Cable stripping device

A cable and mounting ring technology, applied in the field of electric power, can solve the problems of peeling off the cable and the cable core, and the skin of the thick cable and the cable core being tightly adhered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

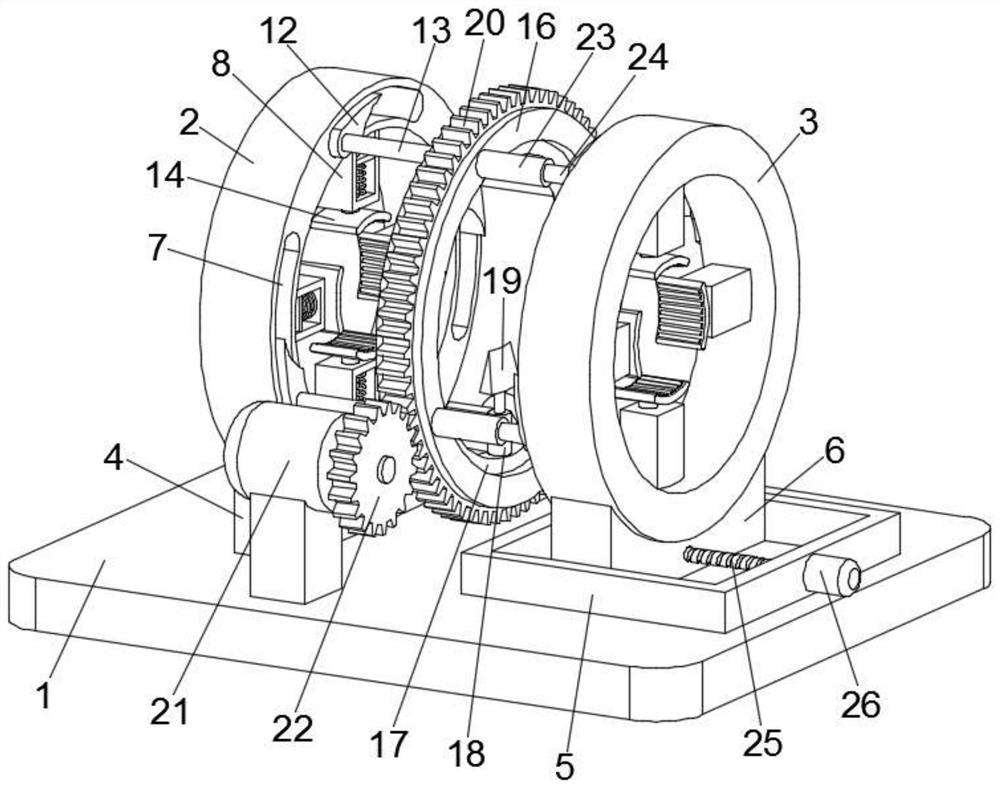

[0026]Seefigure 1 , A cable stripping device, comprising a base 1, a first support ring 2, a second support ring 3, and a mounting ring 16. The first support ring 2 is fixedly installed on the base 1 through a fixing base 4, and the base 1 is A sliding table 5 is also provided. A sliding seat 6 is fixed at the bottom of the second support ring 3. The sliding seat 6 is slidably embedded in the sliding table 5, and the mounting ring 16 is located between the first support ring 2 and the second support ring. Between ring 3;

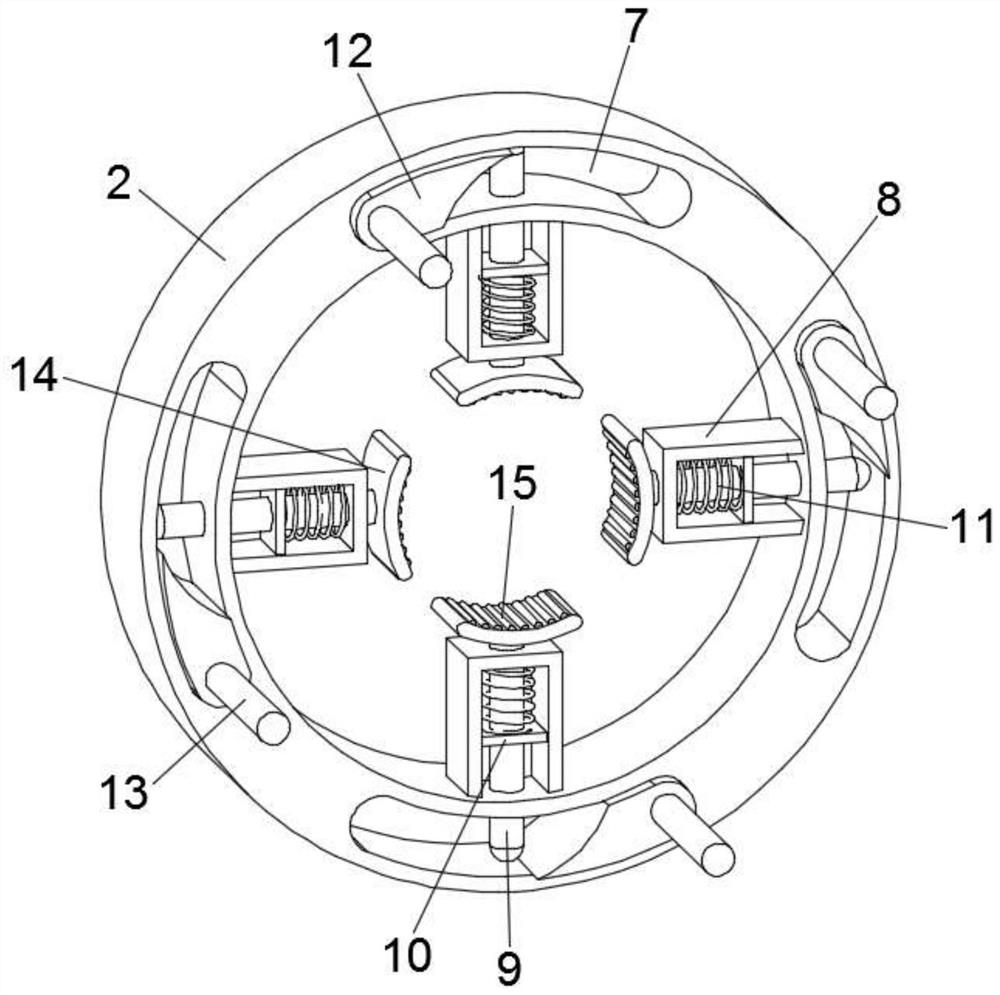

[0027]Seefigure 2 , The first support ring 2 and the second support ring 3 are evenly circumferentially distributed with several sets of clamping components, the clamping components include an arc-shaped groove 7, a fixed cylinder 8 and a pressure plate 14, the fixed cylinder 8 is provided with There is a mandrel 9 penetrating through the arc-shaped slot 7, a wedge block 12 matched with the mandrel 9 is movably clamped in the arc-shaped slot 7, and a pressure plate 1...

Embodiment 2

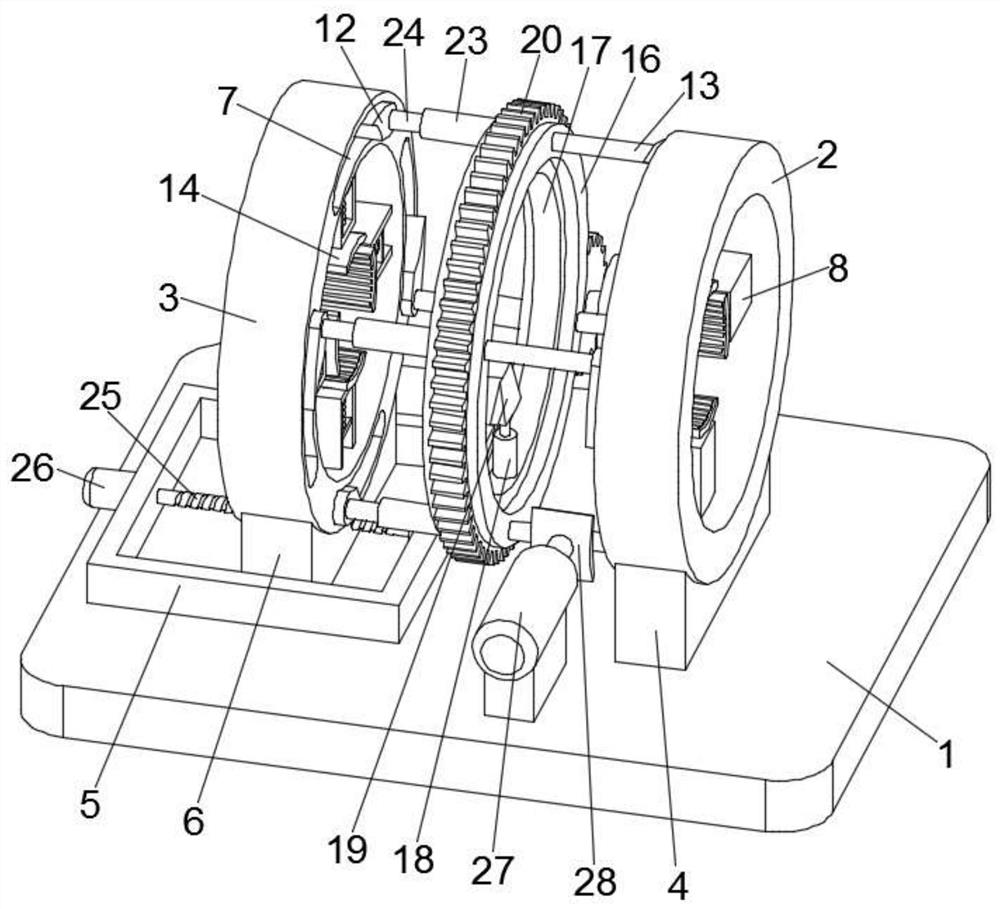

[0041]A cable stripping device includes a base 1, a first support ring 2, a second support ring 3, and a mounting ring 16. The first support ring 2 is fixedly installed on the base 1 through a fixing base 4, and the base 1 is also A sliding table 5 is provided, a sliding seat 6 is fixed at the bottom of the second support ring 3, the sliding seat 6 is slidably embedded in the sliding table 5, and the mounting ring 16 is located at the first support ring 2 and the second support ring Between 3;

[0042]The first support ring 2 and the second support ring 3 are both circumferentially evenly distributed with several groups of clamping components, the clamping components include an arc-shaped groove 7, a fixed cylinder 8 and a pressure plate 14, the fixed cylinder 8 is provided with A mandrel 9 passing through the arc-shaped slot 7, a wedge block 12 matching the mandrel 9 is movably clamped in the arc-shaped slot 7, and a pressure plate 14 is installed on the end of the mandrel 9 away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com