Anti-abrasion uniform coal feeding device for circulating fluidized bed

A circulating fluidized bed and coal feeding device technology, which is applied in the field of boiler coal feeding devices, can solve the problems of coal pipe blockage and tempering with high concentration, reduce the potential energy of coal particles, achieve sufficient fluidization, and solve the problem of tempering and The effect of smoke recirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

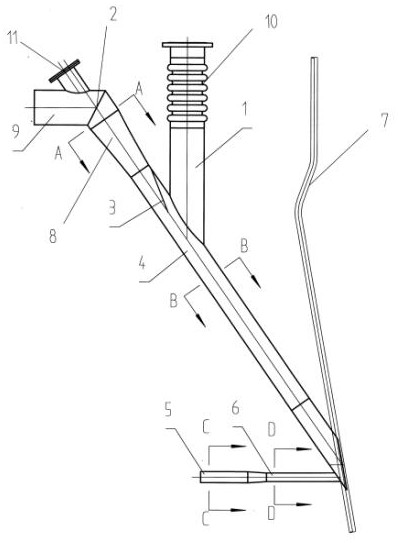

[0015] An anti-wear uniform coal feeding device for a circulating fluidized bed boiler, comprising a coal bunker, a vertical coal drop pipe 1, a coal conveying air pipe 2, a uniform coal feeding pipe 4, a uniform coal spreading air pipe 6 and a furnace The water-cooled membrane wall 7, the lower end of the vertical coal drop pipe 1 communicates with the upper part of the inclined uniform coal feeding pipe 4, and the lower end of the uniform coal feeding pipe 4 communicates with the water-cooled membrane wall 7 in the furnace. On the upper port of the uniform feed coal pipe 4, there is a coal conveying air pipe 2, which is V-shaped. The cross section of the lower pipe section 8 gradually changes from a circle to an ellipse along the inclined downward direction, the cross section of the horizontal pipe section 9 is circular, and the cross section of the uniform feed coal pipe 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com