Porous biomass gas low-nitrogen combustor

A biomass gas and low-nitrogen burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient combustion of gas, large safety hazards, and insufficient mixing, so as to improve the utilization rate, Emission reduction and sufficient pre-mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

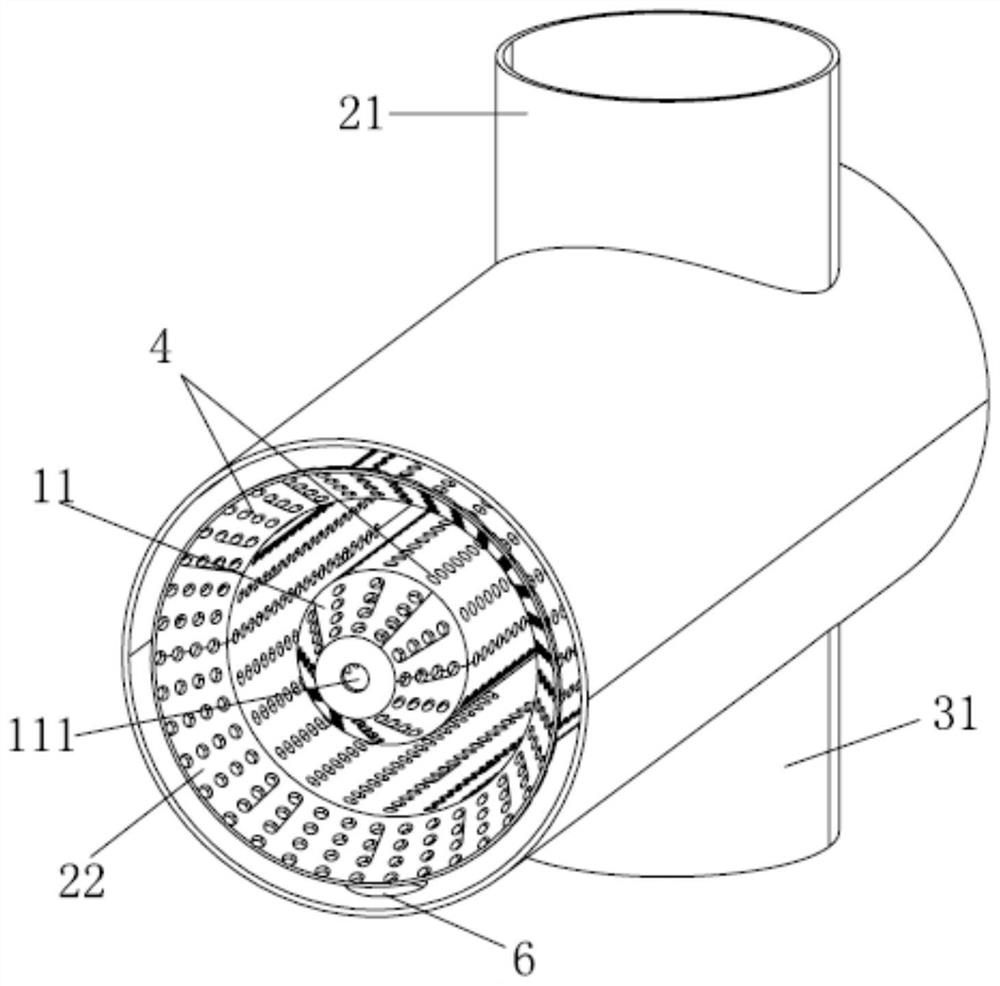

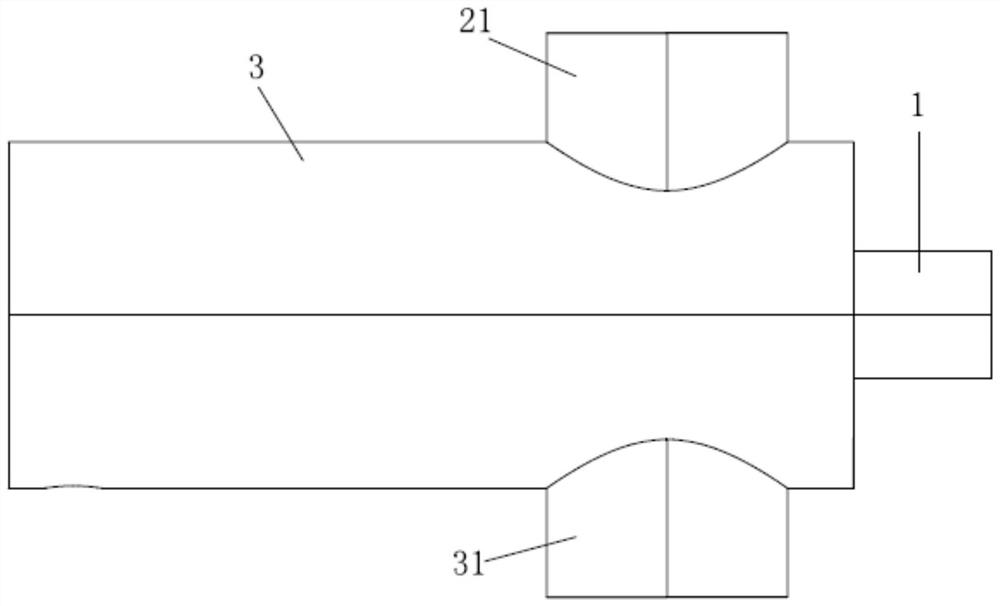

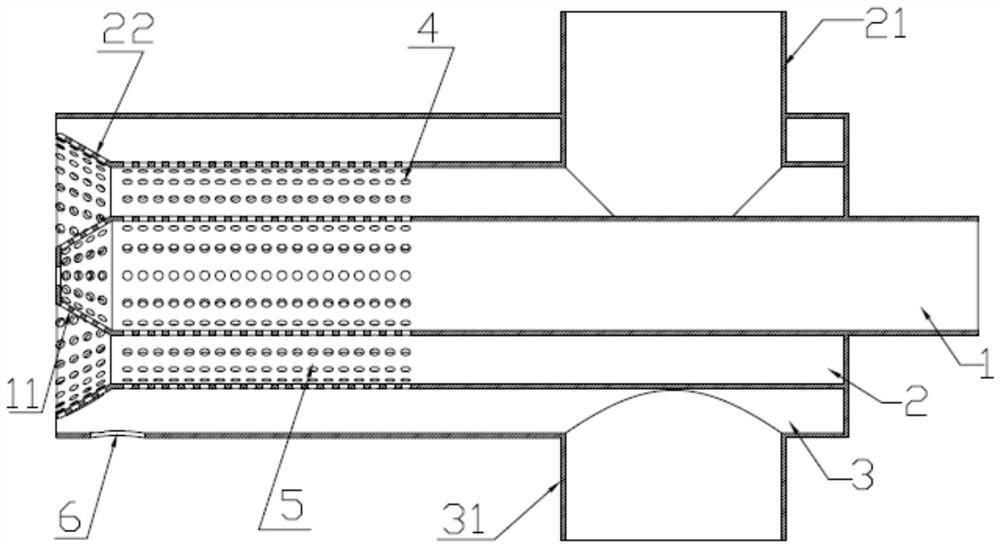

[0025] like Figure 1 to Figure 3 As shown, the porous biomass gas low-nitrogen burner shown in this embodiment includes a central air duct 1 and two gas channels 2 and auxiliary air ducts 3 arranged around the central air duct 1 from the inside to the outside. The central air duct 1 , the gas channel 2 and the auxiliary air channel 3, the outlets at the front ends of the three are flush, and the central air channel and the front part of the gas channel are provided with several air holes 4 that are evenly distributed and run through themselves, so that the central air channel, the gas channel It communicates with the front section of the auxiliary channel through air holes for the circulation of gas, thereby forming a premixing zone 5 at the front end of the gas channel, and setting the same axial length of the air holes in the central air channel and the gas channel, so that the air inside and outside Enter the gas channel for pre-mixing; the rear ends of the central air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com