Refractory material constructor lifting platform

A technology for construction personnel and lifting platforms, which is applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of complicated and error-prone communication and reduced construction efficiency, and achieve simple and easy manpower consumption and less manpower consumption , the effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

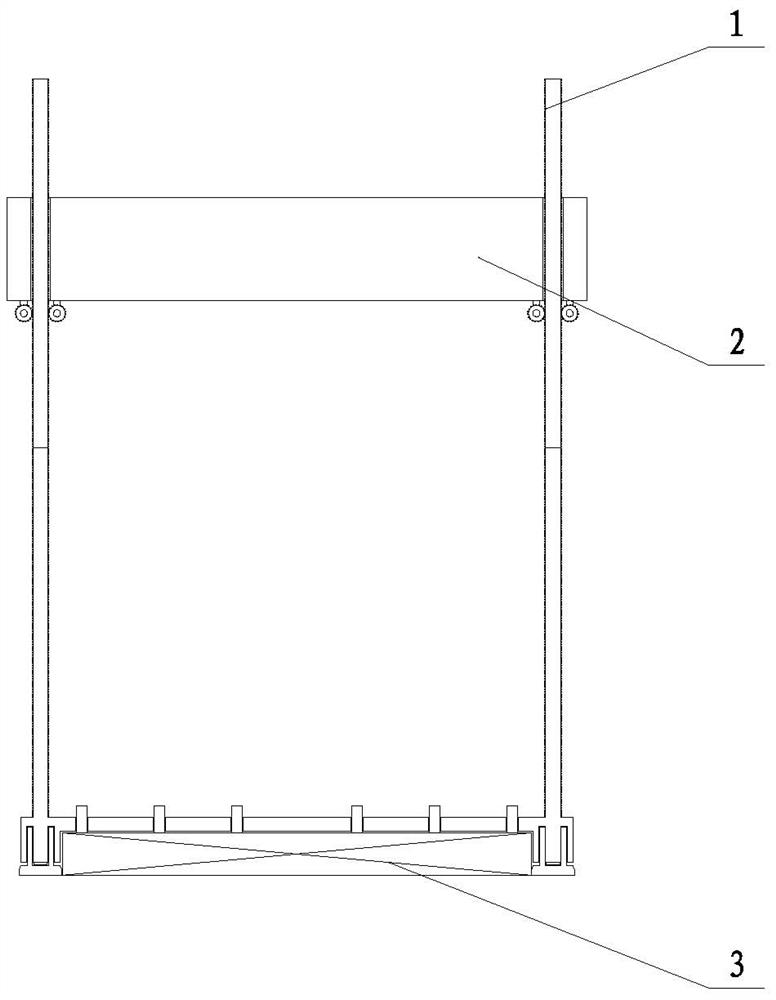

[0047] Such as figure 1 As shown, a refractory material construction personnel lifting platform includes a fixed base, a lifting platform and a plug-in guide rail bar. A counterweight is arranged in the fixed base, and at least four plug-in guide rails are arranged in a circular array on the fixed base. rod, and the lifting drive device is arranged on the lifting platform, and the lifting driving device can drive the lifting platform to move up and down along each plug-in guide rail rod.

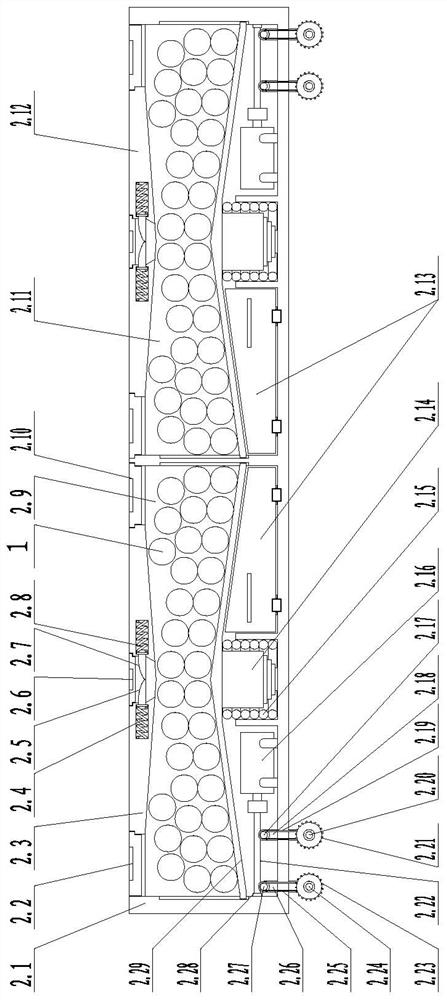

[0048] Such as figure 2 and 4 As shown, the lifting platform includes an outer shell, and a left storage rod warehouse and a right rod storage warehouse are respectively arranged on the upper left and upper right inside the outer housing, and a left warehouse body is respectively arranged on the upper part of the left storage rod warehouse and the right rod storage warehouse. Cover plate and right bin body cover plate; the left bin body cover plate and the right bin body cover plate inclu...

Embodiment 2

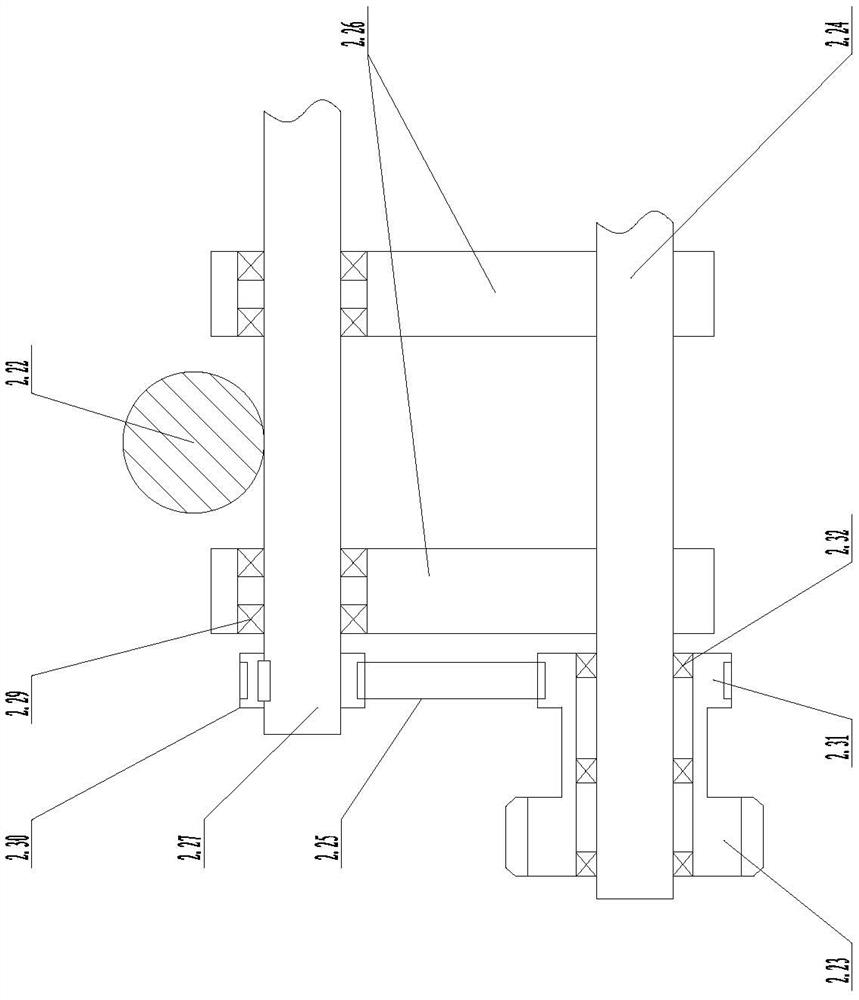

[0065] Such as Figure 11 and 12 As shown, in this embodiment, a stable support device is also included, the stable support device includes an outer support telescopic rod and an inner support telescopic rod, the extended end of the outer support telescopic rod is a fixed end and the outside of the fixed end is set The rubber support seat, the inner end of the outer support telescopic rod is a telescopic end and the telescopic end is connected to the telescopic end of the inner support telescopic rod through a telescopic controller, and the fixed end of the inner support telescopic rod is provided with an upper support insertion rod and a lower support insertion rod; An upper support socket and a lower support socket are arranged on the outer side wall of the outer shell, and the upper support insertion rod and the lower support insertion rod are respectively inserted into the upper support insertion hole and the lower support insertion hole; A corresponding pin lock hole is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com