Quartz tube expanding device

A quartz tube and mounting plate technology, used in glass re-molding, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of low height adjustment accuracy, poor pipe expansion effect, height adjustment mechanism easily affected by high temperature, etc. High, easy to adjust, good pipe expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

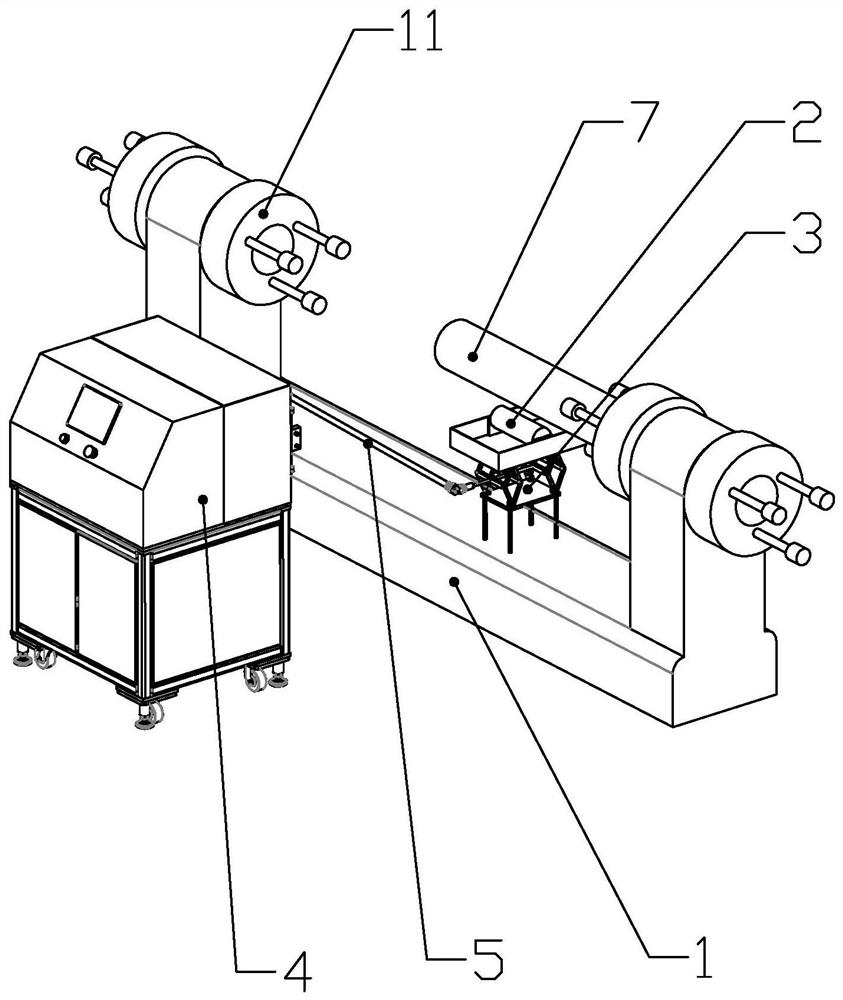

[0032]Such asfigure 1 ,figure 2 In the illustrated embodiment 1, a quartz tube expanding device includes a bed 1, a chuck 11 arranged on the bed 1 for clamping both ends of the quartz tube, and a pipe expanding mechanism, the chuck 11 is a three-jaw card The tube expansion mechanism includes a supporting roller 2, a cooling water tank 6, a lifting mechanism 3, and a welding gun (not shown in the figure) for supporting the quartz tube 7. The supporting roller 2 is made of graphite, and the supporting roller 2 is rotated and arranged in the cooling In the water tank 6, the axis of the supporting roller 2 is parallel to the axis of the quartz tube 7 and is set directly below the quartz tube 7. The bottom of the cooling water tank 6 is provided with a lifting mechanism 3, and the bottom of the lifting mechanism 3 is slidably connected to the bed 1, and the lifting mechanism 3 can Move along the length of the quartz tube 7.

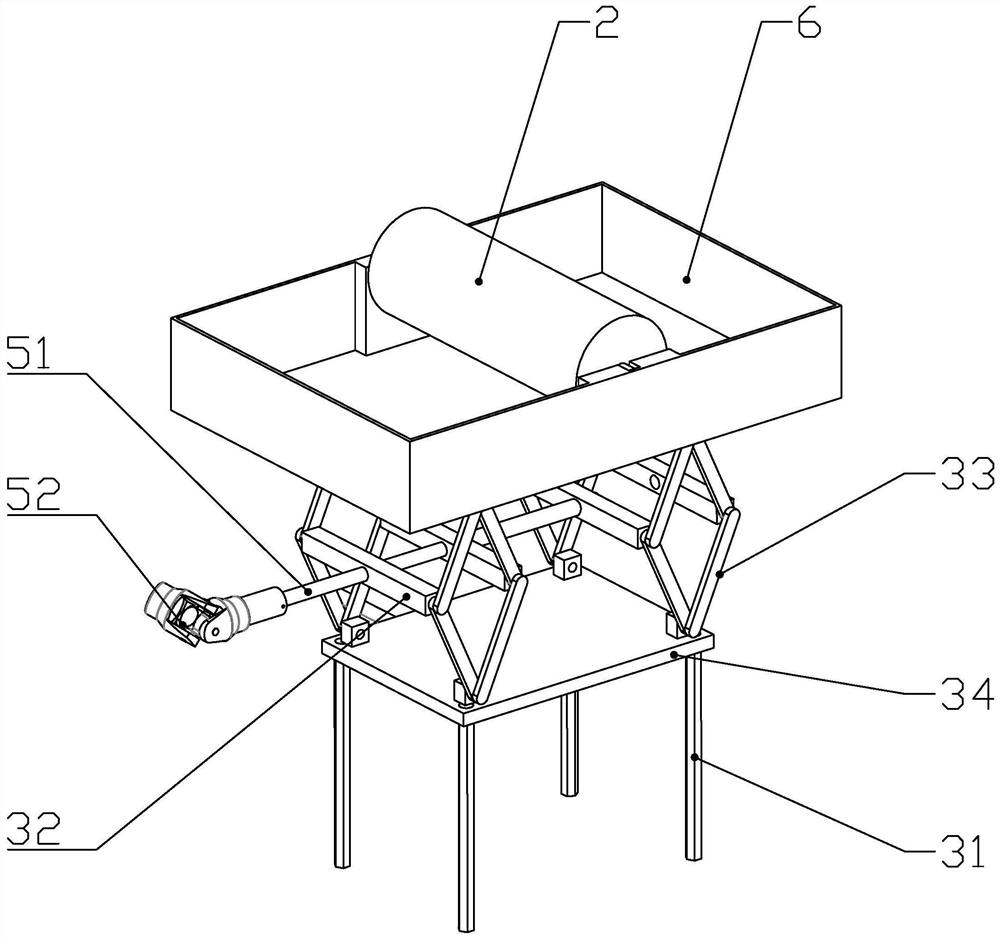

[0033]Such asfigure 2 As shown, the lifting mechanism 3 includes ...

Embodiment 2

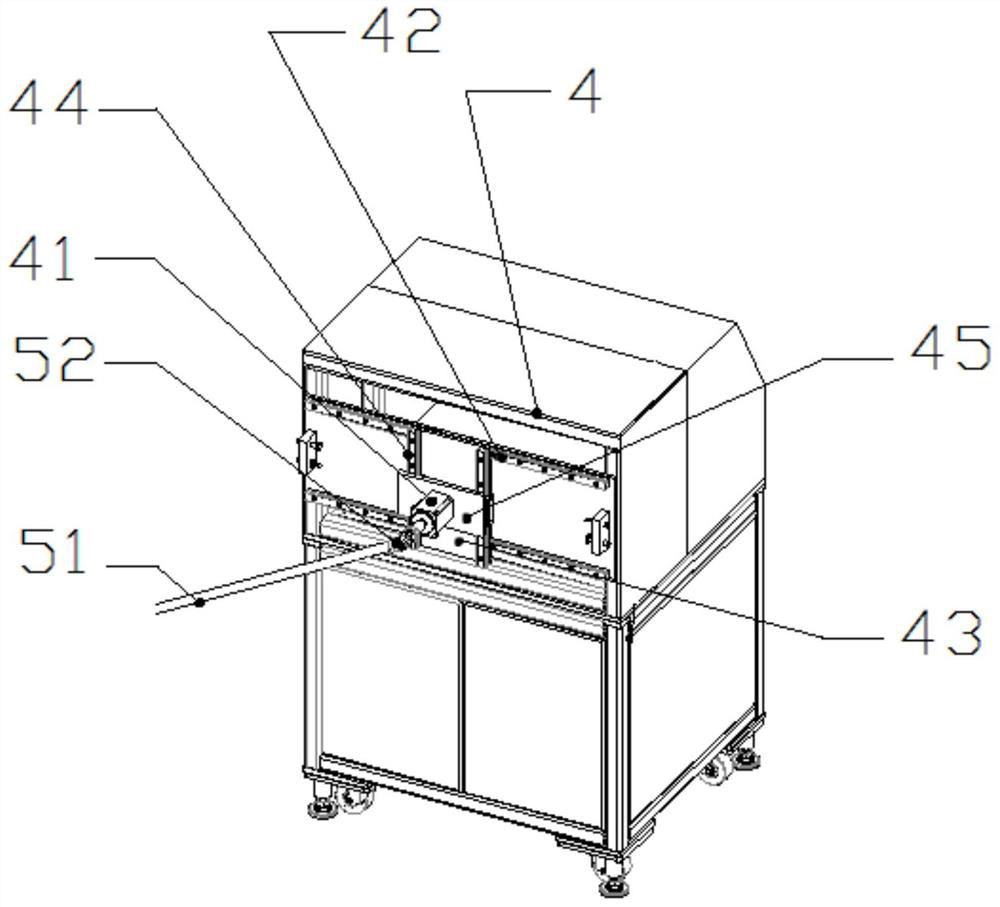

[0037]Such asimage 3 In the illustrated embodiment 2, a quartz tube expansion device has roughly the same structure as that of embodiment 1, except that the cooling water tank 6 includes an inner tank 61 and an outer tank 62 sleeved outside the inner tank 61, and a supporting wheel 2 It is rotatably arranged in the inner groove 61. The side wall of the inner groove 61 is provided with a first through hole 611 communicating with the outer groove 62. The two ends of the rotating shaft of the supporting wheel 2 extend outward, and the rotating shaft is provided with an adjusting plate spaced apart from the supporting wheel body. 22. The adjusting plate 22 is provided with a second through hole 21 corresponding to the first through hole 611 and communicating with the inner groove 61, and the supporting wheel 2 switches the communication state of the inner groove 61 and the outer groove 62 by rotating.

[0038]When expanding the tube, inject cold water into the inner tank and ice water into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com