A new type of polyester polyol resin production dealcoholization equipment

A polyester polyol and resin technology, which is applied in the field of dealcoholization equipment for the production of new polyester polyol resin, can solve the problems of health impact on staff, expansion of noise transmission range, large vibration, etc., to facilitate promotion and improve stable efficiency , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

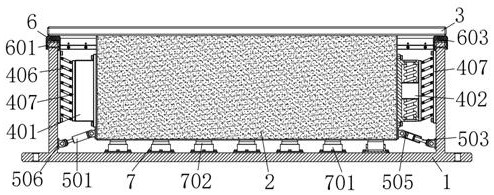

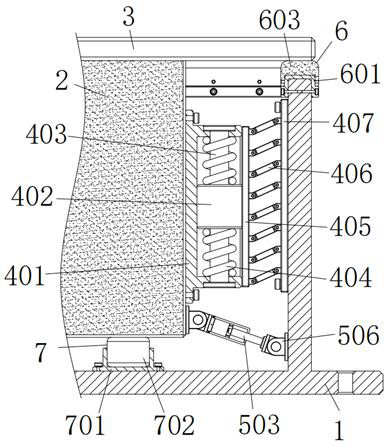

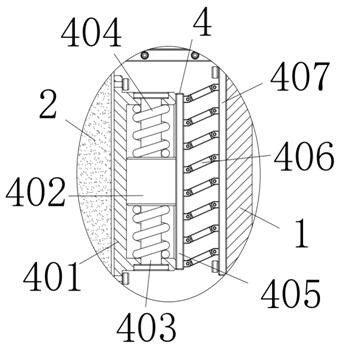

[0034] A new type of polyester polyol resin production dealcoholization equipment, including a base casing 1, a base top plate 3 is arranged above the base casing 1, and a connecting block is arranged between the base casing 1 and the base top plate 3 2. The upper surface of the connection block 2 is fixedly connected to the lower surface of the base top plate 3, the outer wall of the connection block 2 is socketed with the base casing 1, and the side wall of the connection block 2 is connected to the base through the first stabilizing mechanism 4 The inner wall of the casing 1 is connected; the first stabilizing mechanism 4 includes a sliding sleeve 401, a first sliding block 402, a first sliding rod 403, a spring 404, a first side plate 405, a connecting rod 406 and a second side plate 407; The outer wall on the left side of the sleeve 401 is fixedly connected to the base casing 1 by bolts, and the right side of the sliding sleeve 401 is provided with a first slider 402, and ...

Embodiment 2

[0036] As an option, see figure 1 and 4 , new polyester polyol resin production dealcoholization equipment, the lower side of the connecting block 2 is connected to the inner wall of the base casing 1 through the second stabilizing mechanism 5; the second stabilizing mechanism 5 includes a sleeve 501, a second Slider 502, second slide bar 503, damping hole 504, first connecting seat 505 and second connecting seat 506; the inside of casing 501 is provided with second sliding block 502, the outer wall of second sliding block 502 and casing 501 The inner wall of the second slider 502 is socketed, the second slider 502 is provided with a second slider 503, the top of the second slider 503 is fixedly connected to the bottom of the second slider 502, the outer wall of the second slider 503 is connected to the sleeve The tube 501 is slidingly socketed, and the bottom end of the second sliding rod 503 and the top end of the casing 501 are provided with a first connecting seat 505, an...

Embodiment 3

[0039] As an option, see figure 1 ,2 And 5, new polyester polyol resin production dealcoholization equipment, the top of the base casing 1 is equipped with a first support mechanism 6; the first support mechanism 6 includes a first support sleeve 601, a first support block 602 and a pin 603 The bottom end of the first support sleeve 601 is socketed with the top of the base casing 1, the first support sleeve 601 is fixedly connected with the top of the base casing 1 by bolts, and the first support sleeve 601 is provided with a second A support block 602, the bottom end of the first support block 602 is socketed with the top end of the first support sleeve 601, the side wall of the first support sleeve 601 is evenly fixed with a plurality of pin rods 603, and the outer walls of the plurality of pin rods 603 Both are socketed with the first support block 602;

[0040] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com