Textile raw material sundry screening device

A screening device and raw material technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problem of difficult separation of impurities in textile raw materials, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

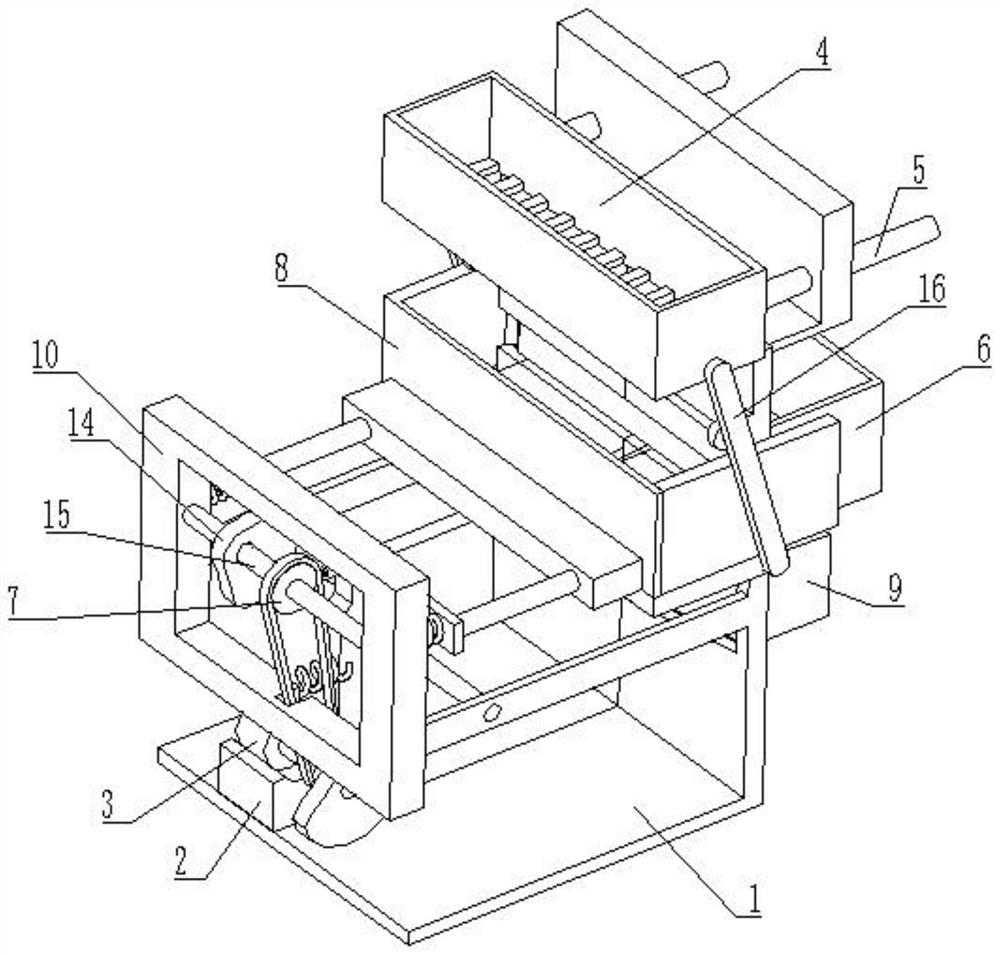

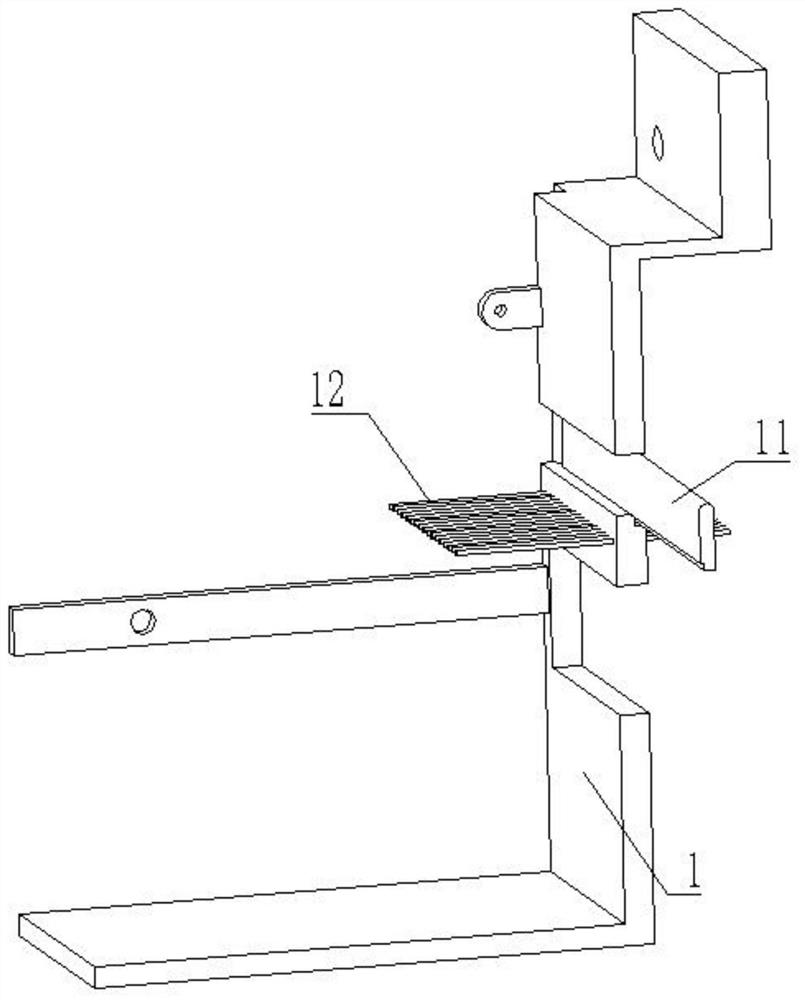

[0031] see Figure 1-7 , a screening device for sundries of textile raw materials, comprising a frame 1, the upper surface of the frame 1 is fixedly connected with an organic base 2, the upper surface of the frame 2 is fixedly connected with a motor 3, and the output end of the motor 3 is provided with a screening mechanism 7. The inside of the frame 1 is slidingly connected to the limit rod 5, the left end of the limit rod 5 is fixedly connected to the first screening box 4, the right side of the frame 1 is fixedly connected to the collection box 6, and the surface of the frame 1 is slidably connected to There is a second screening box 8, the inside of the second screening box 8 is fixedly connected with several filter rods 12, the surface of the filter rods 12 is slidingly connected to the inside of the frame 1, and the front portion of the frame 1 is fixedly connected with a frame 10.

[0032] In addition, the surface of the frame 1 is fixedly connected with a guide plate 1...

Embodiment 2

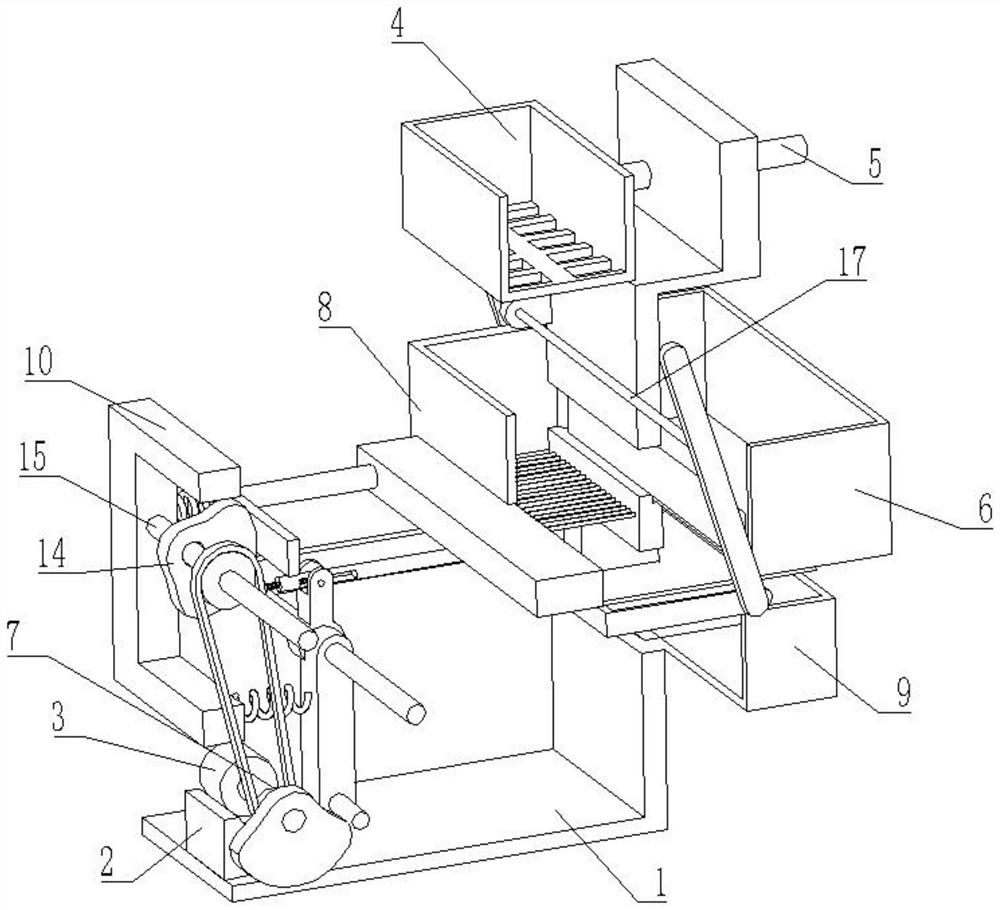

[0038] see Figure 1-8 , the internal rotation of frame 10 is connected with rotating shaft 15, and the surface of rotating shaft 15 is fixedly connected with second cam 14, and the surface of second cam 14 is provided with pushing device 77, and the output end of motor 3 and the surface of rotating shaft 15 are both A pulley 78 is fixedly connected, and the surfaces of the two pulleys 78 are connected through a belt drive.

[0039] Further, the pushing device 77 includes a push plate 771, the left side of the push plate 771 is fixedly connected with a push frame 772, the left side of the push frame 772 is fixedly connected with a spring two 773, and the left side of the spring two 773 is fixedly connected with the frame. On the right side of 10, the left and right movement of push plate 771 can well push raw materials into the inside of collecting box 6 from the position of dodge door 11 to realize separation and collection.

[0040] Furthermore, the number of spring two 773...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com