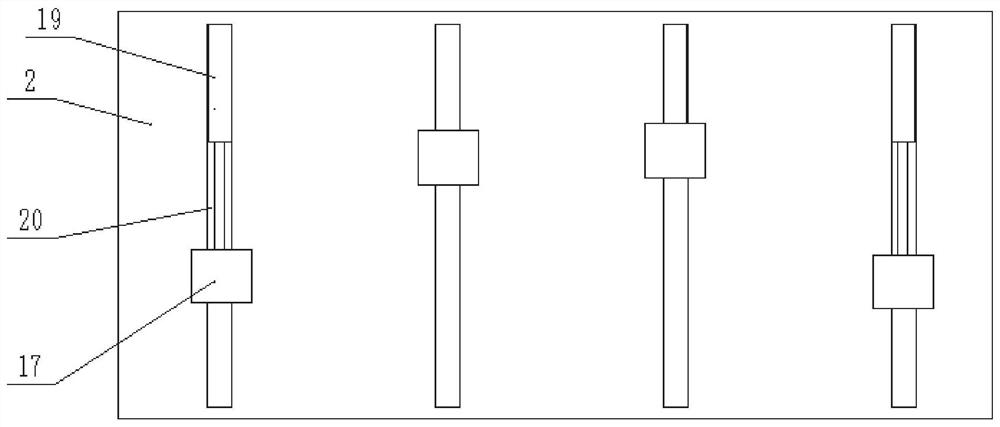

[0038] like Figure 1-2 As shown, this embodiment provides an electric power inspection robot, including a horizontally arranged base plate 2, a row of parallel chutes 20 are arranged on the upper surface of the base plate 2, and each chute 20 is provided with a slider 18, The block 18 can be slid and positioned along the chute 20 under the driving of the horizontal linear driving component. The upper part of the sliding block 18 is installed with a vertical rod 11, and the vertical rod 11 is vertically arranged with the bottom plate 2;

[0039] An upper roller 13 and a lower roller 15 are rotatably installed on the upper part of the vertical rod 11 , a ground wire space is formed between the upper roller 13 and the lower roller 15 , the ground wire space is used to pass through the ground wire 14 , and the lower roller 15 is driven by a rotating component. Driven to achieve rotation, the upper roller 13 can move vertically along the vertical rod 11 and be fixed to change the ...

Embodiment 2

[0048] This embodiment provides an electric power inspection robot system, including the above-mentioned electric power inspection robot, and also includes a host computer, the host computer can communicate with the controller 5 to receive image information captured by the power inspection robot, and remotely control The movement of the power inspection robot.

[0049] It should be pointed out that, in this embodiment, a communication assembly is provided at the inner cavity of the base plate, and the communication assembly is used to realize the communication between the controller and the upper computer.

Embodiment 3

[0051] This embodiment provides an obstacle crossing method for a power inspection robot, which includes the following steps:

[0052] When walking along the straight line segment of the ground wire 14: the multiple poles 11 of the power inspection robot are distributed on the same straight line, and the ground wire 14 is in the ground wire space between the upper roller 13 and the lower roller 15;

[0053] When the electric inspection machine encounters the obstacle formed by the vertical clamp at the tower and the anti-vibration hammer in the straight section, the robot stops moving, and then approaches between the upper roller 13 and the lower roller 15 at the front part of the pole 11 of the obstacle The distance increases, and then the pole 11 slides with the slider 18 away from the ground wire 14;

[0054] The upper roller 13 and the lower roller 15 at the latter part of the pole 11 continue to move to the obstacle position and stop;

[0055] The first part of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com