Production method of broomcorn millet yellow wine

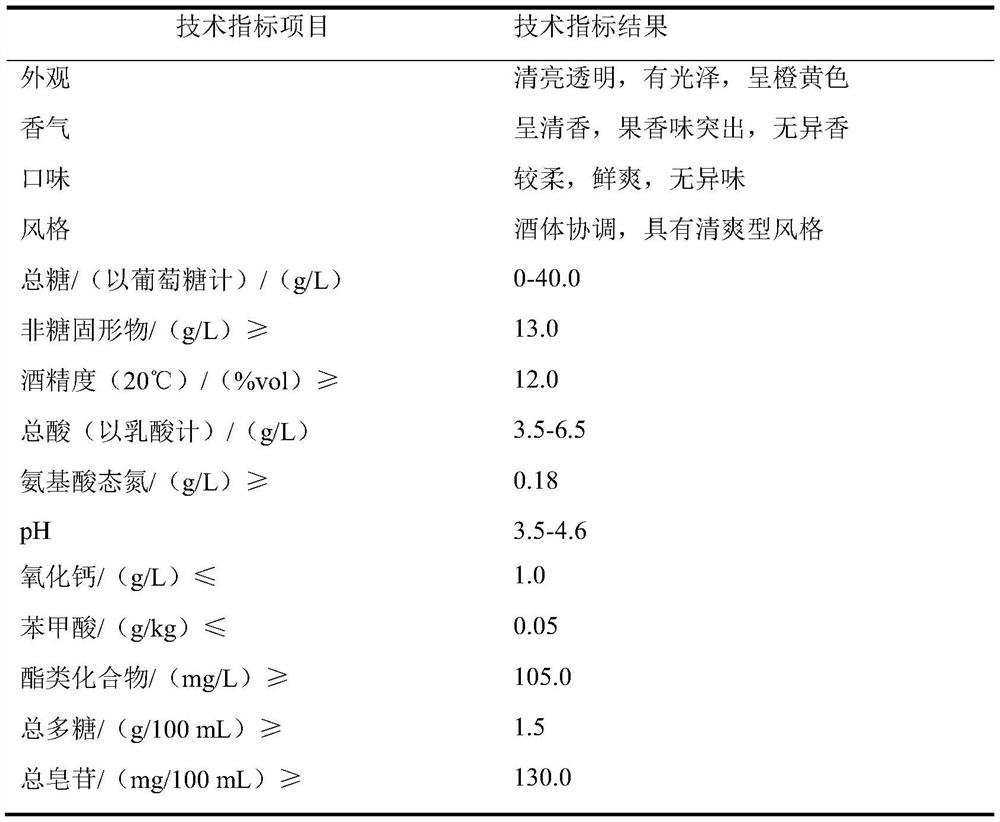

A production method and technology for rice wine, applied in the field of food manufacturing, can solve the problems of inhibiting the growth and reproduction of brewing microorganisms, affecting the flavor quality of products, unpleasant beany smell, etc., and achieving harmonious and stable flavor, pure wine body aroma, and prominent fruit flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

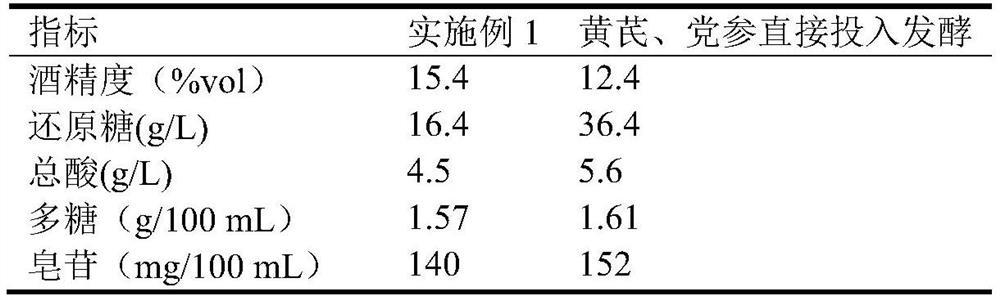

Embodiment 1

[0027] A kind of production method with millet rice wine comprises the following steps:

[0028] (1) Crushing of medicinal materials: 2 parts of Astragalus membranaceus and 4 parts of Codonopsis pilosula were dried and crushed to 40 mesh. Mix with water at a ratio of 1:20, leaching with ultrasonic (300w) assistance at 40°C for 50 minutes, filter and take the supernatant, concentrate in vacuum to 0.2 times the original volume, and set aside.

[0029] (2) Rice soaking: Weigh 100 parts of millet and soak in water at 55°C for 30 minutes, then drain the water with gauze.

[0030] (3) Cooling of steamed rice: Put the drained millet in a rice steamer and steam it until there is no white heart inside, it is cooked but not mushy, even and consistent, take it out and let it cool naturally.

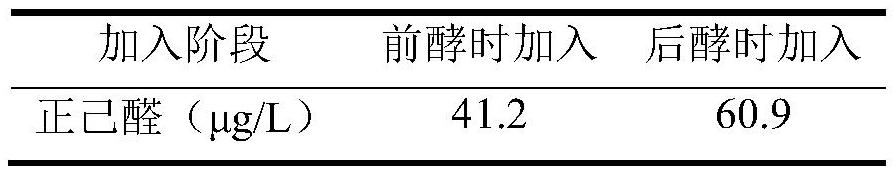

[0031] (4) Blanking: add 90 parts of water (according to the ratio of material to water 1:0.9, the proportion of auxiliary materials is based on dry rice) and mix well, and add 5 parts of crushed Q...

Embodiment 2

[0039] A kind of production method with millet rice wine comprises the following steps:

[0040] (1) Crushing of medicinal materials: 1 part of Astragalus membranaceus and 2 parts of Codonopsis pilosula were dried and crushed to 40 mesh. Mix it with water at a ratio of 1:25, leaching with ultrasonic (400w) at 50°C for 30 minutes, filter and take the supernatant, concentrate in vacuum to 0.1 times the original volume, and set aside.

[0041] (2) Rice soaking: Weigh 100 parts of millet and soak in water at 55°C for 30 minutes, then drain the water with gauze.

[0042] (3) Cooling of steamed rice: Put the drained millet in a rice steamer and steam it until there is no white heart inside, it is cooked but not mushy, even and consistent, take it out and let it cool naturally.

[0043] (4) Blanking: add 100 parts of water (according to the ratio of material to water 1:1) and mix well, and add 10 parts of crushed Qingxiang Daqu and 0.2 parts of rice wine active dry yeast activated w...

Embodiment 3

[0051] A kind of production method with millet rice wine comprises the following steps:

[0052](1) Crushing of medicinal materials: 2 parts of Astragalus membranaceus and 4 parts of Codonopsis pilosula were dried and crushed to 40 mesh. Mix with water at a ratio of 1:30, leaching with ultrasonic (300w) at 50°C for 40 minutes, filter and take the supernatant, concentrate in vacuum to 0.1 times the original volume, and set aside.

[0053] (2) Rice soaking: Weigh 100 parts of millet and soak in water at 55°C for 30 minutes, then drain the water with gauze.

[0054] (3) Cooling of steamed rice: Put the drained millet in a rice steamer and steam it until there is no white heart inside, it is cooked but not mushy, even and consistent, take it out and let it cool naturally.

[0055] (4) Blanking: Add 120 parts of water (according to the ratio of material to water 1:1.2) and mix well, and add 15 parts of crushed Qingxiang Daqu and 0.3 parts of rice wine active dry yeast activated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com