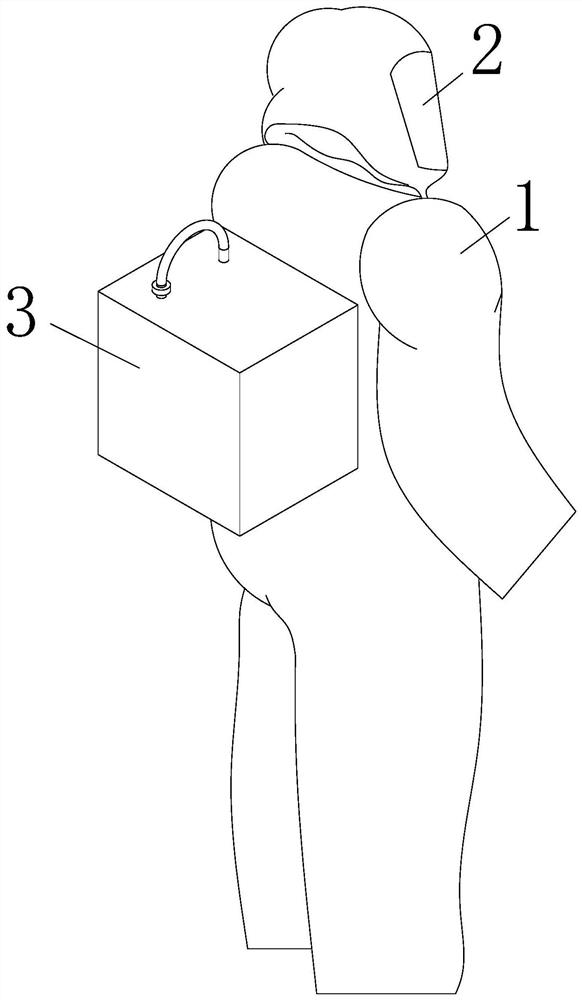

Automatic oxygen supply cooling garment

A technology for automatic oxygen supply and clothing, applied in the field of clothing, can solve the problems of increasing discomfort, wetting firefighters, and high cost, and achieves the effects of simple and reliable structure and improved cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

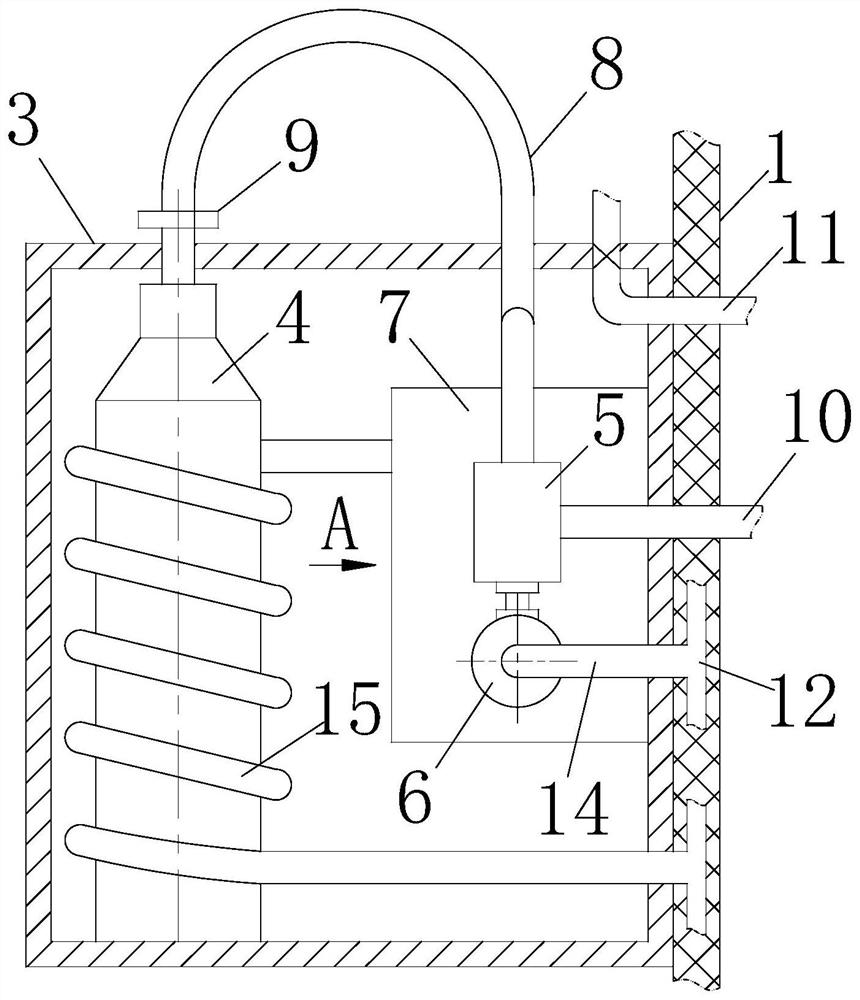

[0029] As an embodiment of the present invention, the third water pipe 15 is wound on the compressed oxygen cylinder 4; during work, the air pressure in the compressed oxygen cylinder 4 is reduced to absorb heat, so that the surface temperature of the compressed oxygen cylinder 4 is reduced, and from the branch water pipe 12 When the middle backflow water flows through the surface of the compressed oxygen cylinder 4, it will be cooled rapidly, and then when the water flows into the protective clothing 1 again, it can continue to cool down, realizing the automatic cooling of the circulating water and improving the cooling efficiency.

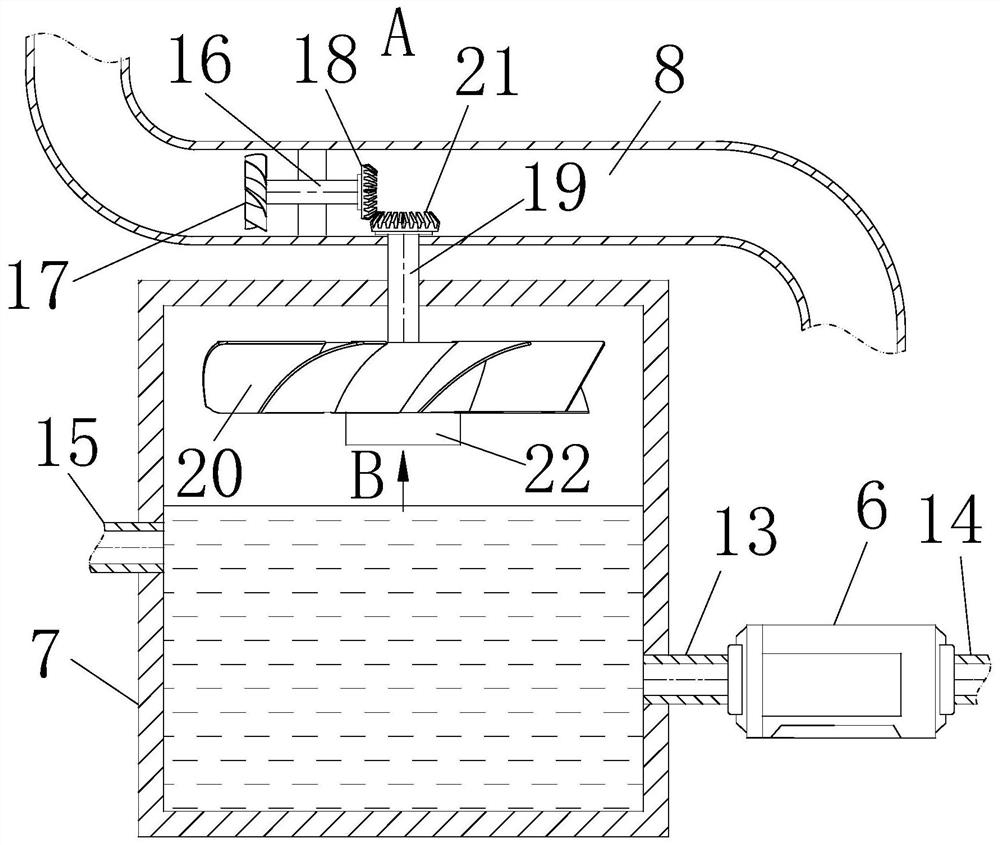

[0030] As an embodiment of the present invention, a first rotating shaft 16 is rotatably connected to the first air pipe 8 above the water tank 7 through a bracket; one end of the first rotating shaft 16 is fixedly connected to a first impeller 17, and the other end is fixedly connected to There is a first bevel gear 18; a second rotating shaft 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com