Textile material tensile strength detection device

A technology for tensile strength and detection devices, applied to measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problems of difficult cloth fixing and insufficient clamping, and improve the safety of detection , prevent fabric damage, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

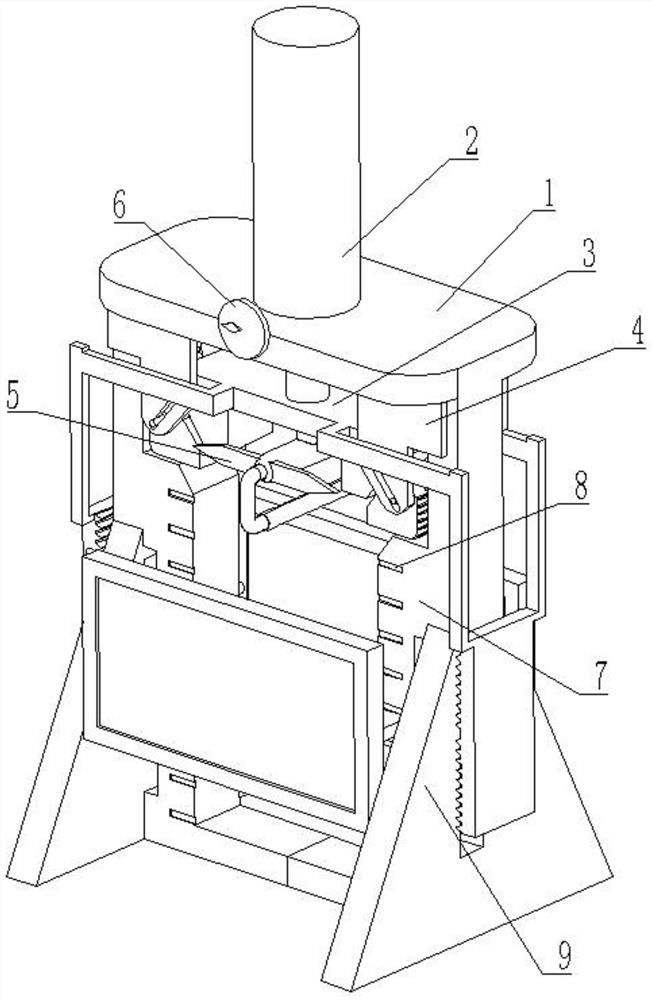

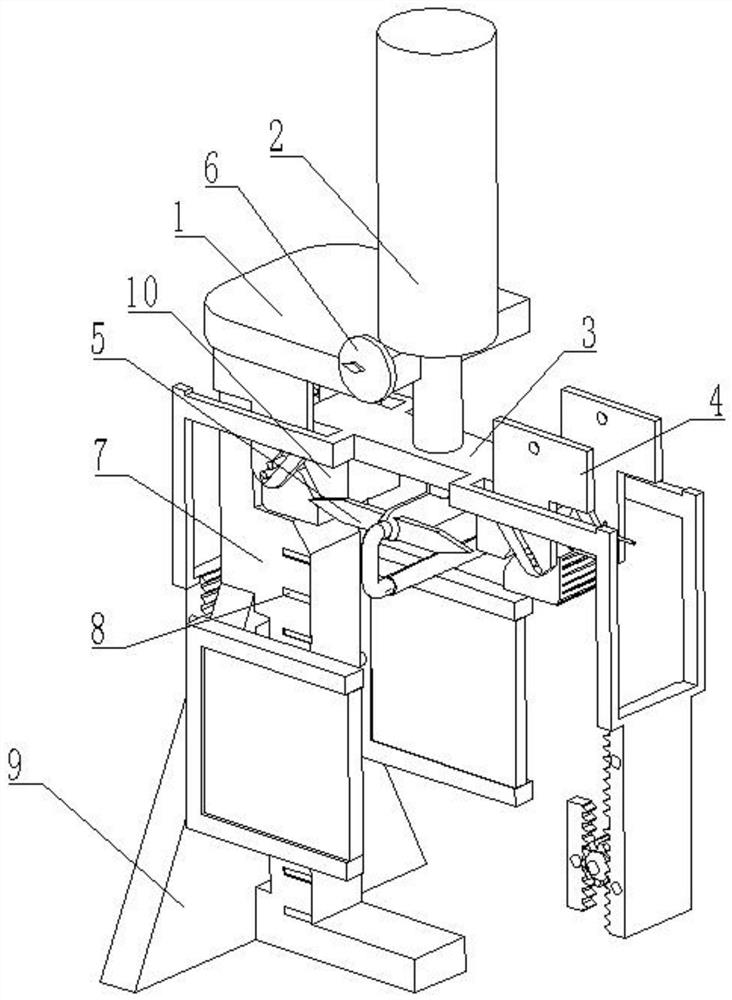

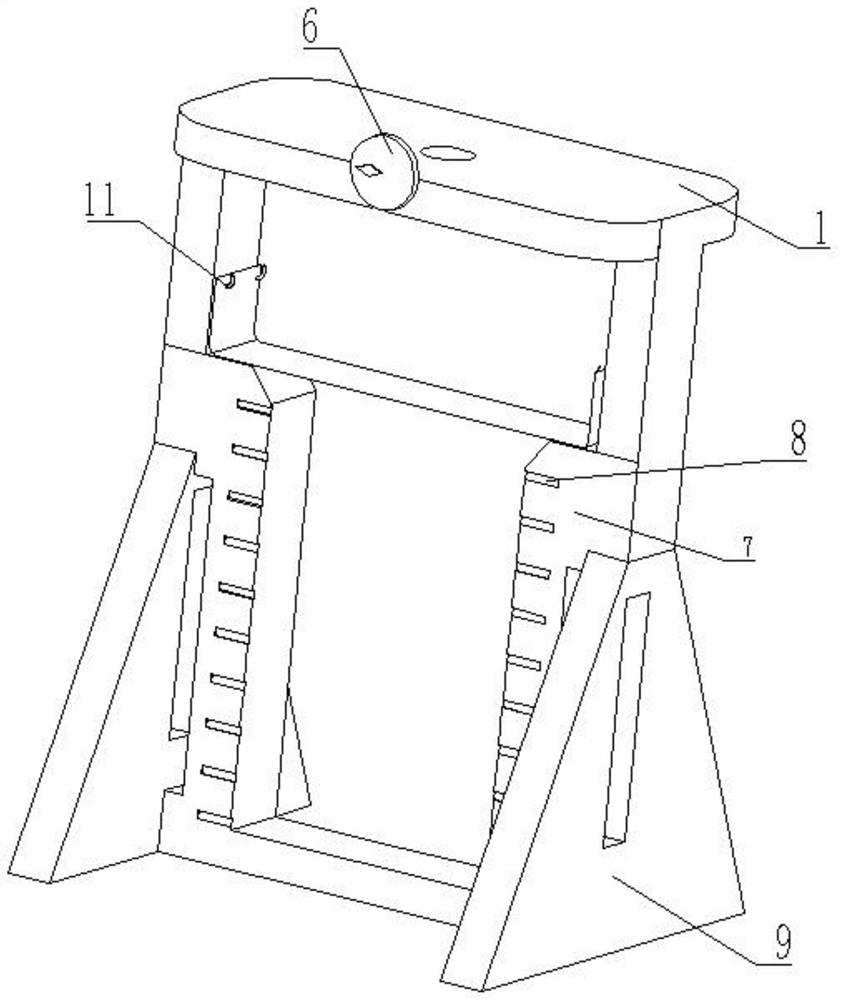

[0031] see Figure 1-7 , a textile material tensile strength detection device, comprising a frame 1, the upper surface of the frame 1 is fixedly connected with a telescopic cylinder 2, the output end of the telescopic cylinder 2 is fixedly connected with a pressing plate 3, and the surface of the pressing plate 3 is provided with a detection mechanism 5 , the surface of the frame 1 is fixedly connected with a display panel 7, the front of the display panel 7 is provided with a scale line 8, the front of the frame 1 is fixedly installed with a pressure gauge 6, and the bottom of the frame 1 is welded with a fixed plate 4, showing The surface of the plate 7 is fixedly connected with a support 9 .

[0032] The inner wall of the frame 1 is fixedly connected with pins 11, the number of pins 11 is provided in two groups, each group has two, and the two groups of pins 11 are all symmetrically distributed with the centerline of the frame 1 as the axis of symmetry; The cloth is direct...

Embodiment 2

[0039] see Figure 8 , on the basis of Embodiment 1, in this embodiment, the protection device 56 includes a rotating gear 561, the surface of the rotating gear 561 is meshed with a right tooth plate 562 and a left tooth plate 563 respectively, and the top of the right tooth plate 562 is fixedly connected to the connection The bottom of the frame 57, the top of the left tooth plate 563 is fixedly connected with a connecting slide bar 564, and the two ends of the connecting slide bar 564 are fixedly connected with a protective frame 565, and the rotating gear 561 meshed with it is driven by the right tooth plate 562 to rotate. The rotation of the rotating gear 561 will drive the movement of the connecting slide bar 564, thereby causing the protective frame 565 to rise from the bottom to improve the overall safety of the entire device.

[0040] The inside of the protective frame 565 is clamped with tempered glass 566, the axis of the rotating gear 561 is rotatably connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com