White tea processing airing device with screening function

A drying device and white tea technology, applied in the fields of filtering, tea drying, tea treatment before extraction, etc., can solve the problems of increasing the process, prolonging the delivery time, direct screening, etc., to achieve convenient drying, easy drying, and enhanced practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

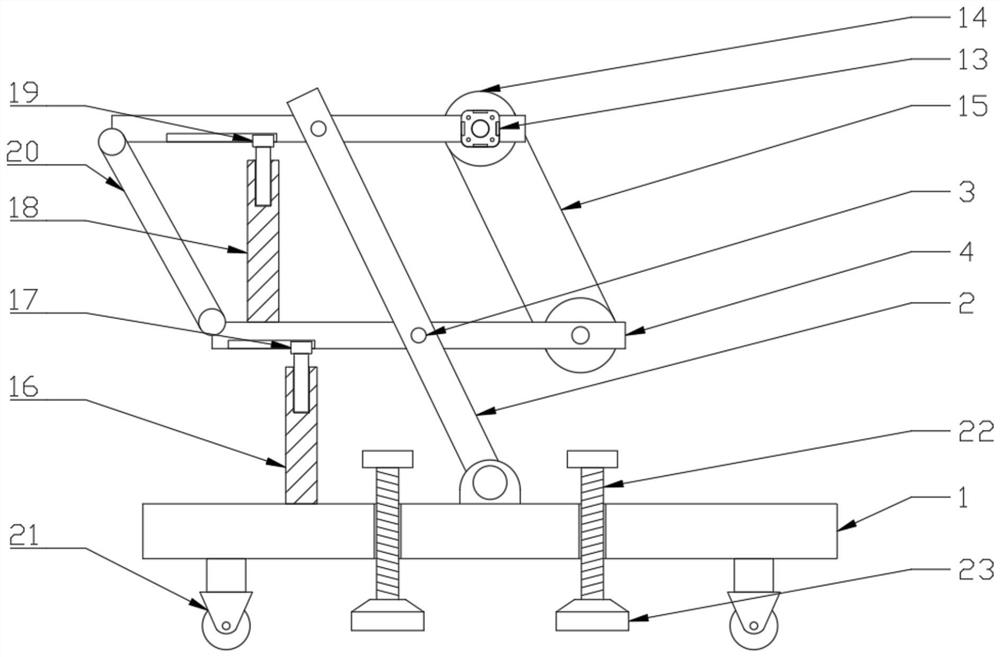

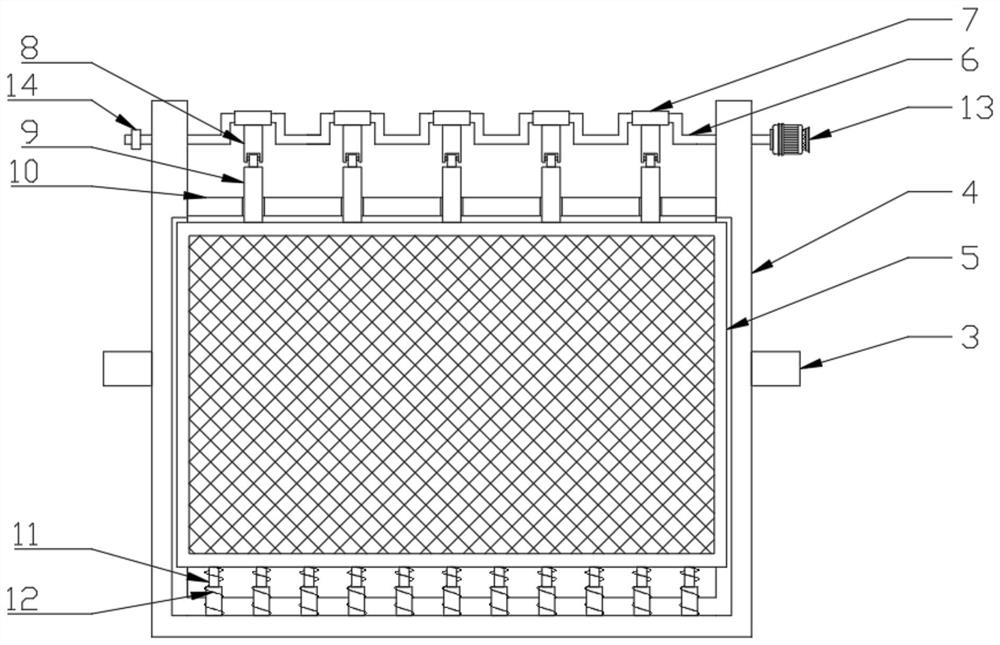

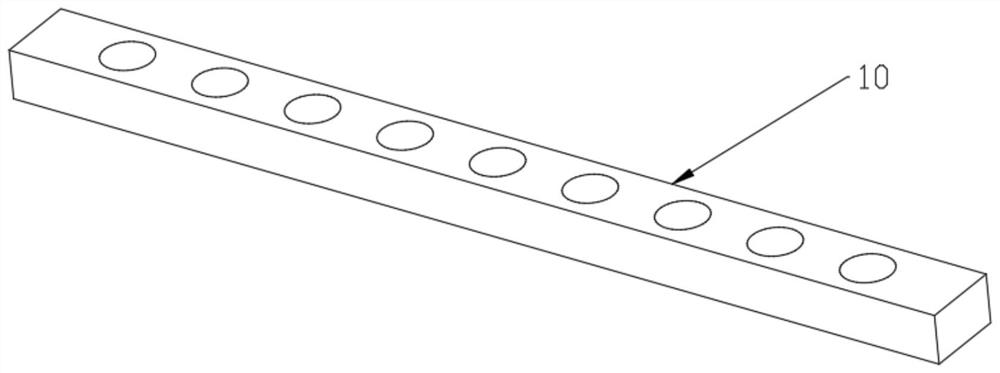

[0024]SeeFigure 1-3A white tea processing with a screening function, including a bottom plate 1, and the top surface of the bottom plate 1 hingedly symmetrically hingedly coupled with two fixing rods 2, and the two fixed rods are close to the top and the middle. The crossbar 3 is fixedly connected, and the outer surface rotation sleeve is provided with a fixing frame 4, and the fixing frame 4 is slidably connected to the drying plate 5, and the fixing frame 4 is provided with a drilling plate 5 reciprocating motion. The drive mechanism includes a crankshaft 6, a sleeve 7, a first link 8, a second link 9, a guide rod 10, a first stretch rod 11, and a spring 12, and both ends of the crankshaft 6 through a bearing. The rotation is connected to the right end of the fixing frame 4, and the outer surface of the curved section of the crankshaft 6 is provided with a sleeve 7, the sleeve 7 and the crankshaft 6 rotation, and the outer surface of the sleeve 7 is fixed to the first On the right...

Embodiment 2

[0029]In this example, further improvements made on the basis of Example 1. Specifically, as follows:

[0030]SeeFigure 1-3The bottom surface of the bottom plate 1 is actively connected to the universal wheel 21; the bottom plate 1 has four fastening bolts 22, and the fastening bolt 22 is fixedly connected to the support seat 23, by setting When the universal wheel 21 is convenient to move, when the tightening bolt 22 is rotated, the support seat 23 is adjusted, so that the support seat 23 is in contact with the bottom surface to increase the stability of the device.

[0031]In the end, it is: First, in the description of the present application, it is necessary to explain that the term "installation", "connected", "connection" should be used unless otherwise specified and defined, and "connect" should be a mechanical connection. Or electrically connect, or in the interior of the two pieces, it can be directly connected, "upper", "lower", "left", "right" or the like, only to indicate a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com